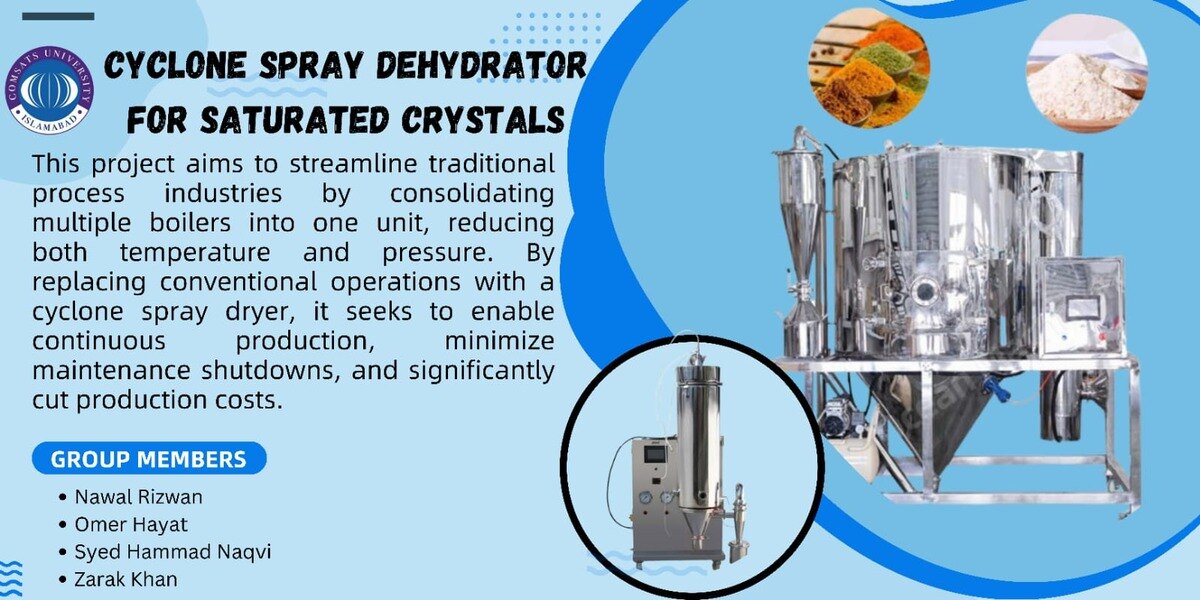

A transformative project for the sugar industry proposes consolidating boilers, reducing temperature and pressure, and integrating cyclone dryers to tackle key challenges. By streamlining operations and enhancing energy efficiency through consolidated boilers, alongside adopting lower temperature and pressure settings, the project aims to minimize resource inefficiencies and maintenance complexities, leading to cost savings and reduced downtime. Additionally, the adoption of cyclone dryers offers an efficient and sustainable alternative, promising significant energy savings, reduced wastage, and improved product quality, while facilitating seamless integration into existing production lines. Ultimately, the project targets continuous production with minimal maintenance shutdowns, ensuring long-term competitiveness and cost-effectiveness in the sugar industry.

Objectives

The project aims to streamline heating processes by consolidating multiple boilers into one unit, enhancing energy efficiency and reducing maintenance costs. Lowering boiler temperature and pressure improves safety, energy savings, and equipment longevity. Introducing cyclone dryers replaces conventional drying methods, reducing energy consumption and carbon footprint while improving drying performance. These changes facilitate continuous production, minimizing maintenance shutdowns and enhancing productivity. Overall, the project aims to reduce production costs, improve product quality, and enhance competitiveness in the market.

Socio-Economic Benefit

Job Creation and Economic Growth:

Implementing the project could lead to job creation in several ways. Construction, installation, and maintenance of the new boiler system, cyclone dryers, and associated infrastructure could generate employment opportunities. Additionally, increased efficiency and productivity within the facility could support business growth, potentially creating more jobs in production, maintenance, and other related areas. This, in turn, contributes to local economic development and prosperity.

Cost Savings for Businesses and Consumers:

By optimizing heating and drying processes, businesses can reduce production costs. Lower energy consumption, decreased maintenance needs, and improved efficiency translate to cost savings for the company. These savings can potentially be passed on to consumers through lower prices, contributing to improved affordability and consumer welfare.

Environmental Sustainability:

Transitioning to more efficient and environmentally friendly technologies, such as cyclone dryers, reduces the facility's carbon footprint and overall environmental impact. This can lead to improved air quality, reduced greenhouse gas emissions, and conservation of natural resources. Communities benefit from a healthier environment and may experience fewer health issues associated with pollution, contributing to overall well-being.

