With the growing population and escalating energy demands, the traditional reliance on fossil fuels poses significant challenges. In response to these challenges, our project focuses on the production of biodiesel from waste cooking oil (WCO), employing a novel Microbubble Mediated approach.The process begins by collecting waste cooking oil, which is abundant in households or restaurants. This oil holds the potential to be recycled into biodiesel, offering a sustainable solution to waste management and energy production. However, this project introduces a unique twist by employing the microbubble-mediated process. In parallel, conducted corrosion analysis on various engine materials, including copper, aluminum, and stainless steel. The immersion technique is employed to determine the corrosion rates of these materials when exposed to biodiesel blends.At last, Response Surface Methodology has been used for statistical optimization to find systematic results.

Objectives

Recognizing the advantages of renewable energy sources over conventional ones, the primary objective is to develop a setup for producing biodiesel from waste cooking oil (WCO). This biodiesel, derived from organic sources, offers a sustainable alternative to conventional diesel and can significantly reduce pollution emissions from engines.

Key goals include:

1. Developing a biofuel production plant equipped with the necessary apparatus and following strict safety protocols.

2. Producing biodiesel from WCO using a unique microbubble process, which involves premixing oil and catalyst, evaporating methanol, and reacting it with the oil-catalyst mixture. The resulting biodiesel is then separated, purified, and tested for properties.

3. Conducting corrosion analysis on engine materials like copper, aluminum, and stainless steel when immersed in biodiesel blends. This analysis is crucial for ensuring the viability and safety of biodiesel as a renewable fuel for transportation.

In addition to these primary objectives, biodiesel is a sustainable fuel alternative with benefits such as organic degradation, reduced toxicity, and improved air quality. By comprehensively understanding the impact of biodiesel on engine materials, we hope to contribute valuable insights to future research in transportation and renewable energy.

Socio-Economic Benefit

Addressing significant challenges like pollution and energy scarcity is crucial for global sustainability. As the world's population grows, the demand for energy increases. However, heavy reliance on fossil fuels like oil and gas exacerbates pollution and environmental harm. Therefore, finding cleaner, renewable energy sources is imperative.

The project focuses on creating biodiesel from used cooking oil, a resource often discarded after cooking. Converting this waste into vehicle fuel offers dual benefits: reducing waste and minimizing environmental impact.

Furthermore, the project positively impacts the economy and society. Establishing biodiesel production facilities generates employment opportunities and fosters economic growth. Additionally, utilizing locally available waste oil reduces dependence on costly imported fuels, enhancing economic resilience within communities.

Biodiesel usage also improves air quality by emitting fewer harmful pollutants compared to conventional diesel. This promotes community health and environmental sustainability. Thus, the project contributes not only to fuel production but also to creating a cleaner, healthier, and more prosperous world for all.

Methodologies

Methodology:

