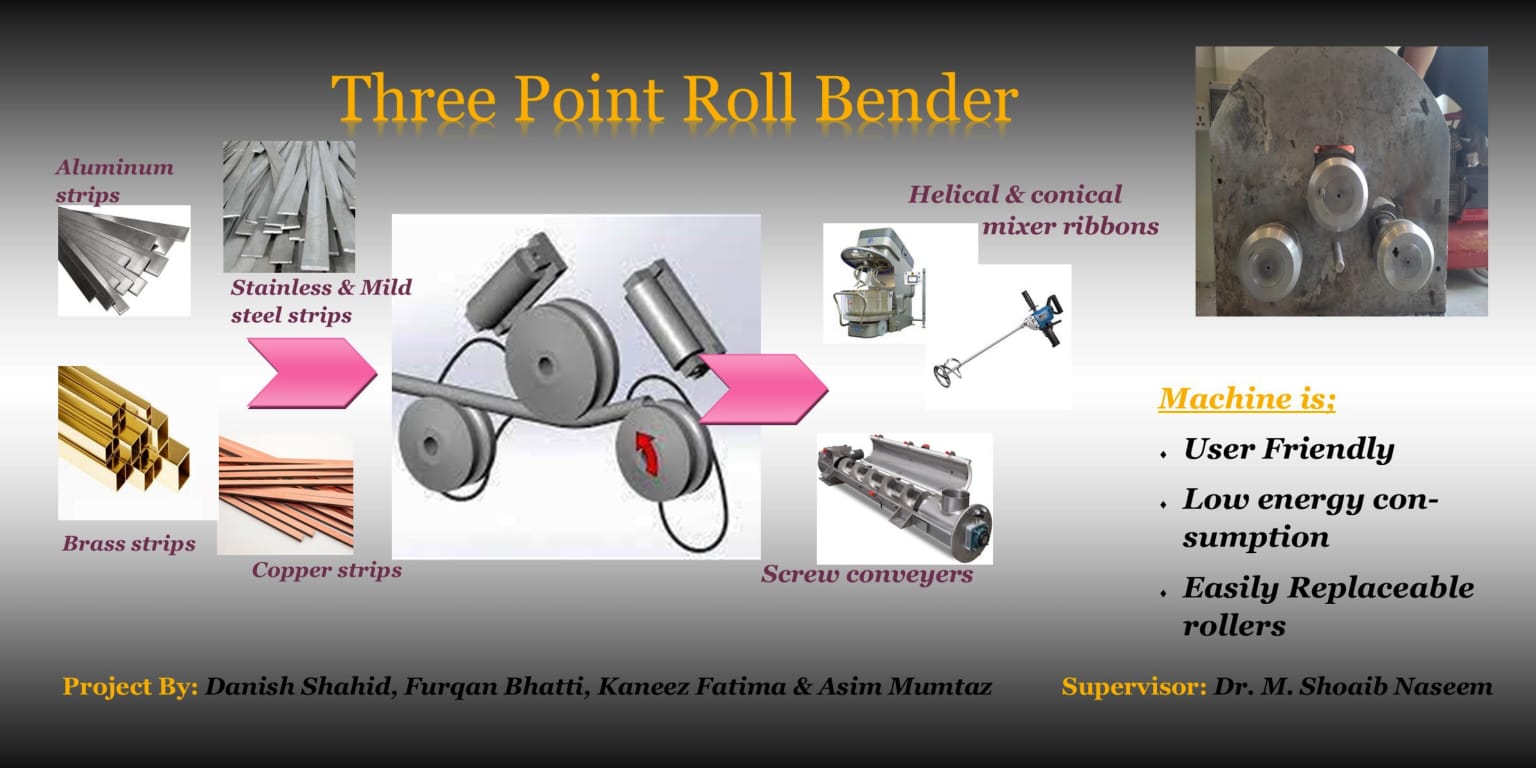

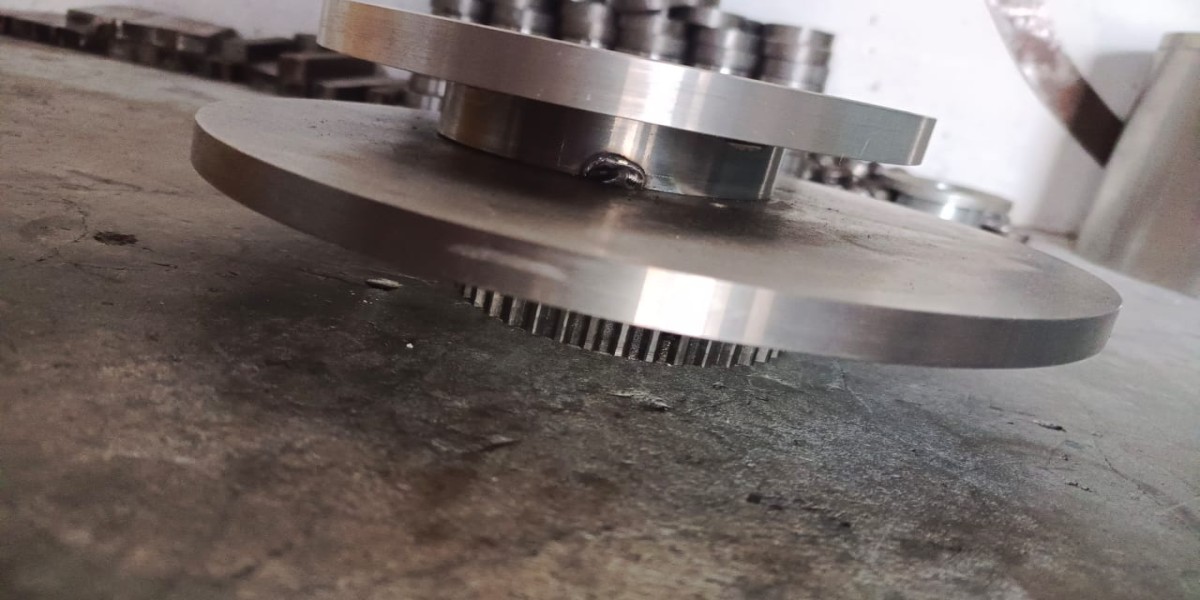

In Pakistan industrial mixers are imported due to a lack of precision bending machines. Local manufacturers are limited to mild steel ribbons and conical ribbons can not be made by conventional procedures. We have developed a rolling machine Capable of manufacturing a variable pitch ribbon suitable for multistage mixing. User-friendly and compliant to market needs requiring low power input. Changing rollers will enable the machine to bend rods, round/profile pipes, and emboss designs while bending requiring minimum maintenance.

Objectives

As no such machine is available in Pakistan we aim to design and fabricate a bench top roll bending machine that can effectively produce straight and conical mixer ribbons along with a variety of other products that are used in our daily lives.There is no such machine in Pakistan that can effectively produce mixer ribbons and perform roll bending operation accurately.We are aiming to introduce a high quality machine that is affordable to all small scale manufacturers of Pakistan.This is also help people to set up their own businesses contributing to the economy of Pakistan.

Socio-Economic Benefit