Energy Efficiency and Resource Conservation:

Lowering boiler temperature and pressure, consolidating boilers, and adopting cyclone dryers all contribute to improved energy efficiency. This not only reduces operational costs for the facility but also conserves energy resources. By consuming less energy, the project contributes to energy security and reduces dependence on fossil fuels, which may have geopolitical and economic implications at larger scales.

Enhanced Competitiveness and Innovation:

Companies that embrace innovative technologies and processes often gain a competitive edge in their respective industries. By implementing this project, the facility may become more competitive due to improved efficiency, reduced costs, and enhanced product quality. This can attract investment, encourage innovation, and stimulate economic growth within the region.

Community Well-being and Social Cohesion:

As the project promotes economic growth, job creation, and environmental sustainability, it can contribute to overall community well-being and social cohesion. Stable employment opportunities, cleaner air, and a thriving local economy can improve residents' quality of life and foster a sense of pride and belonging within the community.

Methodologies

Filtration (Extraction):

The process begins with filtration, which involves passing the raw material or solution through a filtration system to remove any solid impurities or particulate matter. This step ensures that the solution is free from contaminants before further processing. Filtration can be achieved using various methods such as gravity filtration, vacuum filtration, or pressure filtration, depending on the characteristics of the solution and the desired level of purity.

Boiling of Filtered Solution:

After filtration, the purified solution is then subjected to boiling. Boiling involves heating the solution to its boiling point, causing the solvent to evaporate and leaving behind the desired solute or substance in a more concentrated form. This process is often carried out in a boiler or heating vessel, where controlled heating is applied to achieve the desired level of concentration.

Cyclone Dryer of Pre-Boiling Solution:

Instead of conventional drying methods, such as centrifugal drying, the project utilizes a cyclone dryer for drying the pre-boiling solution. A cyclone dryer operates based on the principle of centrifugal force, where the solution is introduced into a cylindrical chamber and subjected to rapid rotation. This rotation creates centrifugal force, which separates the moisture from the solution, allowing it to be evaporated or removed through an outlet. Cyclone dryers are known for their efficiency and are often used in industries where rapid and effective drying is required.

Cooling and Collection of Crystals:

Once the solution has been boiled and dried, it is then cooled to facilitate the formation of crystals. Cooling the solution causes the solute to precipitate out of the solution, forming crystals. The crystals are then collected using appropriate methods such as filtration, centrifugation, or sedimentation. Cooling can be achieved through various means, including air cooling, water cooling, or refrigeration, depending on the specific requirements of the process.

Product:

The final step of the methodology is the collection and packaging of the product, which consists of the crystalline substance obtained from the solution. Depending on the application, the product may undergo further processing or refining before being packaged and distributed to customers. The product can vary widely depending on the initial raw material and the specific requirements of the end-user, ranging from pharmaceuticals to industrial chemicals to food ingredients.

Outcome

Consolidation of Boilers:

By consolidating multiple boilers into one unit, the facility reduces its operational complexity and maintenance requirements. This consolidation streamlines the heating process, leading to better efficiency in energy usage and reduced maintenance costs associated with multiple boiler units.

Lower Boiler Temperature and Pressure:

Lowering the boiler temperature and pressure enhances safety and reduces the risk of accidents or equipment failures. This not only improves workplace safety but also lowers energy consumption and operational costs, contributing to the overall sustainability of the facility.

Replacement of Conventional Operations with Cyclone Spray Dryer:

Introducing a cyclone spray dryer in place of conventional centrifugal and boiler operations offers several benefits. Cyclone spray dryers are known for their efficiency in converting liquid or slurry feed into dried powder form. They typically require less energy compared to traditional drying methods, leading to cost savings and improved environmental sustainability. Additionally, cyclone spray dryers facilitate continuous production, reducing the need for maintenance shutdowns and enhancing overall productivity.

Achievement of Continuous Production with Reduced Costs:

Implementing the project objectives leads to continuous production with minimal maintenance shutdowns and reduced production costs. The streamlined operations, lower energy consumption, and improved efficiency contribute to enhanced productivity and cost-effectiveness. Continuous production minimizes disruptions, ensuring a steady supply of products and potentially increasing revenue for the facility.

Resource Optimization and Sustainability:

By embracing innovative technologies like cyclone spray dryers and optimizing processes, the facility reduces its reliance on land, energy, and raw material resources. This optimization enhances sustainability by minimizing environmental impact and conserving natural resources. Furthermore, the ability to accept alternative raw materials such as sugar beet or fruits expands the facility's resource options, potentially improving economic resilience and diversification.

Market Competitiveness and Diversification:

The adoption of advanced technologies and sustainable practices enhances the facility's competitiveness in the market. By offering high-quality products at reduced costs, the facility can attract more customers and expand its market share. Additionally, the ability to process alternative raw materials broadens the facility's product portfolio, enabling diversification and resilience against market fluctuations.