Objectives

The aim of this project is to evaluate the use of plastic waste as a modifier in asphalt mixtures to enhance road performance, promote sustainability, and offer a cost-effective solution for road construction in Pakistan. The study focuses on technical, economic, and environmental aspects through the following key objectives:

Evaluate Mechanical Performance:

Assess how varying percentages of plastic waste (9%, 11%, and 13%) affect the strength, durability, and deformation resistance of asphalt mixtures. Standard laboratory tests such as Marshall Stability, Indirect Tensile Strength (ITS), Rutting Resistance, and Fatigue Life are used to determine mechanical performance under simulated field conditions.

Analyze Impact of Aggregate Gradation:

Investigate the effect of different aggregate gradations (well-graded, coarse, and fine) on the mechanical behavior of plastic-modified asphalt. The goal is to determine the optimal gradation that enhances interlock, reduces voids, and improves mix stability based on NHA Class-A specifications.

Assess Load-Bearing Capacity:

Evaluate whether plastic-modified mixes can support legal axle loads, especially those of 22-wheeler trucks carrying up to 60 tons. Wheel tracking tests are used to confirm rutting resistance and structural adequacy for high-traffic routes.

Cost Efficiency and Economic Analysis:

Compare life cycle costs of plastic-modified asphalt with conventional asphalt used in Pakistan. The study aims to demonstrate that plastic roads—particularly with plastic content—are more economical in the long run due to reduced maintenance, lower bitumen usage, and longer pavement life. Results show savings of PKR 2.9–3.1 million per kilometer over a 20-year span.

Environmental Sustainability and CO2 Reduction:

Analyze how using plastic in roads diverts waste from landfills and reduces environmental pollution. The project quantifies annual CO2 savings through both bitumen replacement and plastic recycling. For 100 km of road with plastic, about 15,120 tons of plastic waste is reused, and CO2 emissions are reduced by approximately 97,070 tons per year.

Align with Sustainable Development Goals (SDGs):

Support Pakistan’s progress toward SDG 9 (Industry and Infrastructure), SDG 11 (Sustainable Cities), SDG 12 (Responsible Consumption), and SDG 13 (Climate Action). The project contributes to cleaner cities, efficient waste use, and climate-resilient infrastructure.

Develop Practical Guidelines:

Recommend best practices for plastic waste collection, processing, and integration into asphalt production. Propose steps for standardization, pilot testing, and training to enable widespread implementation across Pakistan’s road network.

Socio-Economic Benefit

The implementation of plastic waste-modified asphalt in road construction offers significant socio-economic benefits for Pakistan, addressing both infrastructure and environmental challenges while supporting national development goals. The following points summarize the key socio-economic advantages:

1. Cost-Effective Road Construction

Plastic-modified roads, especially with 9% plastic content, reduce long-term construction and maintenance costs.

Life cycle cost analysis shows a saving of PKR 2.9–3.1 million per kilometer over 20 years compared to conventional roads.

Lower maintenance frequency leads to reduced public expenditure and improved budget allocation for new infrastructure.

2. Employment Generation

Establishing a supply chain for collecting, sorting, and processing plastic waste can create jobs in the informal and formal sectors.

Municipal waste workers, recycling centers, and transportation services benefit from increased demand for plastic handling and logistics.

3. Environmental Pollution Reduction

Each kilometer of road with 9% plastic content diverts approximately 151,200 kg of plastic waste from landfills and water bodies.

This helps reduce urban flooding, improve sanitation, and promote healthier living conditions, especially in low-income areas.

Reduction of 97,070 tons of CO2 per year (for 100 km roads) helps mitigate climate change and improve air quality.

4. Infrastructure Longevity and Safety

Improved road durability reduces potholes and surface failures, enhancing safety for drivers and reducing accident rates.

Better roads improve transport efficiency and reduce vehicle operating costs such as fuel, tire wear, and suspension damage.

5. Boost to Local Recycling Industry

Demand for recyclable plastics encourages growth of local recycling businesses.

Encourages investments in recycling technologies and infrastructure, supporting a circular economy.

6. Support for Rural and Urban Connectivity

Cost savings can allow expansion of road networks into underdeveloped regions.

