The goal of the project "Design, Fabrication, and Analysis of Artificial Bio Implant" is to create a joint implant system that overcomes the drawbacks of current implants. The project intends to provide a cost-effective, long-lasting, and biocompatible solution for people with joint-related injuries and disabilities by integrating cutting-edge materials, engineering concepts, and biotechnology. Extensive research, conceptual design, material selection, prototyping, rigorous testing and analysis, iterative refinement, manufacturing process optimisation, and assuring regulatory compliance are all part of the project operations. By enhancing mobility, reducing discomfort, and enhancing functionality, the project aims to improve patients' quality of life. The project's results will benefit local economies, promote knowledge sharing and capacity building, and advance medical technological expertise, all of which will benefit society more broadly.

Objectives

• To Geometrically analyze the hip joint implant.

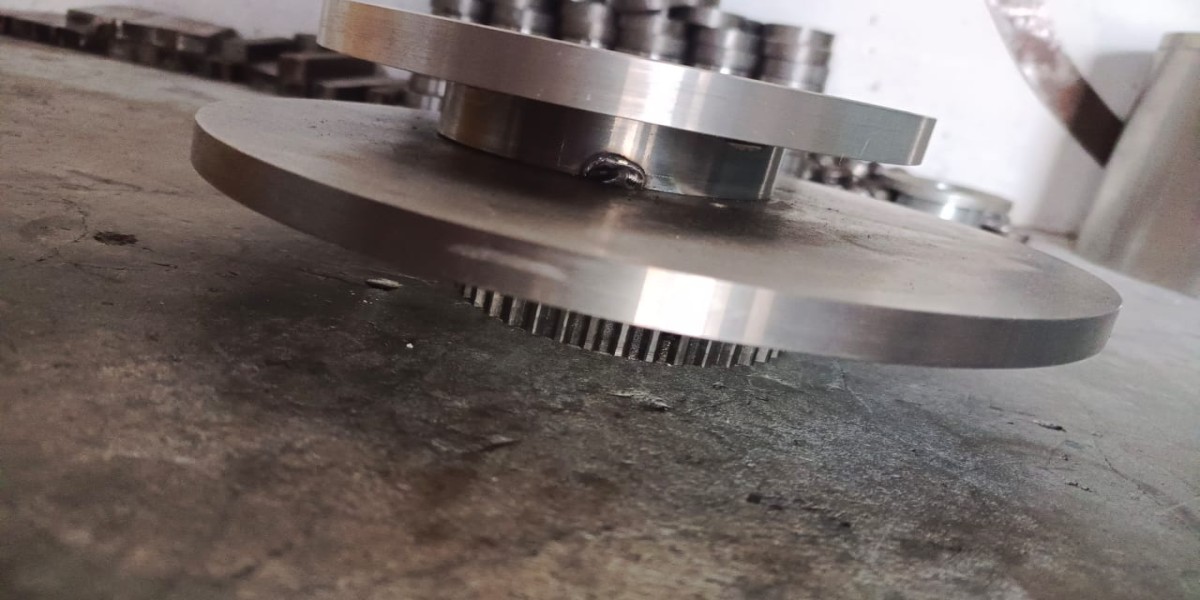

• Structural and surface design by the combination of rapid manufacturing and traditional machining.

• Prototype development to asses feasibility of hip joint using modern manufacturing.

• To investigate structural strength and conduct structural stress analysis.

Socio-Economic Benefit

For individuals, communities, and healthcare systems, the project has major socioeconomic advantages. First off, by offering a cost-effective, long-lasting, and biocompatible solution, it enhances the quality of life for people who have joint-related injuries and disabilities. As a result, they are able to regain mobility, manage their pain, and perform everyday tasks in greater comfort, which improves their general wellbeing and productivity. Second, by providing an alternative to pricey standard joint replacement surgeries, the project promotes cost-effectiveness. The artificial bio-implant's affordability eases the financial load on patients and healthcare systems and makes it available to a wider range of people. In turn, this results in lower healthcare expenses and better resource use. By generating employment possibilities and encouraging entrepreneurship in the medical technology industry, the project also promotes local economic growth. The manufacture and distribution of the synthetic bio-implants create income and support the regional economy. It increases knowledge of the design, manufacture, and analysis of medical implants, resulting in improvements to the healthcare system. This benefits the project itself as well as the training of a trained personnel and the advancement of technology in the healthcare industry. Improved quality of life, cost effectiveness, local economic growth, lower healthcare expenses, and knowledge transfer are just a few of the project's overall socio-economic benefits, all of which have a positive influence on people, communities, and healthcare systems.

Methodologies

We conducted an extensive review of 43 existing research, scientific papers, and medical literature related to joint implant technologies, materials, and fabrication techniques. Based on the literature review findings, we established a conceptual design for the artificial bio-implant. We evaluated various materials such as Ti-6al-4V, SS316, SS314L, Platinum, for the implant components. We used CAD software to develop a detailed 3D model of the implant, and created 16 prototypes using additive manufacturing techniques.

We developed a scalable and cost-effective manufacturing process for mass production. We documented all design specifications, fabrication procedures, and analysis findings.

Outcome

The project's results are anticipated to have a substantial and transformative impact on the field of joint replacement surgery. First and foremost, the initiative seeks to produce a cutting-edge artificial bio-implant that goes beyond the constraints of conventional implants. Through improved mobility, less discomfort, and increased usefulness, this result will give those with joint-related injuries and disabilities a higher quality of life.

Second, the project aims to produce the artificial bio-implant at an affordable price. The research intends to reduce the implant's overall cost and make it more affordable for a larger population by streamlining the production procedure and choosing the right materials.

Additionally, the project hopes to enhance knowledge and proficiency in the area of medical technology. The research's results will generate insightful knowledge and breakthroughs in joint implant technology, which will be advantageous to both the project and the larger medical community.

The project also intends to lay a solid foundation for ongoing study and advancement in the area. The project results will serve as a valuable resource for future endeavours by documenting the design specifications, fabrication techniques, and testing outcomes, encouraging continual development and innovation.