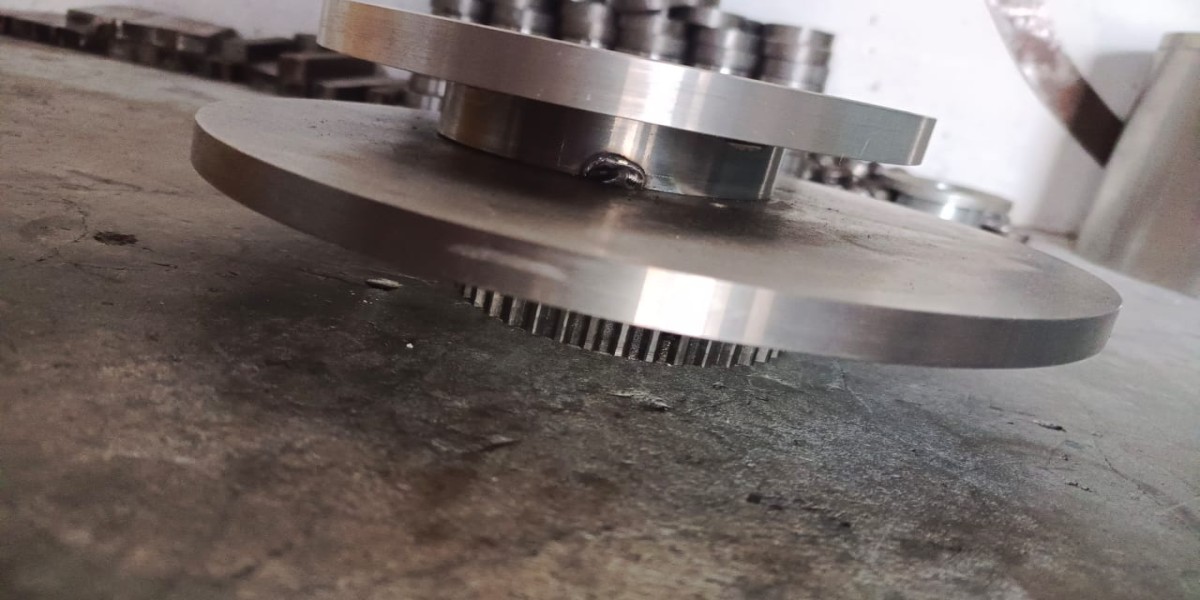

Hammermill as the name suggests reduces the size of the fed material through repeated hammering. Shearing, friction, vibration and collisions between the particles and the wall of the grinding chamber also aid the grinding. It consists of a series of hammers hinged on a central shaft, which is rotating at high speed inside a chamber. A sieve is attached so that the particles that have achieved the required size can leave the chamber.The material used for the components is mild steel. The control factors, sieve size of 40 mesh, Rotar speed, Fill level of 15% of the grinding chamber and clearance between the tip of the hammer and the anvil (the chamber wall) of 0.5 mm, are set to optimize the process the process according to the required particle size.

Objectives

The objective of this “Rotary Hammer Mill” is to play a vital role in the grinding industry in Pakistan by developing a portable Hammer Mill that is cheap, easy to carry and maintain compared to the conventional grinders. It is effective at grinding various domestic and industrial materials into fine 40 mesh size particles.

Currently, the Pakistani industry relies heavily on stone wheel grinders for wheat and other grains, and large jaw crushers for mineral ores. Both of these machines are highly energy-intensive and require significant amounts of electricity or fuel to run. Additionally, the stone wheels used for edible grains are imported, further increasing costs.

The aim is to create a unique three-layered swinging hammer design that can be manufactured locally and consumes significantly less energy compared to the grinders commonly used in Pakistan. We are committed to introducing a machine that requires minimal maintenance and is more affordable than existing alternatives, helping Pakistani manufacturers and users to save both cost and time.

Furthermore, the small-sized mill in the Pakistani market that can grind glass scrap into fine powder. Glass scrap is widely available in the country, and powdered glass can be used to make abrasive powders and pastes, new glass products at a lower cost, and can even be used in cement making and electronics. The Hammer Mill not only cuts import costs but also helps get rid of hazardous glass waste. Abrasive compounds are extensively used in Marble, Automotive, Aviation, and Mechanical industries and have a significant export potential.

The high-quality yet affordable Hammer Mill can also be used domestically or at a small scale to grind wheat, barley, herbs, and spices, providing opportunities for small-scale/cottage industries to thrive and bolstering Pakistan's economy. It is a sustainable and efficient solution to Pakistan's grinding needs while contributing to the country's economic growth.

Socio-Economic Benefit

Hammer mills have numerous advantages over conventional grinding machines. They are more efficient, faster, and require minimal maintenance. Hammer mill can grind the feed material in a continuous process in one go rather than multi-stage grinding. Additionally, the particle size can be easily adjusted by replacing the sieve with another mesh size. It runs on a single phase 1 horsepower motor.

By introducing locally manufactured hammer mills, Pakistan can reduce its import bills, reduce the load on the national grid, and promote local manufacturing. Currently, stone wheel and blade grinders are imported into Pakistan, which is a significant expense for the country. By using locally available resources to manufacture hammer mills, the country can reduce its dependence on imports and encourage local manufacturing.

The durability of these mills is higher than other mills available in the market, making them a more cost-effective and long-lasting solution. The process industry has a huge demand for hammer mills as they are used for grinding a variety of materials, from coal in power plants to raw materials for medicine and cosmetics. By introducing locally manufactured hammer mills, Pakistan can meet the demand for such machines in the industry and create opportunities for its people to work in the manufacturing sector.

Methodologies

This innovative Rotary Hammer Mill design has been meticulously developed through a rigorous research process, encompassing an in-depth exploration of various existing Hammer Mill designs. Building upon this knowledge, we furthered our efforts by employing mathematical modeling techniques and creating a comprehensive CAD model. To ensure the design's viability and effectiveness, we conducted simulations to simulate real-world scenarios and assess its performance.

Simultaneously, we initiated the development phase, translating the conceptual design into a tangible and functional prototype. Throughout the development process, we paid meticulous attention to detail, ensuring that every component and mechanism aligns seamlessly to deliver optimal performance and efficiency.

To validate the design and assess its capabilities, we carried out a series of rigorous test trials. These trials involved subjecting the Rotary Hammer Mill to various operating conditions, feed materials, and particle size requirements. By meticulously analyzing the results and comparing them to our performance targets, we were able to fine-tune the design, optimize its functionality, and ensure its suitability for a wide range of applications.

The combination of thorough research, mathematical modeling, CAD simulations, and rigorous test trials has culminated in the creation of a robust and reliable Rotary Hammer Mill design. We are confident that this innovative solution will revolutionize the industry by providing enhanced efficiency, reduced operational costs, and improved grinding performance.

Outcome

The products of hammermill include ground glass, ceramics and mineral rocks. The ground glass and ceramics are used in recycling, new product development, electronic components, water resistant cement, prosthesis and abrasives.