Improved roads increase access to education, healthcare, and markets, contributing to poverty alleviation and social mobility.

7. Contribution to National and Global Development Goals

Supports SDG 9 (Infrastructure & Innovation), SDG 11 (Sustainable Cities), SDG 12 (Responsible Consumption), and SDG 13 (Climate Action).

Positions Pakistan as a regional leader in green infrastructure solutions.

Methodologies

This project follows a structured methodology to investigate the performance of plastic waste-modified asphalt mixtures using different aggregate gradations. The approach includes material collection, laboratory testing, performance analysis, and cost evaluation. The steps are outlined below:

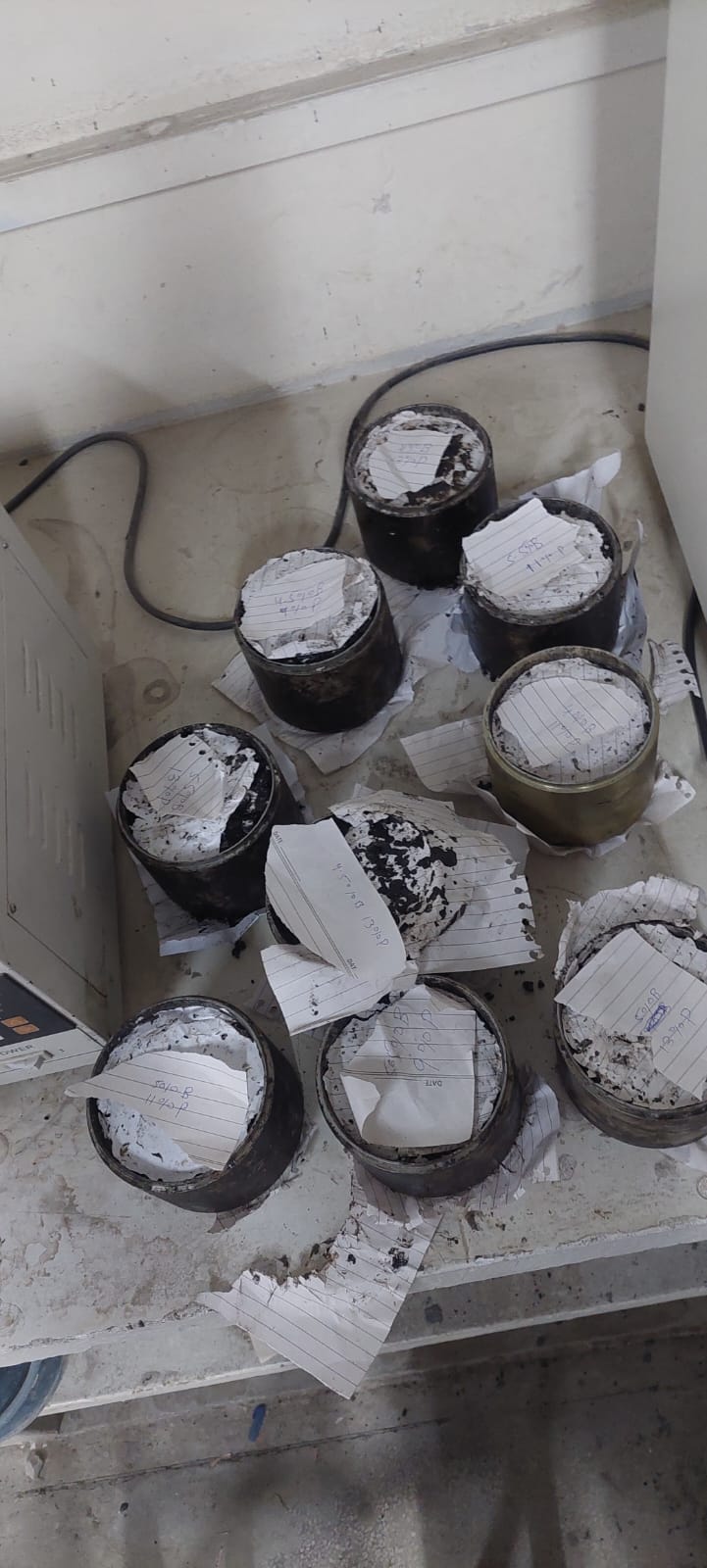

1. Material Collection and Preparation

Plastic Waste:

Collected from municipal waste facilities. Common plastics like PET, PP, and PS were selected for their availability and compatibility with asphalt.

