In this project, the use of Graphite Nano Platelets (GNPs) in Recycled Coarse Aggregate Concrete (RCAC) is experimentally studied. Using recycled aggregate benefits the environment and contributes to preserving natural aggregate. Recycled Coarse Aggregate (RCA) was obtained from demolished concrete structures. The percentages of Natural Coarse Aggregate (NCA) replaced with RCA were 30, 60, and 100%, whereas the percentages of GNPs added were 0.1, 0.2, 0.3, and 0.4% of the weight of cement. According to the test results, when the proportion of RCA was increased compared to the control mix, slump, compressive strength, splitting tensile strength, flexural strength, and ultrasonic pulse velocity (UPV) decreased due to higher porosity, weaker interfacial transition zone, surface impurities, irregular size and shape of RCA. However, the addition of GNPs to RCAC enhance the mechanical properties up to 0.3% of GNPs content. After 0.3%, the properties started decreasing due to the accumulation

Objectives

To determine the combined effects of Graphite Nano Micro Platelets (GNMPs) as an additive and recycled aggregate concrete (RAC) as replacement with coarse aggregates.

To determine the optimum dosage of RAC and GNMPs.

Socio-Economic Benefit

Recycled Aggregate Concrete is a waste product while Graphite Nano/Micro Platelets are obtained from metamorphic rocks. Thus, RAC has relatively lower cost than GNMPs. So, incorporating both into the concrete will create a balance between cost reduction by RAC and cost increase by GNMPs.

Saving of valuable land

One step closer to sustainability

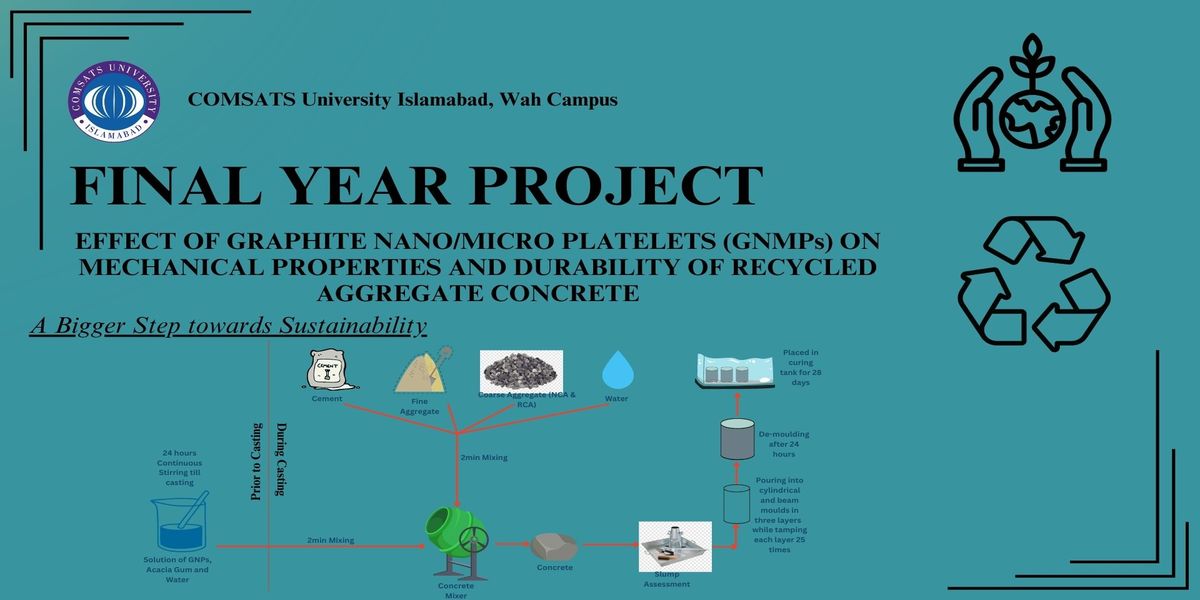

Methodologies

This diagram depicts the methodological process. The process commenced with the utilization of mixed proportions, subsequently transitioning to trial mixes and conducting requisite examinations to verify the accomplishment of desired outcomes. Following attaining the desired outcome, the samples were casted and the properties of the control mixture and other mixtures were evaluated.

Outcome

The slump test result shows that the increase in RAC percentage the slump decreases while with the increase in GNMPs it increases. From the compressive strength, Splitting tensile strength and ultrasonic pulse velocity test it can be seen that with the increase in percentage of RAC the mechanical properties and durability decrease and with the increase in GNMPs it increase. The maximum Strength is achieved at 0.3% GNMPs.