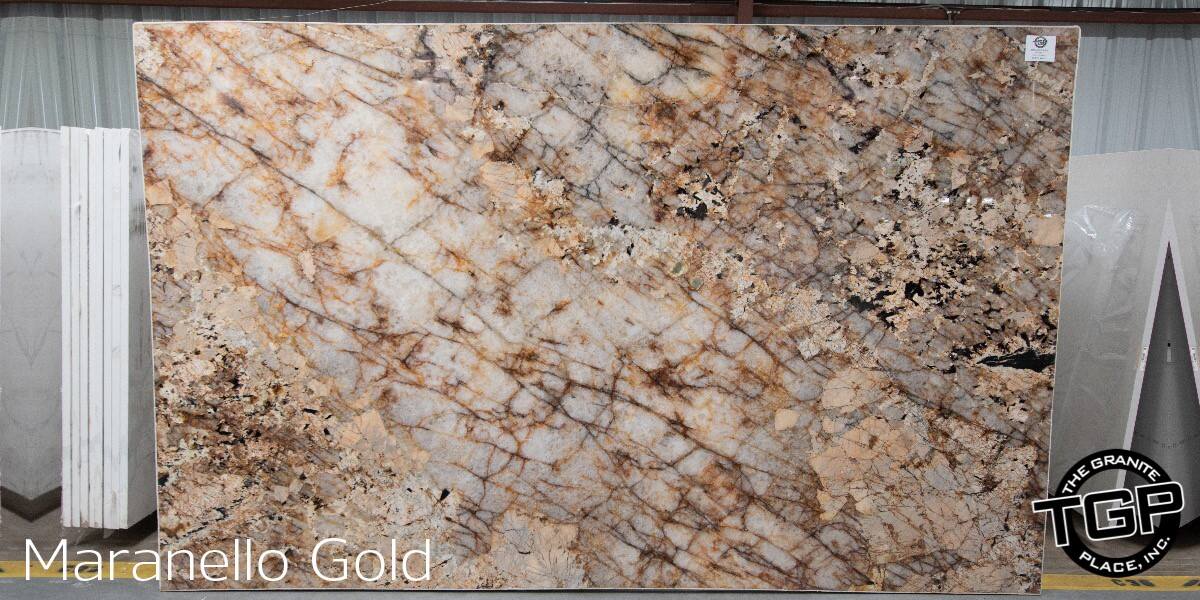

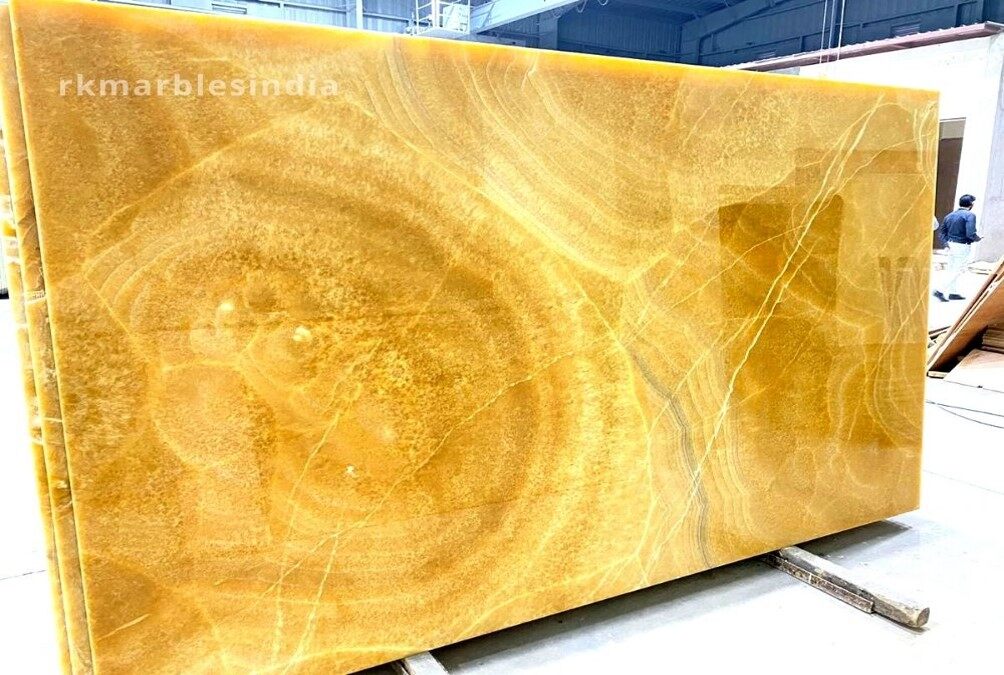

The newly started marble factory is a business that specializes in the production and processing of marble products. With a dedicated team of skilled craftsmen and advanced machinery, the factory aims to deliver high-quality marble products to meet the diverse needs of its customers.The factory sources raw marble blocks from trusted suppliers and utilizes cutting-edge technology to cut, shape, polish, and finish the marble to perfection. The range of products offered includes marble tiles, slabs, countertops, sculptures, and architectural elements.

Objectives

We have Following objectives of our business which are given below:

Customer Satisfaction

Product Excellence

Operational Efficiency

Market Penetration

Sustainability and Ethics

Socio-Economic Benefit

Not Available

Methodologies

Developing a new marble factory project involves several key steps. Here is a suggested methodology to guide you through the process:

Market Research and Feasibility Study:

Conduct market research to assess the demand for marble products in your target market.

Identify potential competitors and analyze their products, pricing, distribution channels, and market share.

Evaluate the feasibility of the project by considering factors such as raw material availability, labor costs, infrastructure requirements, and government regulations.

Business Plan Development:

Create a comprehensive business plan that outlines your project goals, target market, marketing strategies, operational processes, and financial projections.

Define your unique selling proposition (USP) to differentiate your marble products from competitors.

Determine the production capacity, initial investment required, and expected return on investment (ROI).

Location and Facility Selection:

Choose a suitable location for your factory considering factors like proximity to raw material sources, transportation infrastructure, availability of skilled labor, and access to target markets.

Determine the size and layout of the factory, including areas for production, storage, quality control, office space, and employee facilities.

Ensure compliance with environmental regulations and implement sustainable practices where possible.

Raw Material Procurement:

Identify reliable suppliers of high-quality marble blocks or slabs.

Establish long-term partnerships with suppliers to ensure a consistent supply of raw materials at competitive prices.

Develop a quality assurance process to verify the authenticity and quality of the marble received.

Production Processes and Equipment:

Determine the specific marble products you will manufacture, such as tiles, slabs, sculptures, or custom designs.

Define the production processes required for each product category.

Procure appropriate machinery and equipment, including cutting machines, polishing machines, shaping tools, and finishing equipment

Outcome

Not available