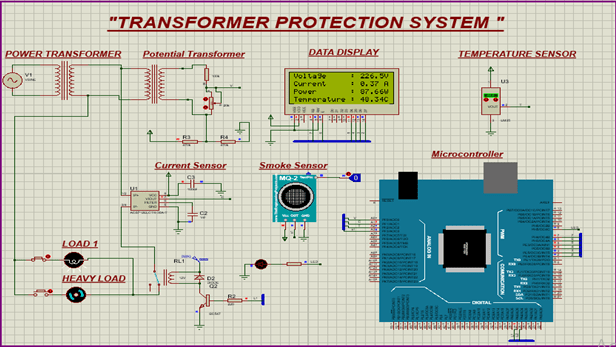

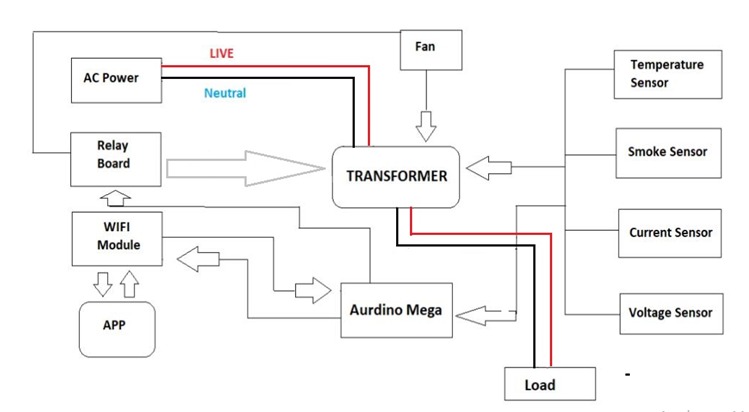

The main purpose of this project is the protection of transformer, and to improve the working of transformer. The main fault/problem that transformer faces is heating due to which the winding of transformer is burnt or damaged. In this project we use a mechanism to prevent all faults such as we use sensors and relays to prevent any damage. Also IOT base system help us to control the transformer from anywhere wirelessly.As a result transformer work more efficiently.

Objectives

1. Protection mechanism for Transformer.

2. Ensures timely detection and alerting for abnormal behavior.

3. Ensure the reliability and safety of the transformer.

4. Develop an IoT based system to monitor real time data.

5. Implement data backup procedures to prevent data loss in case of system failures or disasters. Set up a disaster recovery plan to quickly restore operations in the event of a major outage.

6. Ensure the system complies with relevant industry standards and regulations regarding data privacy, security, and machine safety. Keep abreast of any updates or changes to rules that may affect the project.

Socio-Economic Benefit

1. Remote Accessibility: Remote accessibility allows the user to monitor and manage data from anywhere.

2. Equipment Protection: Protection of equipment from damage and potential failure through advanced protective measures.

3. User-Friendly Interface: User friendly interface ensures ease of use and maximum utilization of system.

4. Integration with IoT Platform: Integration with IoT platform enables advanced analytics and optimization capabilities.

5. Improved Operational Safety: Improved operational safety through proactive monitoring and automatic shutdown mechanism.

6. Enhanced Efficiency: Enhanced efficiency by providing real-time insights into machine performance.

7. Reduced Downtime and Maintenance Cost: Reduced downtime and maintenance cost through predictive maintenance strategies.

Methodologies

1. Planning and requirements gathering

2. System design

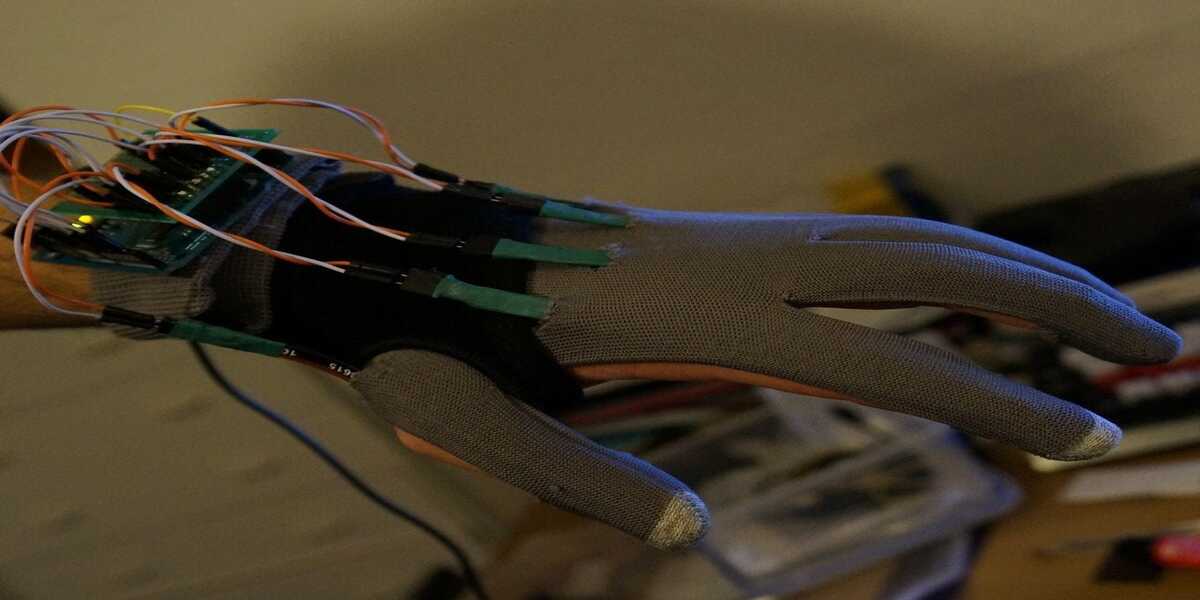

3. Sensor integration

4. Development of Monitoring interface

5. Algorithm development

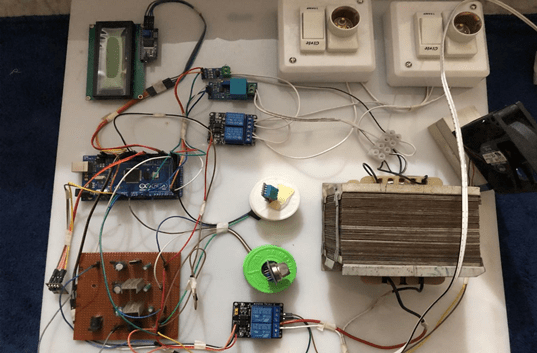

6. Hardware implementation

7. Software Development

8. Testing and validation

9. Deployment

10. Training and documentation

11. Maintenance and support

Outcome

1. Enhanced monitoring capabilities for voltage, current, temperature, and smoke.

2. Improved safety through timely fault detection and protection mechanisms.

3. Remote accessibility via the Blynk app for monitoring and receiving fault notifications.

4. Increased efficiency by minimizing downtime and optimizing maintenance.

5. Data-driven insights for performance optimization and decision-making.

6. Cost savings by preventing damages and optimizing maintenance schedules.