A linear motor is an electric motor that has had its stator and rotor "unrolled", accordingly, rather than creating a torque (pivot), it delivers a linear force along its length. In any case, linear motors are not really straight.

Project Objective

•Developing a linear motor.

•Developing a contact free propulsion system with the help of linear motor.

•To achieve magnetic ability, so the rotor travels on the path of permanent magnet.

•To achieve Nano scale precision

Socio-economic Benefits

·Usable and controllable normal forces, especially for magnetic levitation systems.

·Low maintenance requirement of wheel sets and rails on account of the contact free propulsion force.

·They are capable of high acceleration, precise positioning.

·Capability to produce a direct thrust, without any conversion of rotational into translational energy, independent of the adhesion factor between wheel and rail.

·Less Maintenance required, less friction so less lubrication required.

Project Methodology

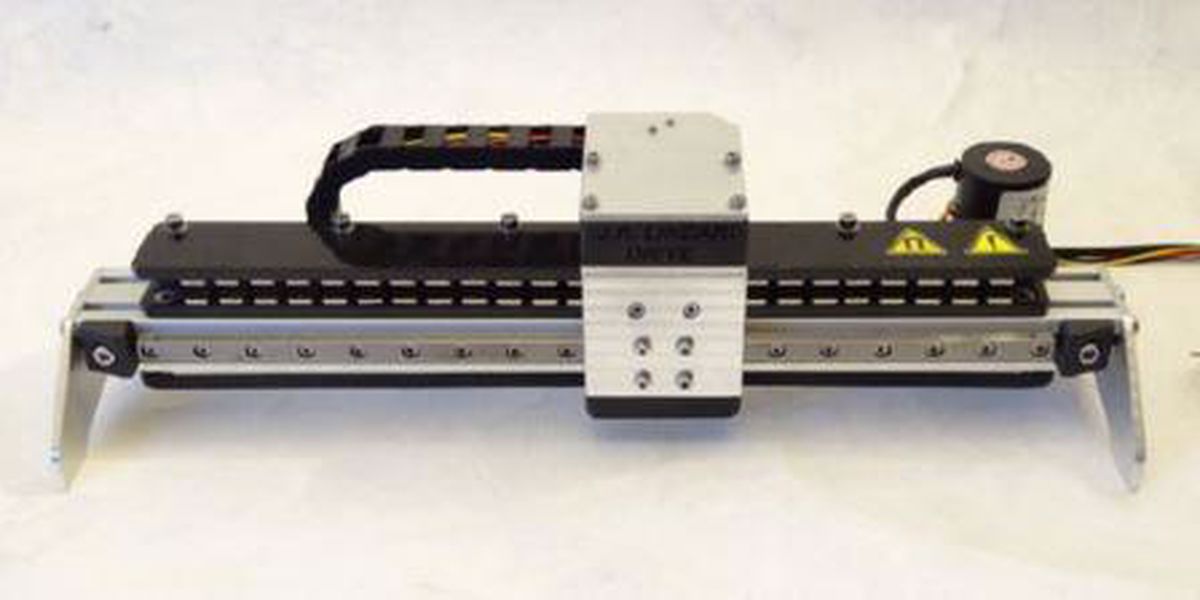

The working principle of the linear motor being studied is depicted. It is comprised of two main parts: · a number of base-mounted permanent magnets forming the stator; · a translator (as counterpart of the rotor in a rotating motor) formed by a number of iron-core coils. By applying a three-phase current to three adjoining coils of the translator, a sequence of attracting and repelling forces between the poles and the permanent magnets will be generated. This results in a thrust force experienced by the translator. Basically, the motor is a synchronous permanent-magnet motor with electronic commutation.

Project Outcome

The importance of nano-machining processes is continually increasing in a wide range of industries. In particular, the demands for machining with stable nanometer order accuracy in a wide work area have recently increased in the electronics and automotive industries. In order to meet such industrial requirements, it is necessary to develop an ultraprecision machine tool based on a new design concept. Therefore, in this study, a novel linear motor-driven aerostatic planar motion table system was developed for nano-machining. The results of actual machining tests confirmed that the developed table system has a remarkable performance.