A Water Distribution System for proper usage and consumption of water was developed. The Level of water in main tank, the water flow from the pipeline system, leakage detection, bill generation of water usage, all of this is monitored/controlled through PLC and HMI. The HMI is easy and user friendly. The project concludes to be great benefit for water consumption.

To maintain the clean water resources has been a big issue. The problem is due to the improper management, distribution and monitoring system. We propose a water distribution system with automatic leakage detection and supply control. By applying the automation such as Programmable Logic and Control (PLC) and Human Machine Interface (HMI) we can minimize these problems. The proposed distribution system will ensure 24 hours availability of water to the user and the billing will automatic and will be based on the quantity consumed. Additionally the control unit can detect large leakages in order to prevent loss of resource. To maintain the clean water resources has been a big issue. The problem is due to the improper management, distribution and monitoring system. We propose a water distribution system with automatic leakage detection and supply control. By applying the automation such as Programmable Logic and Control (PLC) and Human Machine Interface (HMI) we can minimize these problems. The proposed distribution system will ensure 24 hours availability of water to the user and the billing will automatic and will be based on the quantity consumed. Additionally the control unit can detect large leakages in order to prevent loss of resource

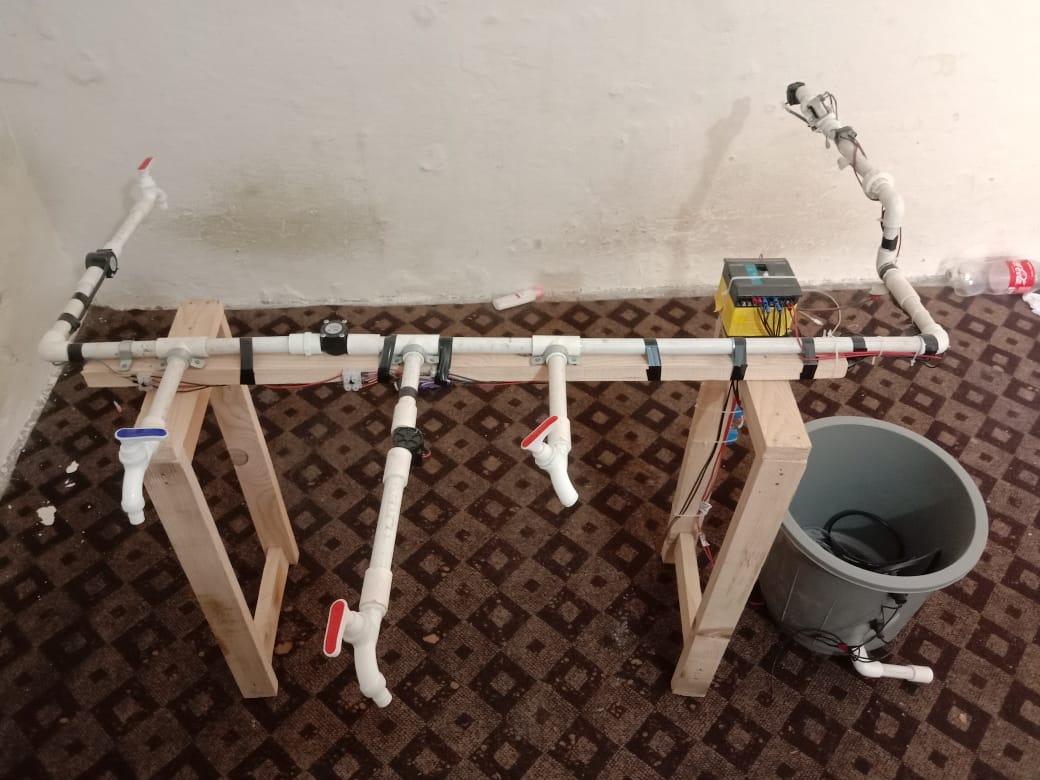

By monitoring the water level in the main tank by using oat switch we turn ON/OFF the motor pump to the main water tank. If the lower level switch gives the reading zero, then the motor will be turned ON otherwise it will remain OFF and the process will continue to check the condition of lower level switch. After that we check the condition of the upper level switch. If it gives the reading zero, then the motor will remain turned ON and the process will continue to check the condition of upper level switch. If the reading of upper level switch is high, then the motor will be turned OFF and the process will continue. One of the flow sensor is placed on the main pipe line nearer to the main water tank to measure the ow of water supplied and rest of them are placed on the distribution pipe lines near each consumers houses. These ow sensors will measure the ow of water for each consumer. Using that ow we calculate the water consumed by each user and on that basis, we would generate water bill.

By comparing the flow of water supplied and water consume, we detect the leakage through the pipe line. If any leakage occurs, the indicator will glow on the GUI and solenoid will be closed to cut o the water supply in order to prevent further wastage of water and damage of property. The water tank condition will be monitored by using the oat level switches that whether it is full or empty. The status of level switches will feedback to the PLC and it will actuate the MOTOR according to the Ladder Logic burned in its memory. All this process will be monitored and controlled by GUI on the laptop.