Cleaning: Plastic was washed to remove dirt and contaminants.

Shredding: Cut into small pieces for uniform mixing.

Drying: Removed all moisture to prevent mixing issues.

Aggregates:

Sourced from local quarries (e.g., Margalla) and tested for compliance with ASTM/AASHTO standards.

Gradation: Sieved and categorized into well-graded, coarse, and fine.

Washing: Ensured dust-free aggregates for proper bonding.

Bitumen:

Conventional 60/70 penetration grade asphalt binder, commonly used in Pakistan, was used as the base material.

2. Modification of Asphalt Binder

Heated bitumen to 160–170°C.

Added shredded plastic (9%, 11%, 13% by weight of binder).

Used a mechanical stirrer for uniform plastic dispersion.

Tested modified binder for viscosity, softening point, and ductility.

3. Mix Design (Marshall Method)

Followed the Marshall Mix Design method for preparing asphalt samples.

Heated aggregates and mixed with plastic-modified binder.

Molded and compacted using a Marshall hammer (75 blows per side).

Samples were prepared for each plastic content with varying aggregate gradations.

4. Laboratory Testing

Marshall Stability and Flow Test:

Evaluated strength and deformation characteristics under compressive load.

Indirect Tensile Strength (ITS):

Measured cracking resistance under tensile stress.

