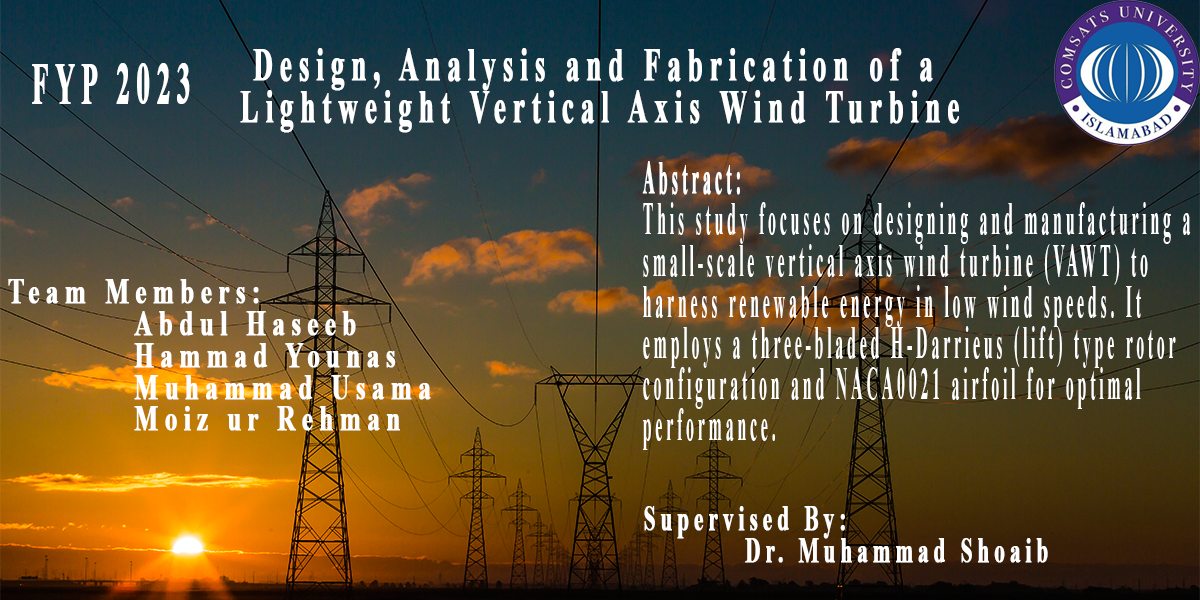

Objectives

The objective of this project is to carry out a detailed design, fabrication, analysis and experimental testing of a lightweight vertical axis wind turbine for sustainable small scale electric power applications.

Socio-Economic Benefit

SDGs related to our project are

SDG 7. Affordable and clean energy.

SDG 8. Decent work and economic growth.

SDG 12. Responsible Consumption and Production

SDG 13. Climate Action.

Methodologies

Mathematical Modelling:

Based on different formulas and equation we finalize our deign parameters.

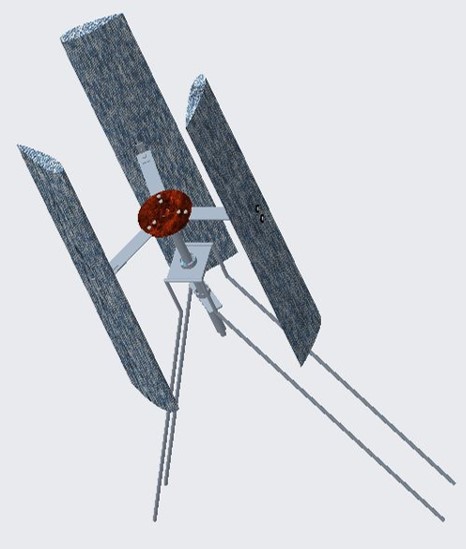

Cad Modeling :

After analytical design we design our 3D CAD model on Creo for our better understanding and for the easiness in manufacturing

FEA Analysis:

Analysis on NACA 0021 aero foil was done to find the angle of attack on which maximum lift is producing.

Manufacturing

First we manufacture our blade with hot wire cutting then cover it with glass fibre

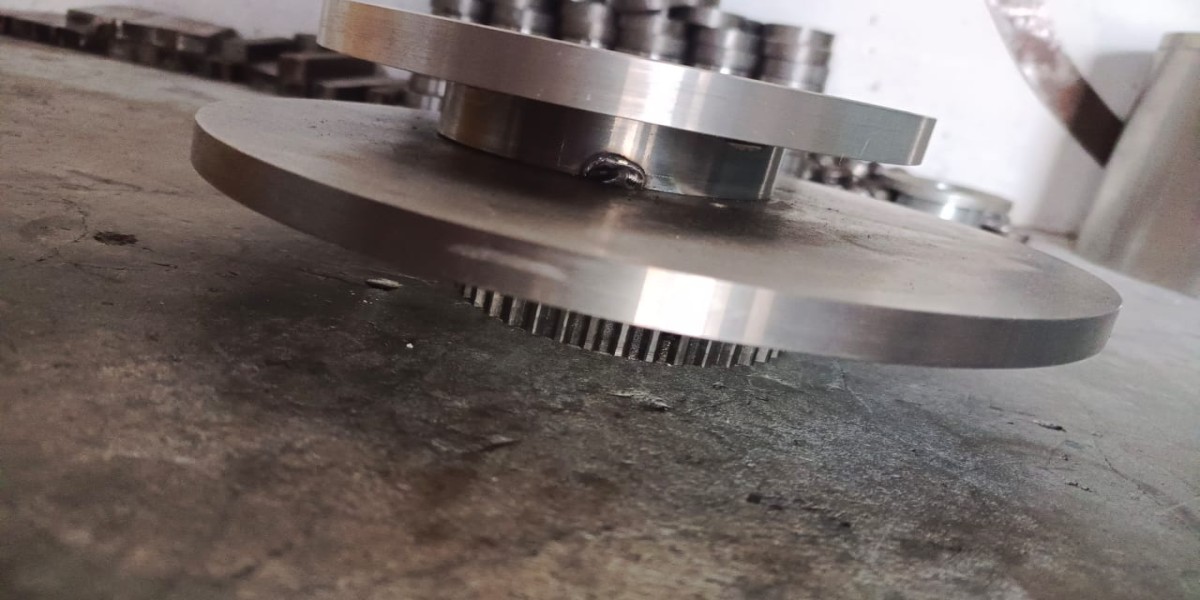

In the second step we manufacture the stand( with Cutting & welding) and make bearing housing on stand.On upper side of stand we use thrust bearing and on lower side we use ball bearing.

Also make an arrangement for generator/Motor on one right/left side of stand to rotate with fkywheel.

Testing:

For testing of turbine on our rated wind speed and different angle of attacks we use artificial air from wind tunnel apparatus and noted the power out.

Outcome

Analytical calculations for a design of a 100-watt wind turbine.

Detailed CAD modeling and engineering drawings of VAWT.

Finite element analysis of aerofoil to find angle of attack on which maximum lift can be achieved

Materials purchase and manufacturing of each constituent components of VAWT.

Final assembly of the VAWT and the mountings.

Experimental testing.