This machine will benefit individuals as well as the state.

- Reducing imports

- Increasing exports

- Creating job opportunities

- Conical and multistage mixers have a big export potential

- Upgrading local industry by reducing electricity consumption

- Availability of these particular mixers at a cheap cost will enable local soap, shampoo, detergent, adhesive, and foam manufacturers to produce export-quality products. Cutting our import bills.

Methodologies

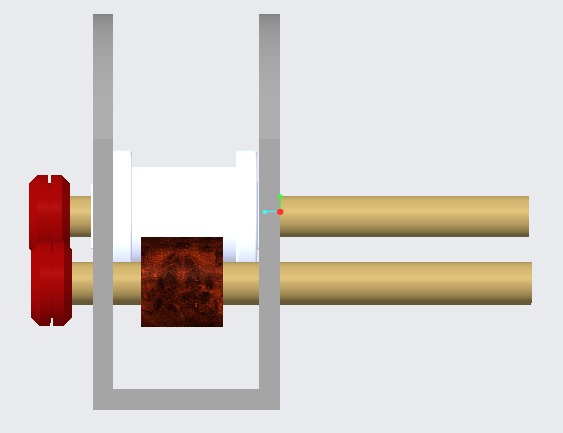

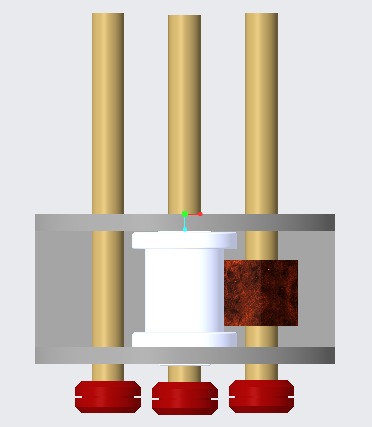

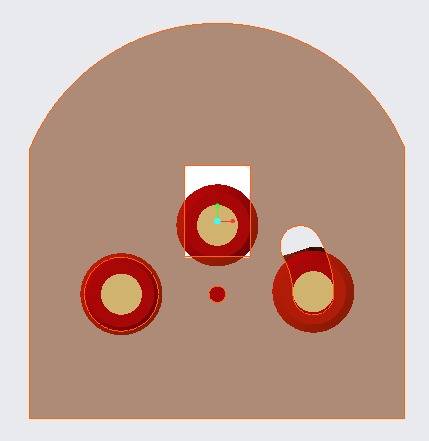

This project is using the concept of rolling to achieve our objective which is cold-rolled ribbon. The bottom right roller will move upward in an arc reaching the top roller which will assist to reduce the chord length and achieve the biggest possible radi consequently reducing the material wastage at the ends. For this, we have developed a mechanism with hydraulic jacks that helps us to consume negligible energy.

Outcome

It can be used to manufacture

1:Mixer ribbons

2:Plodders for injection molding and soap making

3:Screw conveyors/ Augers

4:Steel furniture

5:Staircase railing

6:Bike rims

7:Architectural pieces

8:Track rails for stairlifts