Project Objective: -

1- The main objective of the study was to see how different welding tools affected the mechanical properties of similar AA6061 weld joints. We use two different tools material ( HSS and Steel H13 ) and three different shapes(Cylindrical, Square, Cylindrical Threaded ) to check the properties

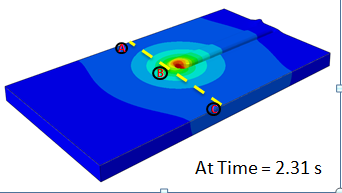

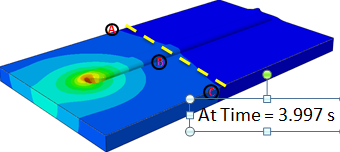

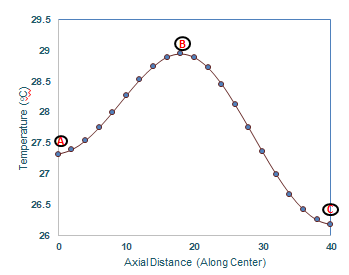

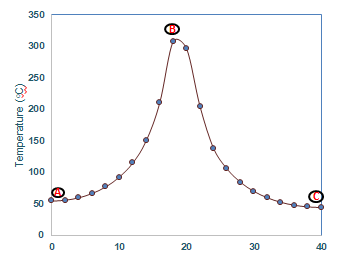

2- Six different simulations were performed on Abaqus software to determine the effect of the process on the mechanical properties of the weld.

3- Similarly six plates were welded using FSW to investigate the mechanical properties like Temperature Distribution, Stress Distribution and Weldability.

4- Specimens were fabricated for data collection(that include Tensile and Impact test).

5- Then compare the result that we get from Abaqus Software and from Physical testing

Socio-economic Benefits: -

1- Improved safety due to the absence of toxic fumes and molten splatter.

2- FSW uses a non-consumable tool, no filler wire is required.

3- Vertically, horizontally, radially, and in a circular run, friction stir welding can be done. It provides more freedom in operating positioning than other welding techniques. The base material, on the other hand, must be firmly attached to the fixed position.

4- The welding joint governed by FSW better mechanical characteristics than other joining operation.

5- In a single pass friction stir welding, the joint formation velocity is better than other fusion welding processes.

6- Lower setup costs and less training

Project Methodology: -

Phase 1: - Literature Review and Market Survey

Phase 2: - Installation and learning of simulation software's .

Phase 3: - Procurement of Material for Tool fabrication and aluminum plates for welding

Phase 4: - Investigation of weldability on simulation software

Phase 5: -FSW process and specimen fabrication

Phase 6: - Test performance and data collection

Project Outcomes: -

In other types of welding can’t produce high quality welding in short cycle of time. In other welding have a lower tensile strength, hardness and micro-structural properties. So in these welding we have a better mechanical properties of weld will come as compare to other welding. It have a lower setup cost.