Objectives

The "Design and Fabrication of High Energy Ball Mill for Nanoparticles Synthesis" project aims to develop an innovative milling system capable of producing nanoparticles with enhanced properties. The project addresses Pakistan's current reliance on imported nanoparticles in the metallurgy industry by providing a local solution for nanoparticle synthesis.

The specific objectives include designing and fabricating a high energy ball mill that can efficiently grind metal powders into fine grains ranging from 50 nm to 100 nm. The project aims to optimize milling parameters such as rotational speed, milling time, and ball-to-powder ratio to achieve precise control over particle size, distribution, and morphology.

Characterization techniques like SEM, TEM, XRD, and FTIR will be employed to evaluate the synthesized nanoparticles' properties, including particle size, morphology, crystal structure, and chemical composition. The project also seeks to assess the nanoparticles' potential applications in cosmetics, herbs, 3D metal printing, antibacterial agents, pharmaceuticals, and surface coating materials.

In addition to scientific objectives, the project will conduct a business feasibility analysis to explore the commercial viability of selling the synthesized nanoparticles in the open market. Market research, cost analysis, and competitive assessment will be performed to identify potential customers, determine market demand, and develop pricing strategies. A comprehensive business plan will be created to outline revenue streams, marketing strategies, and scalability.

The project aims to disseminate knowledge through publications, presentations, and engagement with relevant industries and stakeholders. Documentation, including design drawings, experimental protocols, and characterization results, will be prepared for future reference and project replicability.

The primary objective is to reduce particle size and sell the synthesized nanoparticles in the open market for business purposes. The project targets the local metallurgy industry's need for locally produced nanoparticles, fostering self-sufficiency and technological advancement. By producing high-quality nanoparticles, the project aims to contribute to various fields such as cosmetics, pharmaceuticals, surface coating materials, and create business opportunities in the nanotechnology sector.

Socio-Economic Benefit

The "Design and Fabrication of High Energy Ball Mill for Nanoparticles Synthesis" project brings significant socio-economic benefits. By producing locally synthesized nanoparticles, it reduces dependency on imports, stimulates economic growth, and fosters technological advancement.

Economic Benefits:

Reduced Dependency: The project provides a local solution, reducing reliance on imported nanoparticles and promoting self-sufficiency in the metallurgy industry.

Job Creation: Establishing a nanoparticle synthesis facility creates employment opportunities for researchers, technicians, operators, and support staff.

Business Opportunities: Local nanoparticle production opens new markets in cosmetics, pharmaceuticals, 3D printing, and surface coatings, fostering entrepreneurship and economic development.

Technological Advancement:

Research and Development: The project advances nanoparticle synthesis, milling techniques, and characterization methods, contributing to scientific knowledge and innovation.

Technology Transfer: Findings and expertise can be shared with other institutions and industries, encouraging collaboration and fostering technological growth.

Social and Environmental Impact:

Accessible Nano-products: Locally produced nanoparticles enhance accessibility and affordability in industries, benefiting consumers and promoting sector growth.

Health and Safety: The project prioritizes safety protocols, ensuring the well-being of workers, researchers, and the environment.

Sustainable Practices: Local production reduces carbon emissions associated with imports, promoting sustainable manufacturing processes.

Knowledge Dissemination and Collaboration:

Knowledge Sharing: Project findings are shared through publications, presentations, and engagement, encouraging further research and best practice adoption.

Collaboration Opportunities: The project facilitates collaborations between academia, industry, and government, enhancing innovation and effectiveness.

In summary, the "Design and Fabrication of High Energy Ball Mill for Nanoparticles Synthesis" project reduces dependency, creates jobs, stimulates the economy, and drives technological advancement. It enhances accessibility, promotes sustainability, and encourages knowledge dissemination and collaboration, contributing to socio-economic development.

Methodologies

The project methodology for the "Design and Fabrication of High Energy Ball Mill for Nanoparticles Synthesis" involves a systematic approach to achieve the desired objectives. The following steps outline the key aspects of the project:

Research and Literature Review:

• Conduct an extensive literature review on high energy ball milling, nanoparticle synthesis methods, and relevant technologies.

• Identify the best practices, equipment, and materials used in similar projects.

• Analyze the properties and applications of nanoparticles in various industries.

