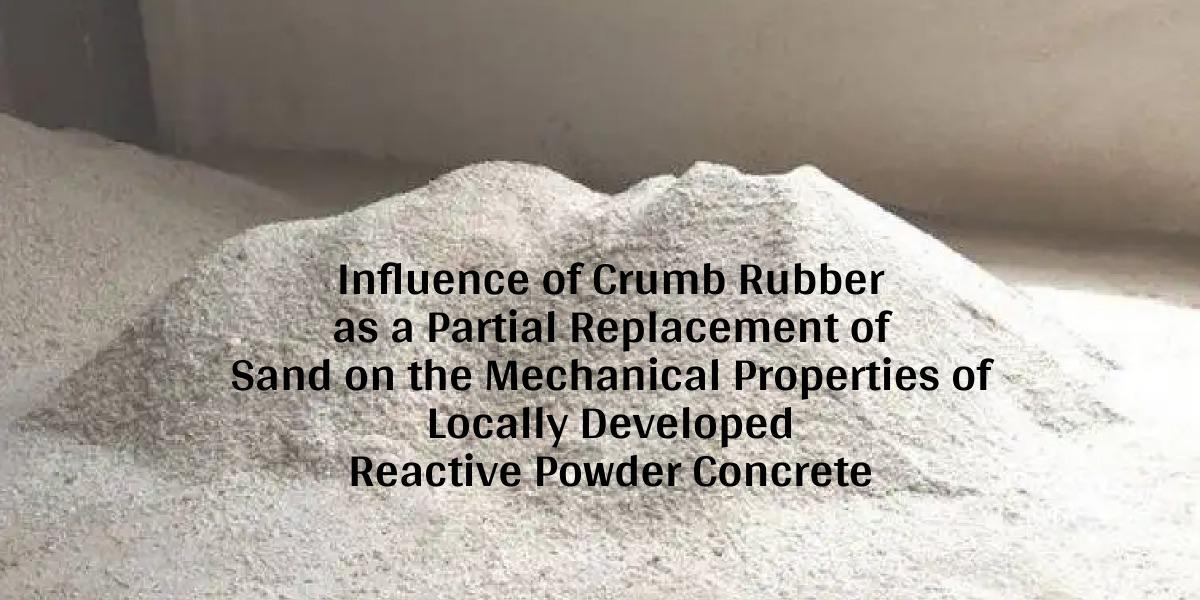

This project investigates the use of crumb rubber, derived from recycled waste tires, as a partial replacement for natural sand in the production of Reactive Powder Concrete (RPC). The aim is to assess how varying proportions of crumb rubber affect the mechanical properties such as compressive, flexural, and tensile strength of RPC developed using locally available materials. The study promotes sustainable construction practices by incorporating eco-friendly waste materials while maintaining the structural performance of high-strength concrete.

Objectives

To evaluate the effect of varying rubber content as a sand replacement on the compressive strength of reactive powder concrete.

To assess the effect of crumb rubber as partial sand replacement on the flexural strength and ductility of locally developed Reactive Powder Concrete, aiming to enhance strain capacity and reduce brittleness.

To analyze the influence of rubber content on the microstructural characteristics of reactive powder concrete using scanning electron microscopy (SEM).

To optimize the proportion of rubber as a sand replacement to achieve an optimal balance between mechanical strength and performance in reactive powder concrete by using AI.

Socio-Economic Benefit

The incorporation of crumb rubber as a partial replacement for sand in Reactive Powder Concrete (RPC) offers several important socio-economic benefits, contributing to both environmental sustainability and economic efficiency:

1. Environmental Sustainability

Waste Tire Management: Helps reduce the large volumes of scrap tires that typically end up in landfills or are burned, thus minimizing environmental pollution and health hazards.

Natural Resource Conservation: Reduces the demand for natural river sand, preserving ecosystems and decreasing environmental degradation caused by sand mining.

2. Cost-Effectiveness

Material Cost Reduction: Crumb rubber is a low-cost material compared to high-quality quartz sand used in RPC. Partial replacement helps lower the overall material cost.

Waste-to-Resource Conversion: Turns waste tires into valuable construction materials, promoting a circular economy and reducing disposal costs for municipalities.

3. Employment and Local Economy

Job Creation: Promotes the growth of local recycling industries, leading to job opportunities in waste tire collection, processing, and rubber granulation.

Support for Local Suppliers: Encourages the use of locally available materials (cement, sand, rubber), supporting regional industries and reducing transportation costs.

4. Innovation in Construction

Affordable Sustainable Materials: Offers an alternative for producing high-performance concrete at a lower environmental and financial cost, making advanced construction technologies more accessible.

Potential in Infrastructure Projects: Can be used in non-structural and low-load applications (e.g., pavements, precast blocks), making infrastructure development more sustainable and cost-efficient.

