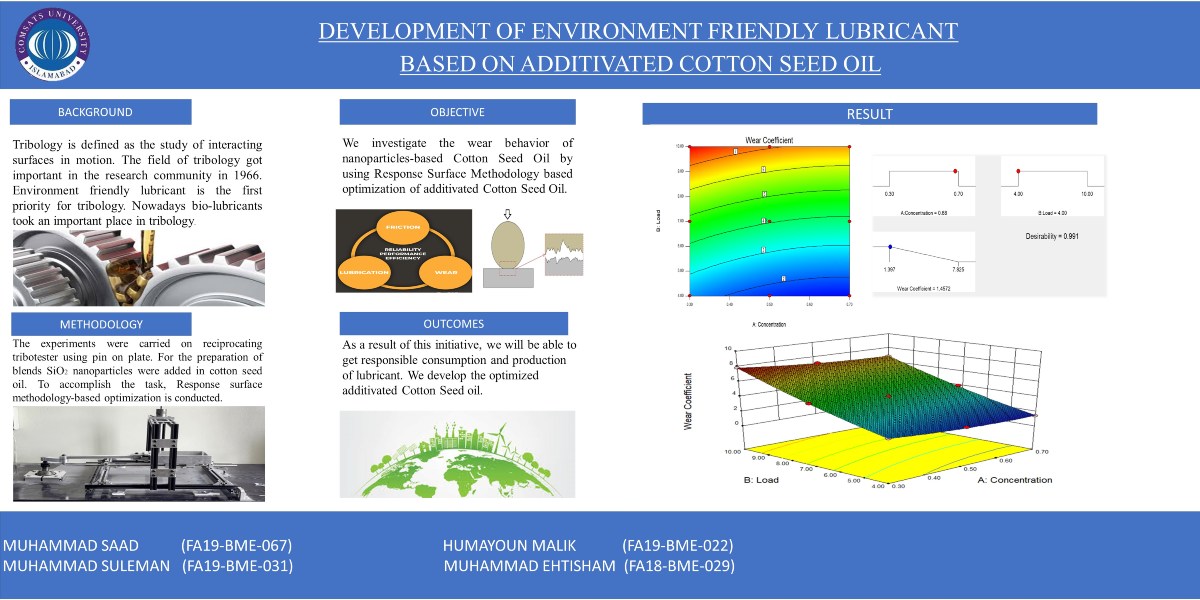

The aim of our final year project is to investigate the wear behaviour of nano particles based cotton seed oil by using Response surface methodology based optimization. By performing the experiments on pin on plate tribotester and putting results in RSM it is obtained that wear coefficient decreases by increasing the concentration of nano particles and wear coefficient increases by increasing the load.

Objectives

• To investigate the wear behavior of nanoparticles-based Cotton Seed Oil.

• Response Surface Methodology-based optimization of additivated Cotton Seed Oil

Socio-Economic Benefit

In our project we have two sustainable development goals affordable and clean energy (7) and life on land (15)

The use of green lubricants in tribology grows day by day for a clean environment. Environment-friendly lubricant is the first priority for tribology. In comparison to organic additives, nanoparticles are known for their thermal stability at high temperatures, making them a preferable option for lubricant additives. Because of the biodegradability, lubricity, high flash point, high viscosity index, and low evaporative losses, bio base oils can be used as an alternative to mineral-based lubrication oils.

Methodologies

To accomplish the task, Response surface methodology-based optimization is conducted. Response surface methodology that is based on mathematical and statistical technique used in experimental studies. In this study, RSM was used instead of conventional methods, which are time consuming and cannot account for variable interactions. Numeric factors for the experiments are (Load and Concentration of Nano particles). Maximum and minimum level of these factors are Load (4 and 7N) and Concentration of nanoparticles are (0.3and 0.7) used in central composite design.

For the preparation of blends SiO2 nanoparticles were added in cotton seed oil, the concentration of Nano particles were 0.3, 0.50 and 0.70 % by weight. Blends formation was done by the help of magnetic stirrer at 650 rpm and the temperature was 60 °C.

