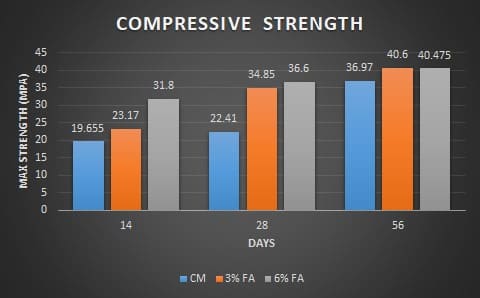

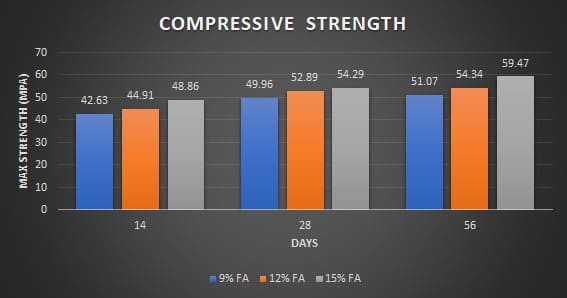

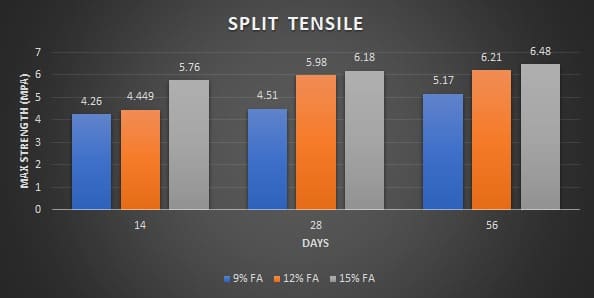

Reactive Powder Concrete (RPC) is a type of ultra-high-performance concrete characterized by its high compressivestrength. So, this project aims to develop reactive powder concrete by combination of cement, silica fume, super plasticizer andsteel fibers. The developed RPC’s mechanical performance is studied by conducting experiments to study its compressive strength,tensile strength and flexural strength. Then, fly ash is used as replacement of cement by adding 3%, 6%, 9%, 12% and 15%proportions to enhance RPC’s binding characteristics and makes it eco-friendly and more economical and also enhances thestrength of the RPC.

Objectives

1- Developing RPC

2-To measure compressive strength of different mixes at ages

3- To measure split tensile of different mixes at ages

4-To measure durability of different mixes

Socio-Economic Benefit

The socio economic benefits of this project includes:

reduction in the amount of waste that is produced in the construction industry.

Fly ash is a waste product from coal-fired power plants, so using it in concrete could help to reduce the need for other, more expensive materials. This could lead to lower construction costs, which could benefit both businesses and consumers.

Additionally, the use of fly ash in concrete could also have environmental benefits. Fly ash can sometimes leach harmful chemicals into the environment, so using it in concrete could help to reduce this problem.

Methodologies

1- Reviewing previous studies to understand the use of locally available materials for the production of RPC.

2- Selecting materials that contribute to achieving sustainability in the concrete industry and are available locally for the production of reactive powder concrete.

3- Casting mixtures to obtain the optimum proportions for the production of reactive powder concrete.

4- Samples are tested for their strength and durability through compression and splitting tensile tests. The results are then visualized in graphs using Microsoft Excel.

Outcome

1- RPC with 15% fly ash achieved optimum strength as compare to all other mixes.

2- For all mixes, maximum compressive strength achieved after 56 days of ambient curing.