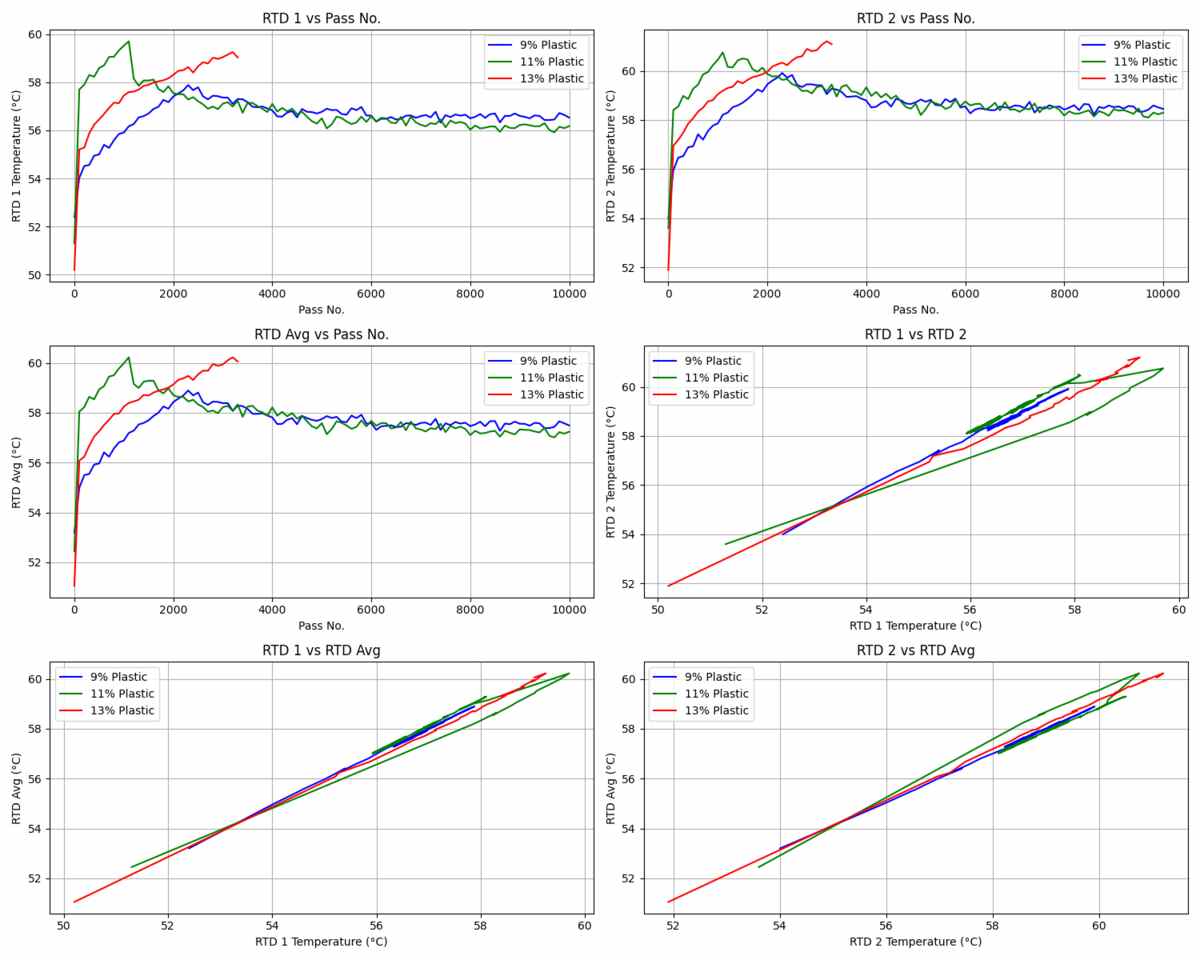

Rutting Resistance Test:

Conducted wheel tracking tests at 60°C to simulate traffic loads. Recorded rut depths over repeated passes.

Fatigue Test:

Assessed pavement durability under cyclic loading.

Water Sensitivity Test:

Measured tensile strength ratio (TSR) before and after moisture exposure to assess durability in wet conditions.

5. Data Analysis

Recorded all results for stability, flow, ITS, rutting, fatigue life, and TSR.

Used statistical methods like ANOVA and regression analysis to identify trends and relationships.

Compared performance across different plastic percentages and gradation types.