Experimental Setup:

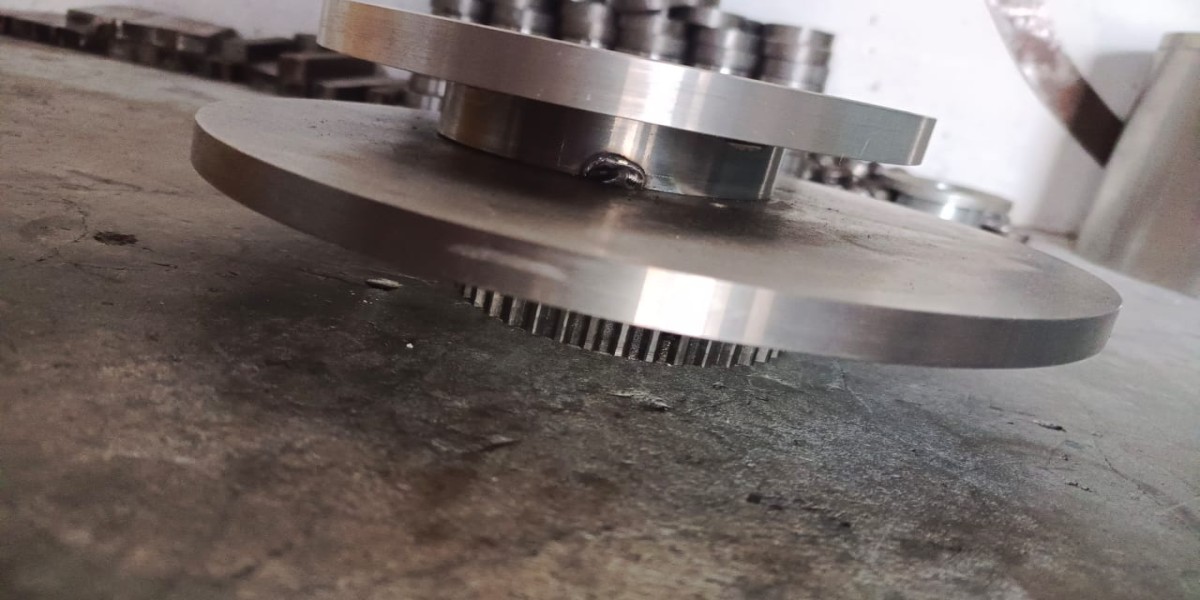

• Design and fabricate a high energy ball mill system capable of grinding metal powders into fine nanoparticles.

• Select appropriate stainless-steel balls and optimize their rotational speed for effective crushing of metals.

• Implement safety measures and protocols to ensure a secure working environment.

Nanoparticle Synthesis:

• Utilize the high energy ball mill to crush metal powders and synthesize nanoparticles.

• Begin with metals such as aluminum and progress to other metals like tungsten and titanium.

• Control the milling parameters including ball size, milling time, and chamber temperature to achieve desired particle size and properties.

Characterization and Analysis:

• Perform thorough characterization of the synthesized nanoparticles using techniques such as microscopy, spectroscopy, and particle size analysis.

• Evaluate the chemical composition, crystallinity, morphology, and size distribution of the nanoparticles.

• Compare the obtained results with established standards and literature data to ensure quality and consistency.

Material Testing and Evaluation:

• Compress the green dyes/billets of the synthesized nanoparticles using high-pressure machines.

• Sinter the compressed materials in a furnace at a temperature of 1500 degrees Celsius to achieve solidification and bonding.

• Conduct mechanical testing to assess the strength, hardness, and other mechanical properties of the sintered material.

Business Development and Market Implementation:

• Verify the suitability of the synthesized nanoparticles for target industries, including cosmetics, 3D metal printing, and powder metallurgy.

• Establish partnerships and collaborations with potential customers, industries, and research institutions.

• Develop a business plan for the production and commercialization of the synthesized nanoparticles.

Documentation and Reporting:

• Maintain detailed records of experimental procedures, observations, and results.

• Prepare comprehensive reports and presentations summarizing the project methodology, findings, and recommendations.

• Disseminate the project outcomes through scientific publications, conferences, and knowledge-sharing platforms.

Throughout the project, regular monitoring, data analysis, and adjustments will be made to ensure the successful implementation of the methodology and the achievement of the project's objectives.

Outcome

The project outcomes for the "Design and Fabrication of High Energy Ball Mill for Nanoparticles Synthesis" are as follows:

• Development of a high energy ball mill system for grinding metal powders into fine nanoparticles, achieving particle sizes of 50 nm to 100 nm.

• Successful synthesis of nanoparticles from various metals, tailored for specific applications through control of milling parameters.

• Comprehensive characterization and analysis of nanoparticles to ensure quality and consistency.

• Testing and evaluation of sintered materials for strength and mechanical properties.

• Business development and market implementation, providing locally produced nanoparticles to reduce costs and stimulate domestic industries.

• Socio-economic impact, including the expansion of localized cottage industries, profit generation, and economic growth through affordable raw materials.

These outcomes will advance nanoparticle synthesis techniques, provide locally produced nanoparticles for Pakistan's metallurgy industry, and foster economic growth and innovation.