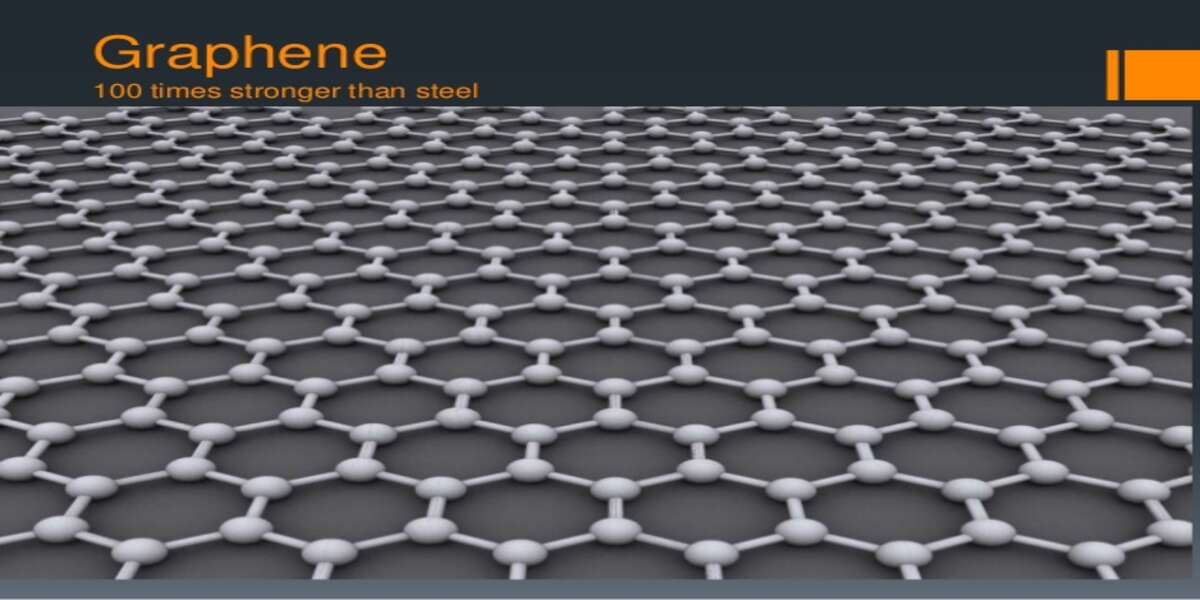

Thanks to its wide range of materials, high flexibility, and well-established manufacturing processes, concrete is one of the most widely used building materials on the planet. Different forms of concrete are made for various purposes using the right combination of materials. However, as modern concrete structures grow, traditional concrete technologies are no longer adequate. Cementations additives including soil granulated blast furnace slag (GGBFS), silica fume (SF), and fly ash have been extensively researched in the manufacture of hybrid cement systems over the last few decades (FA). These materials help to build a stable base by increasing the spreads between the mud and the joints, as shown by their superior mechanical properties. These overcrowded matrices, on the other hand, behave differently and less when exposed to high temperatures. Germination occurs because of sudden matrix breakup due to a lack of pore pressure dissipation, thermal inertia growth, or heat stress concentration. Behnood and Masood taught us how to use polypropylene fibers (PP) to reduce deposit. The PP fiber is not airtight and fuses at about 200 degrees Celsius. However, the existence of these holes poses a problem in terms of longevity. Steel and basalt fibers were also tested for crack reduction. Grip breaks these fiber bridges, which aid in maintaining a functional load. However, when these cables are correctly connected to the cement matrix and the total cost, there are issues. Cement materials are often broken, making them crack prone and devoid of usable properties. Nanotechnology is integrated into the cement binding to solve the problems described above. Carbon nano tubes (CNT), carbon nanofibers (CNFs), and graphite nano plates are examples of nano-carbonated nano materials (NCMs) that have shown promise in improving the mechanical, functional, and stable structure of headlines in current conditions (GNPs). Waqas et al. used carbon nanotubes (MWCNTs) to increase the long-term stability of hormones. The use of these nano-scale reinforcements, according to the scientists, not only solves heat gaps but also decreases thermal inertia. The very warm state of nanotubes causes a decrease in thermal inertia and equivalent thermal pressure dispersion. CNT and CNFs are present in the fire behavior of reinforcement moths, even though there is a lot of research on them. Graphite and platelets (GNPs) are studied in combination with high-temperature matrices in scientific literature. The small GNP bags contain graph layers of 0.34 to 100 nano meters in normal size. Graphene is a six-dimensional plane consisting of a single carbon layer and is frequently referred to as a 'sub structure unit. There is a net-like structure for the formation of GNPs composed of a hexagonal, multi-carbon convex plane with a graphical image of GNPs consisting of only a single layer of carbon atoms. As a result, GNP properties are almost the same as graphene.