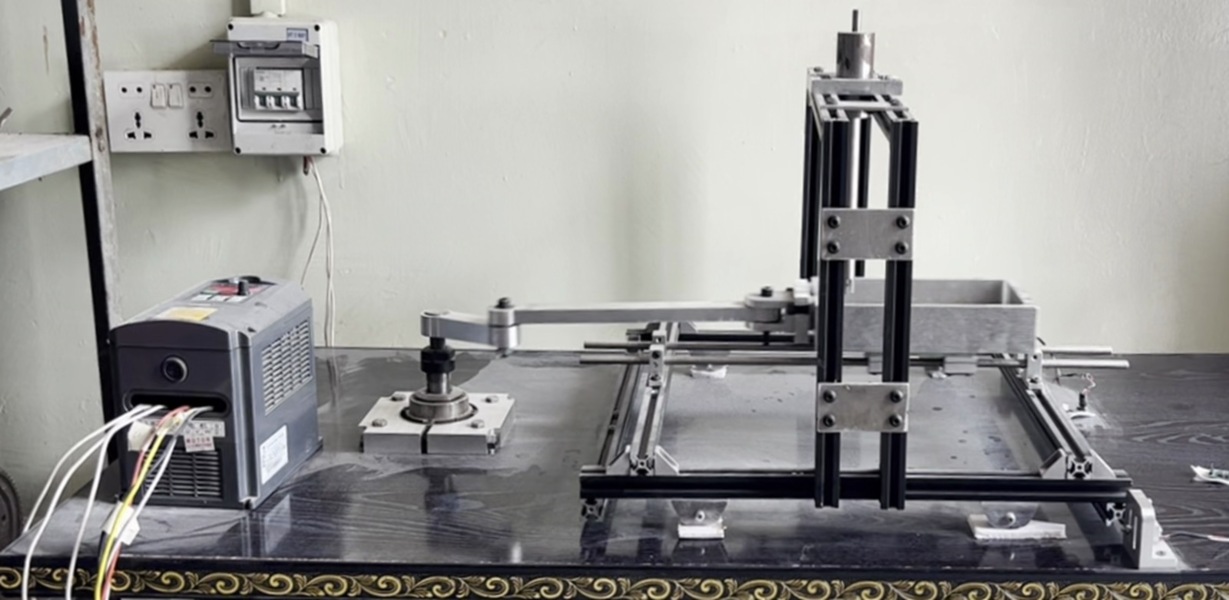

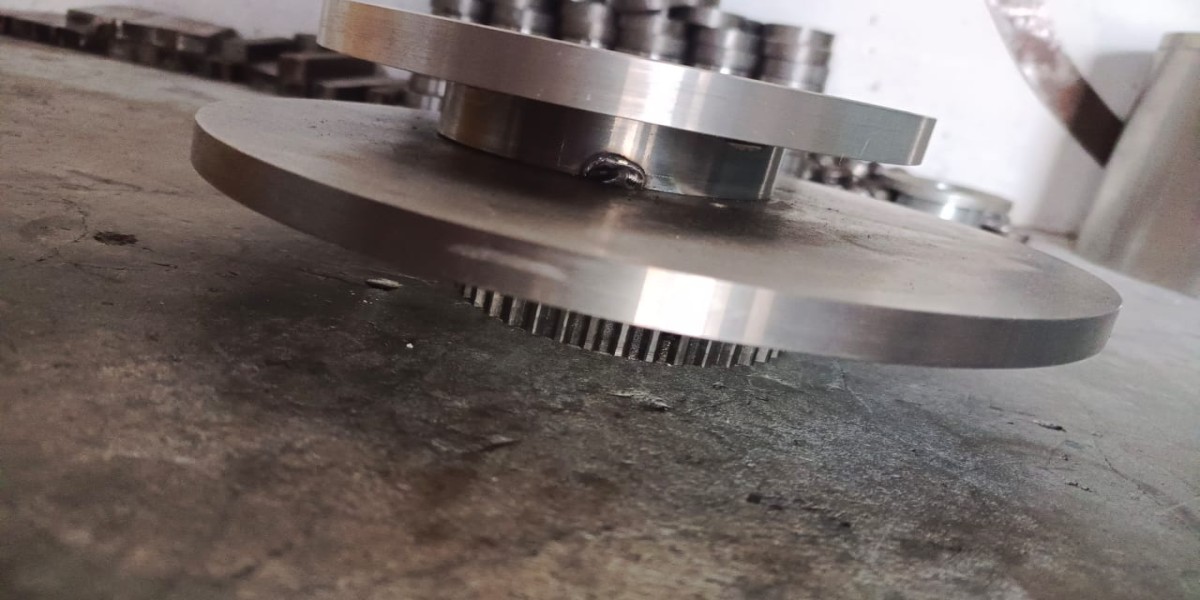

The experiments were carried on reciprocating tribotester using pin and plates and wear coefficient was calculated using Archard’s equation.

Outcome

Development of optimized additivated Cotton Seed Oil.

Development of Environment Friendly Lubricant.

Development of Cost Effective Lubricant