This study presents a machine learning (ML)-based framework to predict five critical properties of recycled concrete aggregate (RCA) concrete: Chloride Ion Penetration (CIP), Slump, Compressive Strength (CS), Splitting Tensile Strength (STS), and Modulus of Elasticity (MOE). These properties significantly influence the performance, durability, and sustainability of concrete in modern construction. Traditional testing methods are time-consuming, costly, and labor-intensive. By leveraging large-scale datasets and advanced ML models such as Random Forest (RF), Support Vector Machines (SVM), Artificial Neural Networks (ANN), and Gradient Boosting, this study provides accurate predictive tools that minimize the need for repeated physical testing. The models show strong accuracy across all properties, supporting faster decision-making, sustainable construction practices, and enhanced design efficiency aligned with UN Sustainable Development Goals (SDGs).

Objectives

Objective

The primary objective of this research is to develop and validate predictive machine learning models for:

• Chloride Ion Penetration (CIP) – to evaluate durability and corrosion resistance.

• Slump – to estimate workability and ensure mix consistency.

• Compressive Strength (CS) – to predict load-bearing capacity without long curing delays.

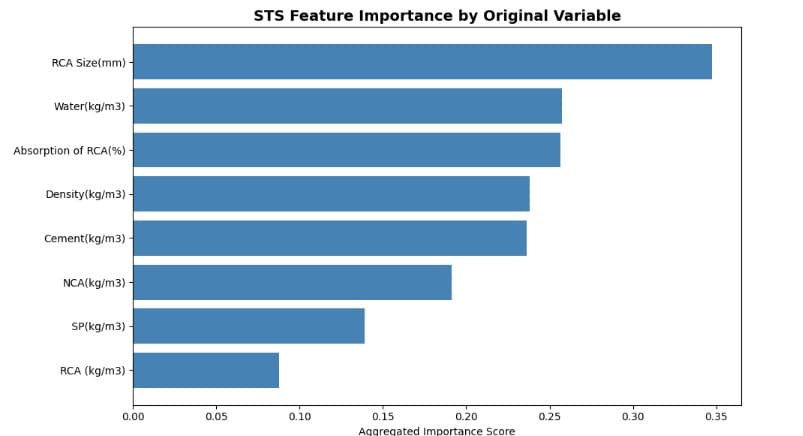

• Splitting Tensile Strength (STS) – to assess tensile resistance and cracking potential.

• Modulus of Elasticity (MOE) – to determine stiffness and deformation behavior.

This objective supports the reduction of laboratory testing, encourages the efficient use of recycled aggregates, and advances sustainable design methodologies.

Socio-Economic Benefit

Socio-Economic Benefits

1. Cost Reduction:

o Significant savings in material and labor by reducing physical tests.

o Avoids repeated trial-and-error mix adjustments.

2. Time Efficiency:

o Accelerates construction timelines by enabling early predictions (e.g., CS without 28-day wait).

3. Sustainability Promotion:

o Encourages use of RCA, reducing demand for virgin aggregates.

o Minimizes environmental impact via reduced testing and waste.

4. Improved Durability and Safety:

o Accurate CIP and MOE predictions support safer, longer-lasting infrastructure.

5. Digital Innovation in Construction:

o Fosters adoption of AI/ML in civil engineering, improving industry competitiveness.

6. Policy and Regulatory Support:

o Data-backed tools can assist policymakers in defining standards for recycled materials.

These benefits collectively support greener, faster, and more economical construction while enhancing the structural integrity of concrete infrastructure.

Methodologies

Methodology

1. Data Collection:

o Large datasets collected for each property:

? CIP: 1136 datapoints

? Slump: 1,087 data points.

? CS: 2,072 data points.

? STS: 539 data points.

? MOE: 420 data points.

2. Feature Engineering:

o Selected features: water, cement, aggregates, RCA %, admixtures, fiber, superplasticizers, curing time, compressive strength, SCMs, etc.

o Identified most influential variables for each output.

3. Model Training:

o Applied algorithms including RF, SVM, ANN, Decision Trees, XGBoost, and Gaussian Process Regression.

o Used cross-validation and train-test splits for model reliability.

4. Optimization:

o Hyperparameter tuning to maximize model performance.

o Iterative refinement to reduce noise and enhance accuracy.

The methodology ensures that each ML model is robust, generalizable, and suitable for practical implementation.

Outcome

Outcomes

• High Prediction Accuracy:

o CIP, CS, STS, and MOE models achieved R² values above 0.9.

o Slump models predicted workability trends effectively.

• Development of Predictive Tools:

o Interactive tools for CIP, STS, and MOE predictions developed for engineering use.

• Reduced Dependency on Physical Testing:

o Accurate predictions without 28-day delays or destructive methods.

• Support for Sustainable Design:

o Models validated across RCA mixes, promoting circular economy.

• Scalability:

o Framework adaptable to different concrete compositions and geographic conditions.

The outcomes directly contribute to more efficient and sustainable concrete construction practices.