5. Public Health and Safety

Reduction in Air and Soil Pollution: Mitigates the harmful effects of tire dumping and open burning, which release toxic gases and chemicals into the environment.

Cleaner Urban Environments: Promotes cleaner cities by reducing visible tire waste and related vector-borne health risks.

This project aligns with global goals such as the United Nations Sustainable Development Goals (SDGs), especially:

SDG 9: Industry, Innovation and Infrastructure

SDG 11: Sustainable Cities and Communities

SDG 12: Responsible Consumption and Production

SDG 13: Climate Action

Methodologies

Material Selection

Cement, Sand, Silica Fume, Steel Fibers, Super Plasticizer, Crumb Rubber

Mix Proportions

According to mix design table

Preparation of Reactive Powder Concrete

Batching

Mixing

Incorporation of Steel Fibers

Casting of Specimens

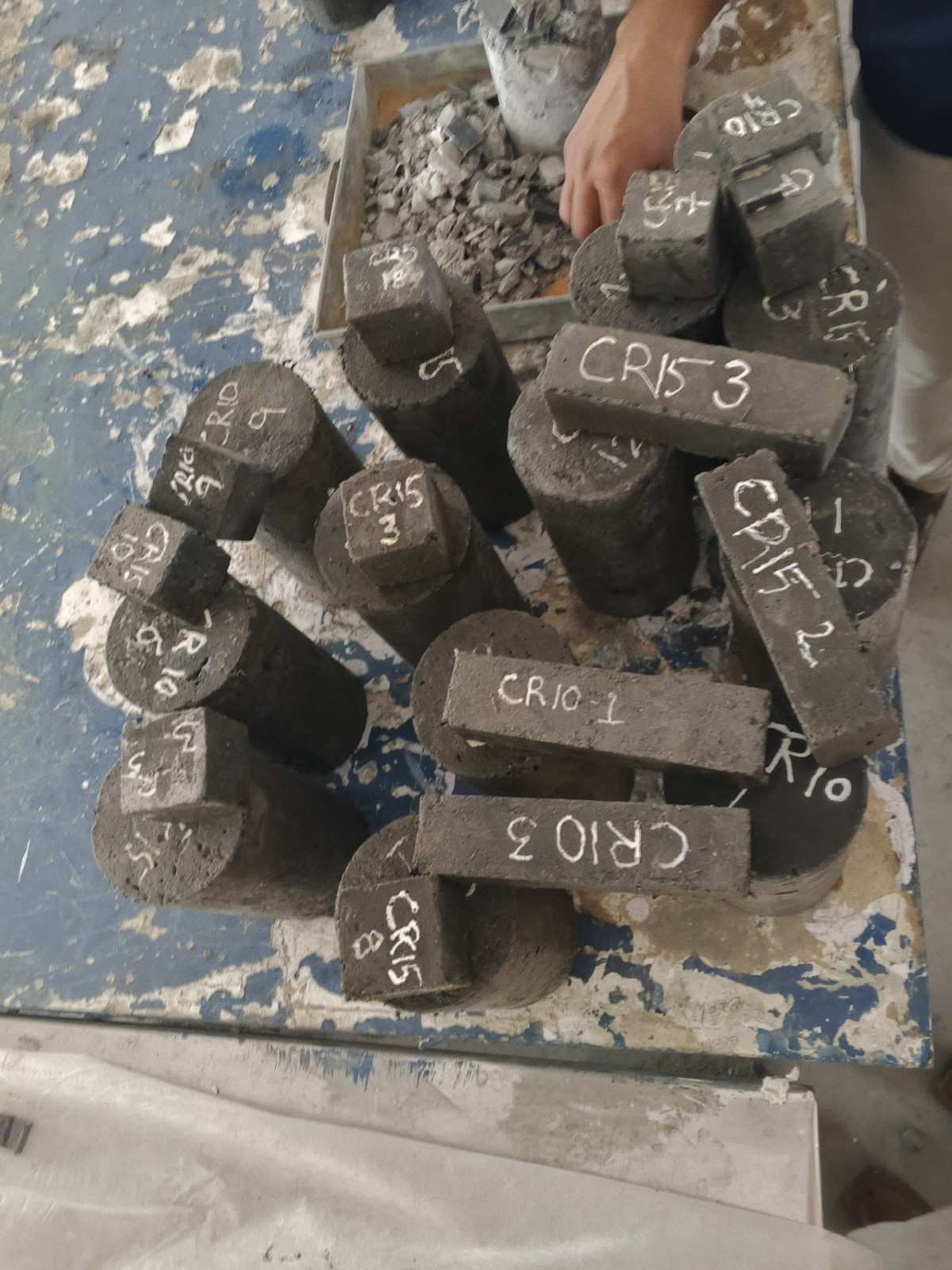

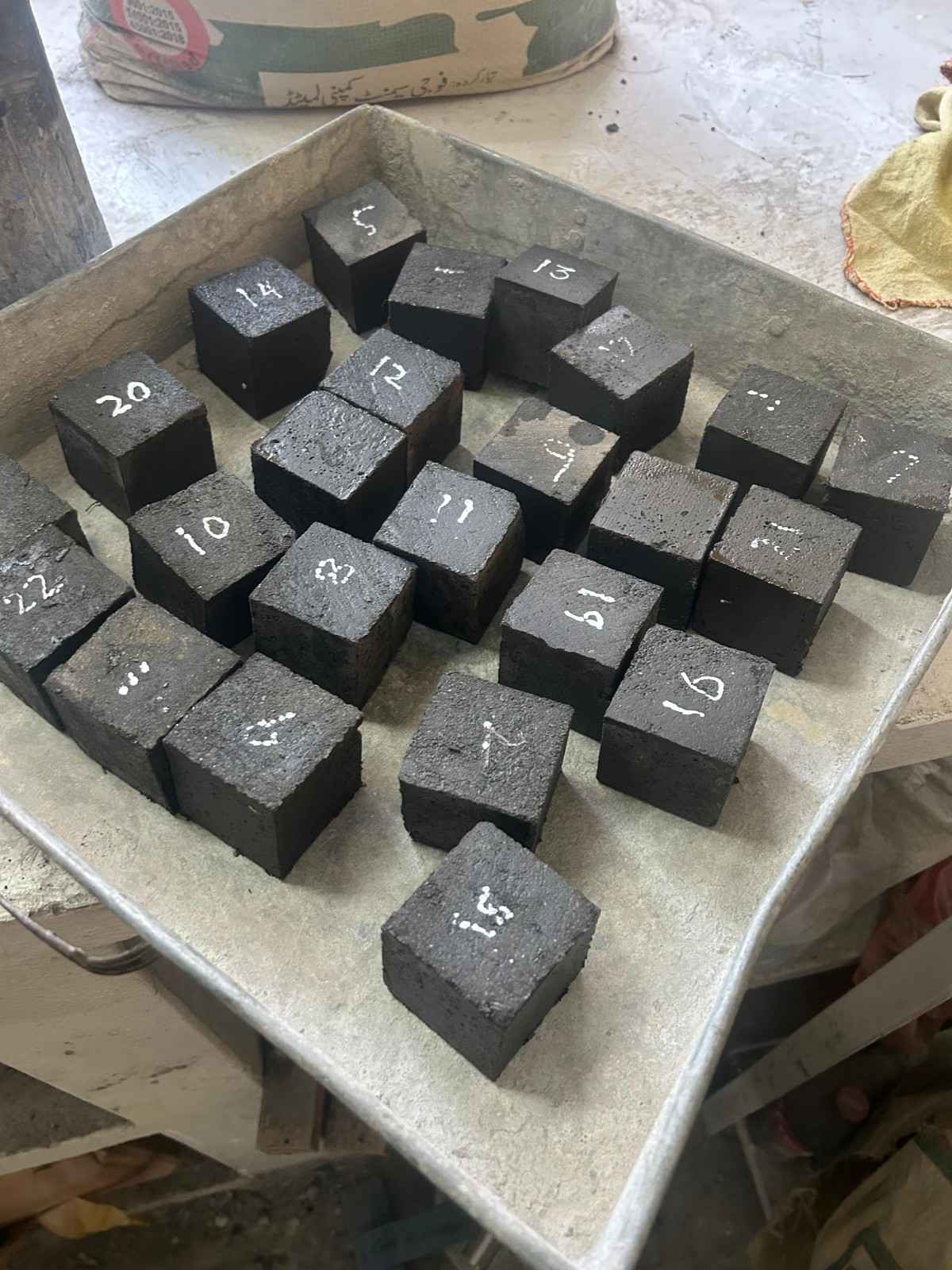

Prepare Concrete cubes for compressive strength test, prisms for flexural strength and Cylinders for split tensile strength tests

Curing of Specimens

After demolding cure the specimens in a water tank for 7, 14 and 28 days

Testing of Specimens

Compressive Strength Test

Flexural Strength Test

Split Tensile Strength Test

Data Analysis and Interpretation

Compare the results of control mix with crumb rubber mixes

Concluding using Artificial Intelligence Techniques

Outcome

Strength Reduction with Rubber:

Replacing sand with crumb rubber consistently reduces compressive, tensile, and flexural strength, with greater reductions at higher replacement levels.

Optimal at 5% Replacement:

A 5% rubber replacement offers a good balance between strength (~55 MPa compressive, ~20 MPa tensile, ~47 MPa flexural) and sustainability.

Unsuitable Beyond 15%:

At 15% replacement, strength drops significantly, making the mix unsuitable for structural applications without reinforcement.

Improved Ductility Potential:

Despite strength loss, rubber may improve ductility and crack resistance, especially when combined with steel fibers.