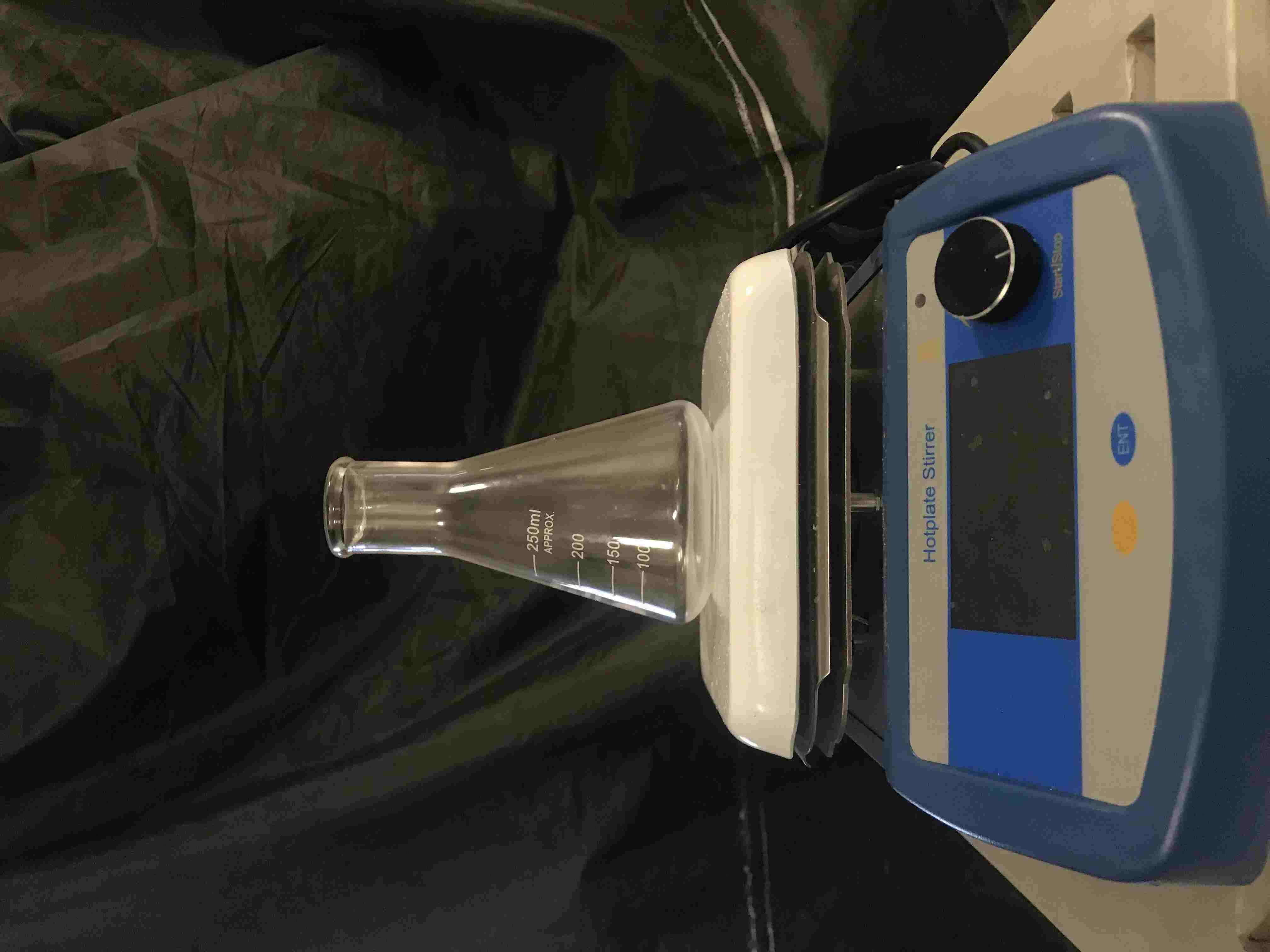

1. Setup Installation and Equipment Acquisition: The experiment required necessary equipment from various suppliers and cities. This included glassware like sintered funnels, round bottom flasks, beakers, and burettes, along with operational tools such as magnetic stirrers, heating mantles, and digital weight balances. Raw materials like waste cooking oil, methanol, and chemicals were procured for experimentation. Safety gear like masks, gloves, and glasses were also acquired.

2. Biodiesel Production Using Micro Bubble Mediate Method: The experiment began by mixing waste cooking oil with a catalyst called potassium hydroxide (KOH) using a magnetic stirrer. Methanol was added to a heated flask in a specific ratio with the oil and vaporized. The vapors passed through a sintered funnel, where they reacted with the oil and catalyst. This Micro Bubble Mediate method prevented reversible reactions and facilitated biodiesel production.

3. Purification of Biodiesel: The produced biodiesel underwent purification to remove impurities like methanol, catalyst residues, and water. This involved heating the biodiesel to vaporize methanol, washing it with warm distilled water, and adding anhydrous sodium sulfate to absorb any remaining water. The purified biodiesel was then filtered to obtain a clean product.

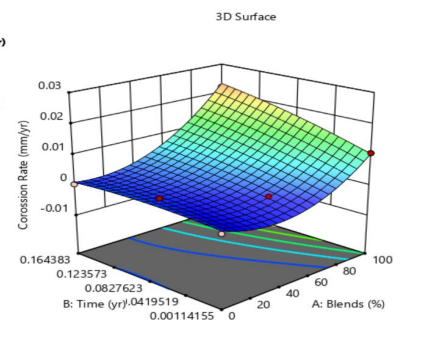

4. Corrosion Analysis of Engine Materials: Biodiesel's high level of free fatty acids makes it corrosive, necessitating corrosion tests before engine use. Engine materials such as copper, stainless steel, and aluminum were subjected to immersion in different biodiesel-diesel mixtures for varying durations using the immersion technique. Each material underwent cleaning, labeling, weighing, immersion, cleaning, and re-weighing to measure corrosion.

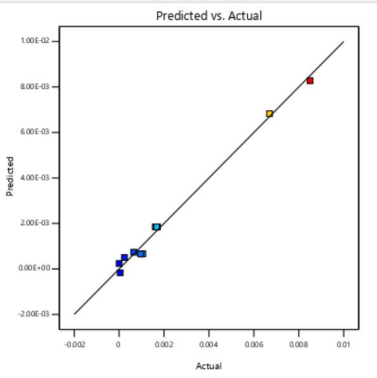

5. Statistical Analysis and Optimization: Response Surface Methodology (RSM) was employed to optimize experimental parameters like immersion duration, material type, and corrosion rates. This statistical analysis helped us understand the corrosion behavior of engine materials in biodiesel mixtures over time, aiding in decision-making and process improvement.

Outcome

The project yields several significant outcomes.

• Firstly, it addresses the pressing issues of pollution and energy scarcity by offering a sustainable solution in the form of biodiesel production from waste cooking oil. By recycling this waste, we not only reduce environmental pollution but also contribute to energy independence by producing a renewable fuel source locally. Additionally, the project fosters economic benefits by creating opportunities for waste reduction and income generation through the sale of waste cooking oil and biodiesel.

• Moreover, the corrosion analysis conducted on engine materials provides valuable insights for automotive manufacturers. By understanding how different materials interact with biodiesel blends, manufacturers can enhance engine durability and safety, ultimately leading to longer-lasting engines and reduced maintenance costs for vehicle owners. This aspect of the project contributes significantly to the advancement of transportation technology and the promotion of sustainable energy solutions.

• Furthermore, the educational value of the project is substantial. It provides students and professionals with interdisciplinary learning opportunities in chemistry, mechanical engineering, and materials science. Through collaboration and knowledge sharing, individuals from diverse backgrounds can develop innovative solutions for environmental challenges and contribute to the promotion of sustainable practices. Ultimately, the project catalyzes raising awareness about sustainability and inspiring future generations to pursue solutions that benefit both society and the environment.