The successful production of High-Density Polyethylene (HDPE) pipes is vital for various industries, and Newtech Pipe Islamabad has taken up the mantle of ensuring quality and reliability in this domain. However, in the manufacturing process of HDPE pipes, maintaining consistent inner diameter poses a significant challenge. This challenge stems from a multitude of factors including variations in cooling rates, die swell, and the skill level of operators.After the pipes have been manufactured, one of the primary challenges is ensuring that their inner diameter remain consistent and free from eccentricity. Industry struggles with making synthetic polymer pipes with exact inner diameters because they often end up with unevenness caused by eccentricity during the manufacturing process. The Aim of this project is to develop an innovative machine to address the industry challenges associated with achieving precise inner diameters in synthetic polymer pipes.

Objectives

Develop a cost-effective and time-saving solution that effectively addresses eccentricity-related issues.

This version breaks down the objective into a specific challenge and desired solution characteristics:

• Challenge: We identify that eccentricity is causing problems within the industry.

• Solution Focus:

o Cost-Effective: The solution should be achievable within budget constraints.

o Time-Saving: The solution should be implemented and operational quickly to minimize disruption or delays.

Socio-Economic Benefit

Our project, "Development of a Novel Co-Eccentric Precision Machining of Synthetic Polymer Pipes," directly aligns with Sustainable Development Goal 9 (SDG 9). By advancing manufacturing processes for synthetic polymer pipes, our project contributes to building resilient infrastructure and promoting inclusive industrialization. The innovative machining technique that is developing enhances the reliability and longevity of infrastructure systems while fostering innovation in the field. Ultimately, our project supports the goals of SDG 9 by improving access to high-quality pipe solutions and driving progress in industrial sectors reliant on durable pipe infrastructure.

Methodologies

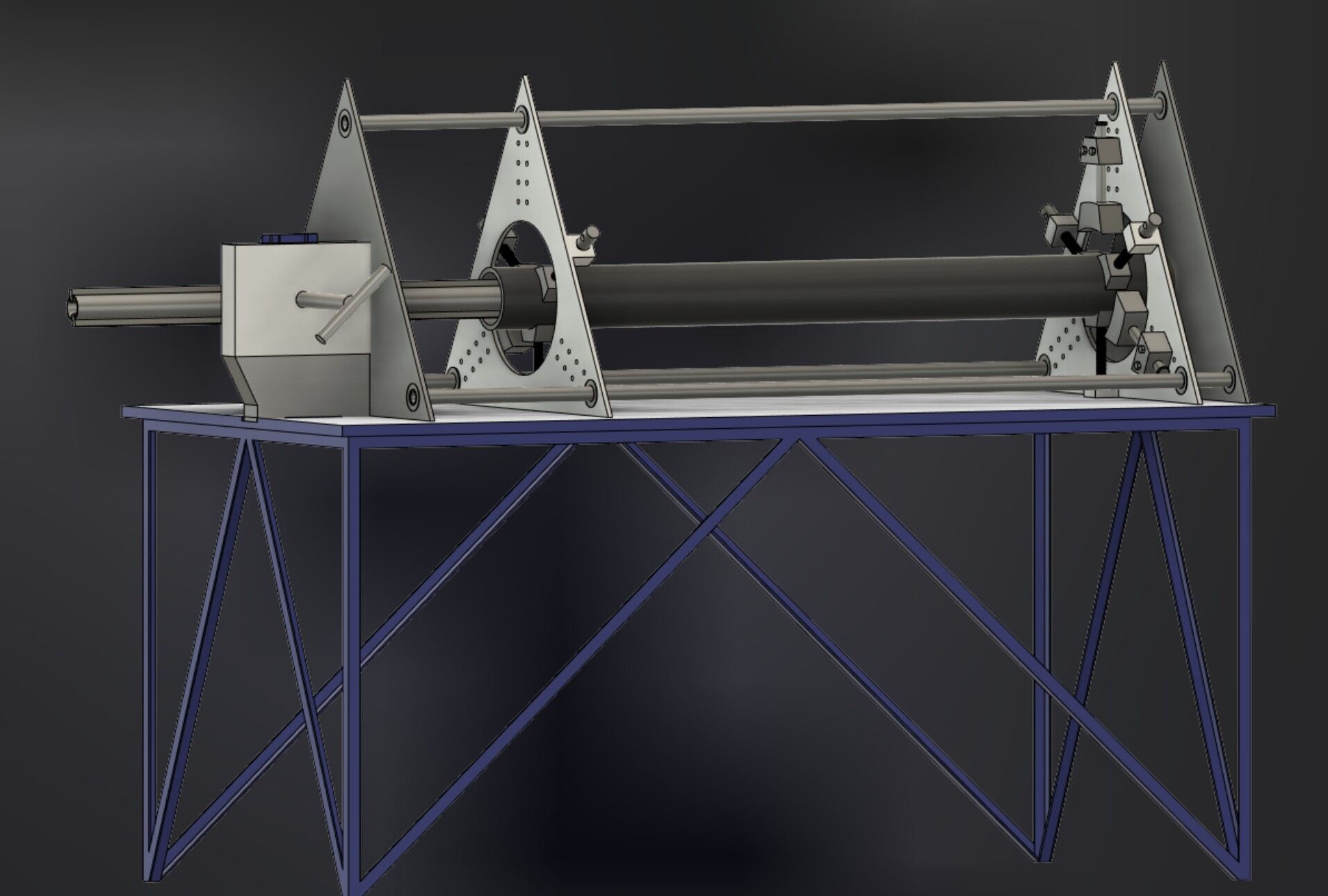

A precision machining system designed for achieving accurate inner diameters in synthetic polymer pipes features a co-eccentric configuration. This system incorporates four plates, with two fixed and two movable plates. The movable plates serve as chucks to securely grip an HDPE pipe, utilizing fixed and movable jaws for this purpose. The cutting tool employed ensures precise inner diameters in the HDPE pipe. Manual control is applied for transverse motion, with a controller and wheels facilitating internal pipe manipulation.

Outcome

Co-Eccentric Precision Machining: This is a manufacturing technique used to shape or refine materials with high precision. "Co-eccentric" likely refers to the simultaneous machining of two surfaces that are not concentric (not sharing the same center), which can be a challenging task requiring precise control and synchronization.

Enhancing Manufacturing Efficiency and Accuracy: The purpose of developing this new method is to improve the manufacturing process for synthetic polymer pipes. "Efficiency" suggests that the method helps in producing pipes more quickly or with less waste, while "accuracy" implies that it ensures the dimensions and specifications of the pipes are consistently met to a high degree of precision.