This project demonstrates a method by which we can develop a prototype on which our aims to make a brown crystal sugar from sugarcane. This project demonstrates a method by which we can develop a prototype on which our aim is to make a brown crystal sugar from sugarcane.This involve six major processes number one is milling a process of crushing the sticks of sugar cane to extract the juice.Next is, clarification in clarification process sludge, mud, suspended and colloidal particles are removes by chemical compounds. Next is filtration in filtration solution is further filtered in a device called separator. Next is evaporation In evaporation water is evaporated from the solution after evaporation we obtain a brown sugar in order to convert brown sugar to white crystal sugar centrifugal will take place. In centrifugal sugar crystals are made with the help of centrifugal spinner and last one is drying the sugar extracted from sugar cane.

Objective

We are dealing with a real world problem. We are making this for a short setup ,this project demonstrates that we developed a prototype on which our aim is to make brown sugar from sugarcane. This involve following major processes,

Clarification

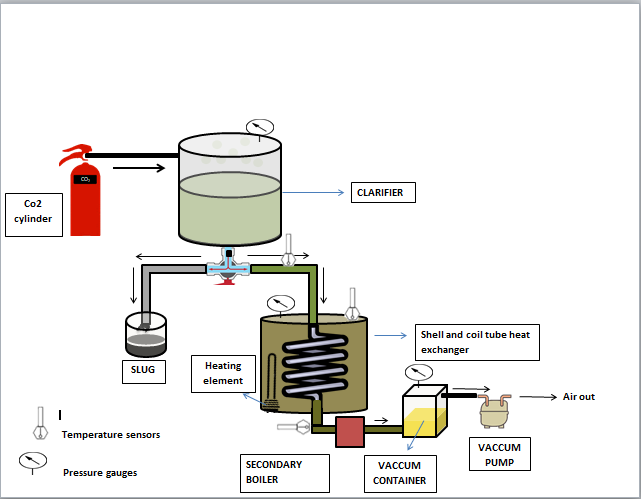

Process of sludge, mud, suspended and colloidal particles are removes by chemical compounds clarification occurs in a device called clarifier. Next is Evaporation In evaporation water is evaporated from the solution and we have used two evaporators/boilers in series the primary boiler makes our solution thick and after this thick solution is passed through secondary boiler which completely removes water content and make it thick slurry(paste) then we applied vacuum of -650mmhg which convert paste into brown crystal which are ready to use .this process of making crystal are called crystallization.

Socio-economic benefits

- It is beneficial for farmers of sugarcane that they can make their own sugar at homes.

- It is also related to the entrepreneurship for everyone, to start the business at low scales production industry.

- It operates in electricity and one person is enough to operate it easily.

Project methodology

- In this project firstly, clarification occurred in which we use milk of lime Ca(OH2) and carbon dioxide at different molarities of lime Ca(OH2) and weight of carbon dioxide in order to filter sugarcane solution.

- Secondly, we designed a shell and coil tube heat exchanger. In heat exchanger we designed its diameter, length , number of turns of coil and heat losses in this boiler. According to our required parameters and using heat and mass transfer equations.

- Further we designed a cold boiling setup in which we use compressor to make vacuum at -650mmhg in order to make brown sugar crystals.