Many researchers have combined the equipment, durability, power, and thermal conductivity of NPGs with a view to making the matrix more efficient, effective, reliable, robust. GNPs have advanced mechanical characteristics that contain high conductivity of heat and electricity like other carbonated nanomaterials. GNPs ($2/kg) are, however, less expensive than CNTs ($8/gramme). Studies have shown that GNP and cement blends have improved interactions Because of the pointed structure, cracks were blocked and deviated to micro and nano levels and a delay in crack formation due to the screening forces has been reported. In many matrix simulations, Bansal et al shared that agreement. They used 5% wt. of GNP and concluded that GNPs improved both their mechanical properties and their porosity. As a result, the GNP distribution is insufficient, the flexibility and modular module increased respectively of 27 percent and 68 percent compared to the controlled mix at 1.5% wt. of GNP. GNPs are thus a good alternative to other nanomaterials that cannot be dispersed in cement and are not just costly. Studies by Weina and Kamal revealed a 56% increase in bending strength and an 187% increase in energy consumption in comparison to the control samples. Ultra-high-performance concrete was observed with GNP impact. Both studies found that the cause for development is nano-particulate fragmentation and integrity. GNPs increase the cement matrix's thermal conductivity as shown by Xia Cui et al. Researchers have shown that the inclusion of GNPs increases the thermal propensity of cement-based combinations by 1% by up to 75% and cement-based combinations by 5% .Kalaitzidou et al. created an intuition similarly. During the investigation, the researchers studied the effect of GNPs on the incorporation of composite polymer containing GNPs.Research on carbon-based media covered by exposed concrete fire is scarce and limited to 1-days objects. No data published for the performance tests of 2-d nanocarbon materials in higher-temperature concrete matrices is expected to improve the connection to the bonding matrix. Therefore, an effort was made to test the fire tolerance of reinforced concrete with 2-d panels of graphite to close this research gap.

Nano-modified samples with absorbing power are included in the solid interconnection lock, indicating their ability to avoid cracking and retain inelastic deformities without significantly lowering capacity at higher temperatures. These enhancements can help to reduce fires caused by reinforced concrete joints, which are more susceptible to fires than other structures such as columns and cisterns. Recent research has attempted to fill the research void that has been identified. GNPs not only boost structures, but also have the thermal conductivity component, as seen in the studies above. This improvement in thermal conductivity will aid in the dissipation of thermal pressures and the reduction of thermal inertia in flammable concrete structures, all of which can have negative consequences. GNPs will, understandably, increase fire resistance. To date, however, there is no safe statistic for the properties of those modified fire-filled matrices. The ability to predict high-temperature structures, as well as increased testing data and analytics design, has been established. The mechanical, toughness, structure, and small structures of high-grade concrete converted at 800C to varying degrees of graphite nanoplatelets, which are presented as ambient fire retardants in the literature, are presented in this report (GNMPs). The remaining behaviors, which are widely used for fire testing and are based on this approach for most data on high temperature tests, have been studied.