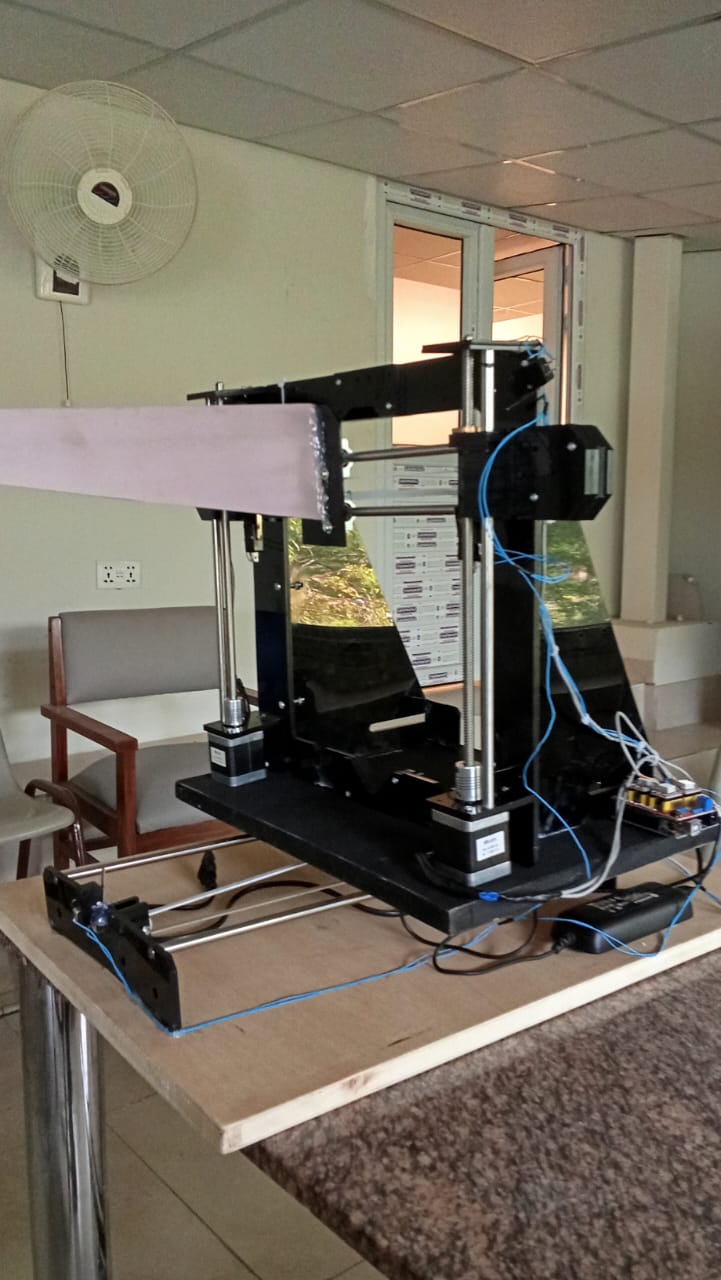

The 3D Numerical Control Motor Platform for Detection of Magnetic Field is a cutting-edge project aimed at advancing magnetic field measurement techniques. By incorporating precision probe positioning, three-dimensional control capabilities, a user-friendly graphical interface, and compatibility with standard Hall effect meters, this platform promises unparalleled accuracy and efficiency in magnetic field measurements. Its customizable range of motion and versatile applications across industries make it a groundbreaking tool for researchers, engineers, and scientists alike.

Objectives

The objective of the ”3D Numerical Control Motor Platform for Detection of Magnetic

Field” project is threefold:

1. Develop a sophisticated three-dimensional control platform capable of securely holding

and maneuvering the Hall effect meter’s probe.

2. Implement a user-friendly Graphical User Interface (GUI) for seamless interaction and

control of the platform.

3. Conduct comprehensive experimental verification and testing to validate the platform’s

functionality, accuracy, and reliability in magnetic field measurements

Socio-Economic Benefit

The 3D Numerical Control Motor Platform for Detection of Magnetic Field project offers significant socio-economic benefits:

Increased Efficiency and Productivity: By enhancing magnetic field measurement techniques, the project reduces time and resources required for conducting measurements. This increased efficiency translates into higher productivity for researchers, engineers, and scientists, leading to accelerated research and development processes.

Cost Savings: Improved accuracy in magnetic field measurements minimizes errors and reduces the need for repeated experiments or recalibration. This results in cost savings for research institutions, laboratories, and industries using magnetic field measurement technology.

Technological Advancement: The project contributes to technological advancement by introducing innovative solutions for precise probe manipulation and three-dimensional control. This fosters progress in scientific research and promotes the development of new technologies and applications.

Job Creation: The implementation and deployment of the 3D Numerical Control Motor Platform may create employment opportunities in various sectors, including manufacturing, software development, research, and technical support.

Industry Competitiveness: Industries relying on magnetic field measurement technology can gain a competitive edge by utilizing the advanced capabilities of the platform. This allows companies to innovate more rapidly, improve product quality, and stay ahead in the global marketplace.

Education and Training: The availability of advanced measurement tools like the 3D Numerical Control Motor Platform enhances educational and training programs in science, technology, engineering, and mathematics (STEM) fields. Students and professionals can gain hands-on experience with cutting-edge technology, preparing them for future careers in STEM-related industries.

Environmental Impact: Certain applications of magnetic field measurement, such as environmental monitoring and renewable energy research, can benefit from improved accuracy and efficiency. This contributes to better environmental management practices and the development of sustainable solutions.

Methodologies

The methodologies employed in the development of the 3D Numerical Control Motor Platform for Detection of Magnetic Field encompass various stages, ensuring a systematic and effective approach:

Requirement Analysis:

Conduct a comprehensive analysis of the requirements for the platform, including precision, range of motion, control interface, safety features, and compatibility with Hall effect meters.

Gather input from stakeholders, end-users, and domain experts to ensure all functional and non-functional requirements are captured accurately.

Design Phase:

Develop a conceptual design for the platform, incorporating numerical control techniques and motorized mechanisms for precise probe manipulation.

Design the graphical user interface (GUI) to enable user-friendly control and visualization of the platform's functions.

Prototype Development:

Fabricate a prototype of the platform using suitable materials and components, integrating motorized actuators, sensors, and computer interface modules.

Implement the GUI software to interface with the platform, allowing users to control probe movement and monitor magnetic field measurements.

Testing and Calibration:

Conduct rigorous testing of the prototype platform to validate its functionality, accuracy, and reliability in securely holding and maneuvering the Hall effect meter's probe.

Calibrate the platform's motorized actuators and sensors to ensure precise positioning and measurement consistency across different scenarios.

Experimental Verification:

Perform experimental verification tests using known magnetic field sources to assess the platform's performance in real-world conditions.

Compare measurement results obtained with the platform to reference measurements to evaluate accuracy and identify any discrepancies or improvements needed.

Feedback and Iteration:

Outcome

The outcome of the 3D Numerical Control Motor Platform for Detection of Magnetic Field project is a sophisticated and versatile tool for enhancing magnetic field measurement techniques. Here are some key outcomes:

Precision and Accuracy: The platform achieves sub-millimeter precision in probe positioning, ensuring highly accurate magnetic field measurements. With an accuracy requirement within ±0.1% of the measured magnetic field strength, it provides reliable data for various applications.

Three-Dimensional Control: The platform's motorized actuators enable precise control of probe movement along the X, Y, and Z axes, offering full three-dimensional control. This capability allows for comprehensive spatial coverage and flexibility in measurement scenarios.