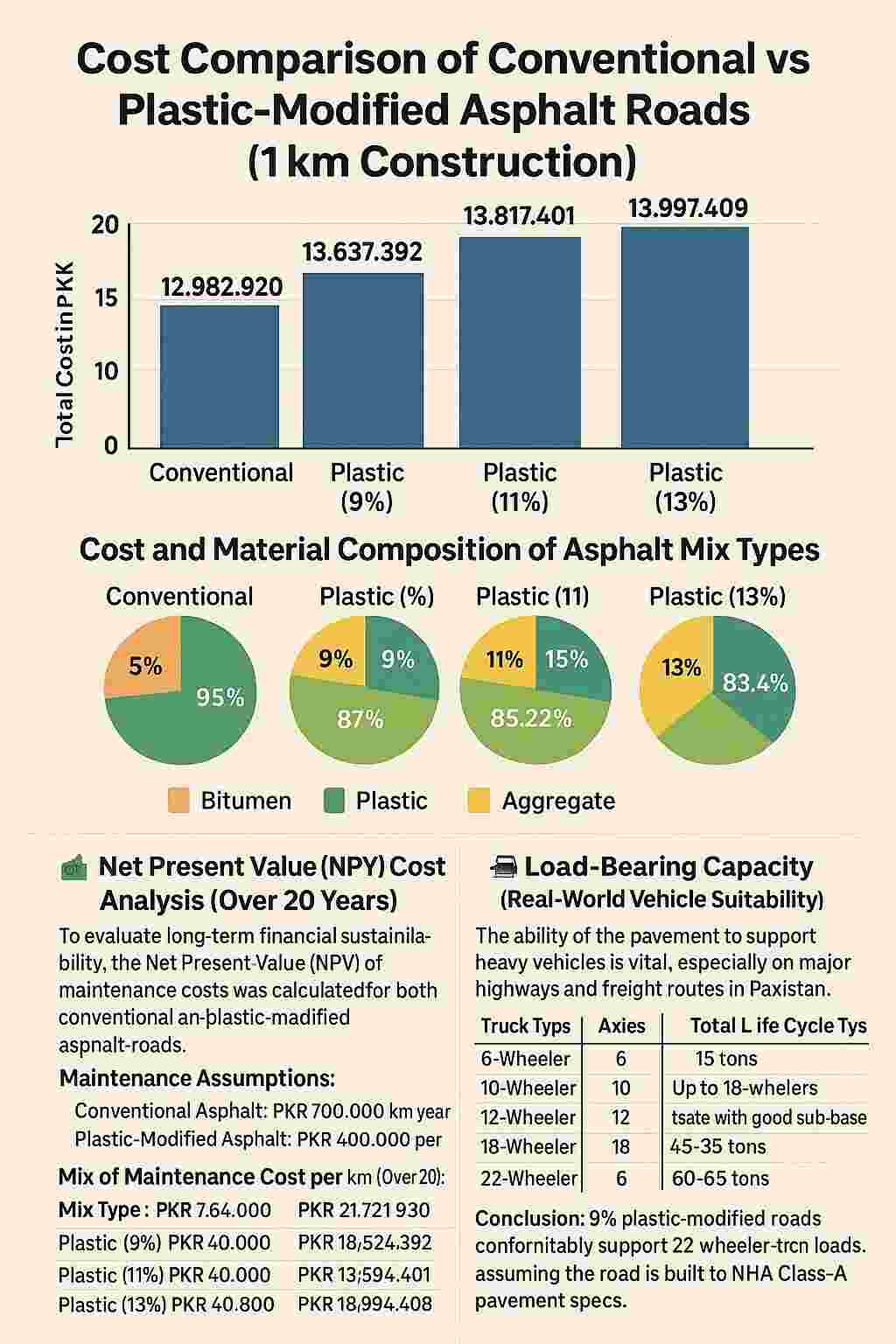

6. Life Cycle Cost and Sustainability Analysis

Calculated construction and maintenance costs over a 20-year life span.

Used Net Present Value (NPV) for economic comparison.

Evaluated environmental benefits including CO2 reduction and plastic waste reuse.

This methodology ensures a thorough assessment of plastic-modified asphalt mixtures, enabling recommendations for real-world applications in Pakistan’s road infrastructure.

Outcome

The project successfully investigated the use of plastic waste-modified asphalt mixtures for road construction in Pakistan, focusing on mechanical performance, cost-effectiveness, environmental impact, and structural suitability. The key outcomes are summarized below:

1. Optimal Plastic Content Identified

Among the tested plastic contents (9%, 11%, and 13%), 9% plastic waste proved to be the most effective.

It provided the best balance of strength, rutting resistance, and durability without compromising workability or causing deformation.

2. Enhanced Rutting Resistance

The Wheel Tracking Test showed that the 9% plastic mix had a rut depth of only 3.9 mm after 10,000 passes, indicating excellent deformation resistance.

The 11% mix showed acceptable performance (5.4 mm), while the 13% mix exceeded limits (13.72 mm), making it unsuitable for heavy-traffic roads.

3. Strong Load-Bearing Capacity

The 9% and 11% plastic mixes could safely support axle loads of up to 60 tons, making them suitable for heavy vehicles such as 22-wheeler trucks, provided pavement thickness and sub-base comply with NHA Class-A standards.

4. Economic Benefits Over Conventional Roads

The life cycle cost analysis revealed that plastic-modified roads offer PKR 2.9–3.1 million savings per kilometer over 20 years.

Lower maintenance costs and reduced bitumen usage contribute to this economic advantage.

5. Environmental Impact Reduction

Using 9% plastic per kilometer diverts 151,200 kg of plastic waste from landfills.

For 100 km of road, this results in 15,120 tons of reused plastic and 97,070 tons of CO2 reduction annually through bitumen savings and plastic recycling.

6. Role of Aggregate Gradation

Well-graded aggregates, combined with 9% plastic-modified binder, delivered the highest stability and durability.

Proper gradation improved interlocking, reduced voids, and enhanced load distribution.

7. Alignment with SDGs

The project supports several UN Sustainable Development Goals:

SDG 9 – Industry, Innovation, and Infrastructure

SDG 11 – Sustainable Cities and Communities

SDG 12 – Responsible Consumption and Production

SDG 13 – Climate Action

8. Practical Implementation Potential

The results demonstrate that plastic-modified asphalt is technically viable, economically beneficial, and environmentally sustainable.

It can be integrated into Pakistan’s road construction standards with proper processing, mix design, and training.

In conclusion, the project proves that plastic waste-modified asphalt, paired with proper aggregate gradation, offers a durable, cost-efficient, and eco-friendly solution for road infrastructure development in Pakistan.