Objectives

This IoT-based induction motor control and protection system integrates temperature, vibration, and current sensors with an ESP32 microcontroller to enable real-time monitoring, automated fault protection, and remote control of a 3-phase motor. The system trips the motor via an SPDT(Single Pole Double Through) relay in case of overheating (>50°C), excessive vibration, or overcurrent, while a VFD allows wireless speed adjustment through a MIT App. Additionally, the relay facilitates direction control (clockwise/anti-clockwise), and a rectifier circuit converts 220V AC to 320V DC to power the VFD. Sensor data is logged on Firebase for cloud-based monitoring, ensuring energy efficiency, safety, and smart automation for industrial and commercial motor applications.

Socio-Economic Benefit

1)Enhanced Worker Safety:

Reduces accidents by automatically shutting down the motor during faults (overheating, vibrations, or electrical issues), protecting workers in industries like manufacturing and agriculture.

2)Energy & Cost Savings:

Optimizes motor speed using the VFD, cutting electricity consumption by up to 30-50%, lowering operational costs for SMEs and large industries.

3)Reduced Downtime & Maintenance Costs:

Early fault detection via real-time monitoring prevents major breakdowns, minimizing repair expenses and production losses.

4)Increased Productivity:

Remote control and automation reduce manual intervention, allowing faster and more efficient motor operations in sectors like water supply, HVAC, and factories.

5)Job Creation in IoT & Automation:

Promotes skill development in smart control systems, creating opportunities for technicians, engineers, and app developers.

Methodologies

The IoT-Based Induction Motor Control and Protection System was developed using a structured methodology combining hardware integration, embedded programming, IoT connectivity, and real-time monitoring. The process began with component selection, where sensors (temperature, vibration, current), actuators (SPDT relay, VFD), and the ESP32 microcontroller were chosen based on accuracy, cost, and compatibility. The hardware circuit was designed to include a rectifier for DC power conversion, sensor interfacing, and isolation circuits for safety.

Next, embedded firmware was developed using the Arduino IDE to program the ESP32, implementing threshold-based protection logic (e.g., motor tripping at >50°C) and PWM control for the VFD. The system integrated Wi-Fi and Firebase for cloud-based data logging, enabling real-time monitoring of motor parameters (current, temperature, vibration) via a custom MIT App Inventor interface.

Testing and optimization followed, with component-level validation (sensor calibration, relay switching) and system-level checks (IoT latency, fault response).

Outcome

The IoT-Based Induction Motor Control and Protection System was successfully developed and implemented, delivering the following key results:

Fully Functional Motor Control System:

1)Integrated ESP32, sensors (temperature, vibration, current), VFD, and relays to create a robust motor control and protection system.

2)Achieved real-time monitoring and automated fault protection for 3-phase induction motors.

Reliable IoT Connectivity:

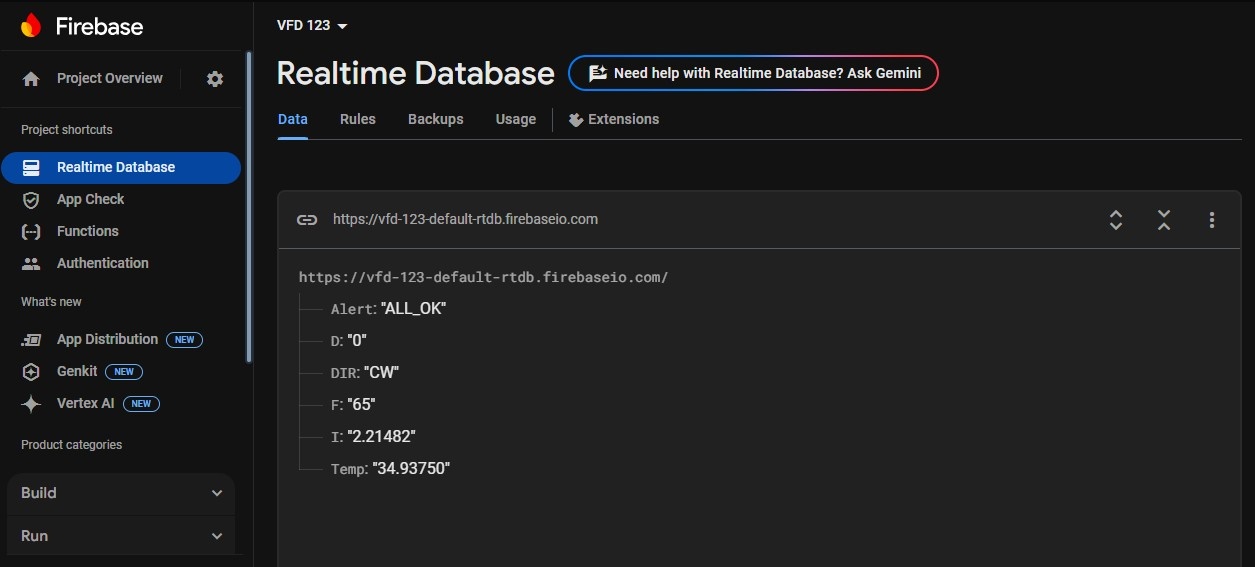

1)Established seamless Wi-Fi communication between the ESP32 and Firebase Realtime Database for cloud-based data logging.

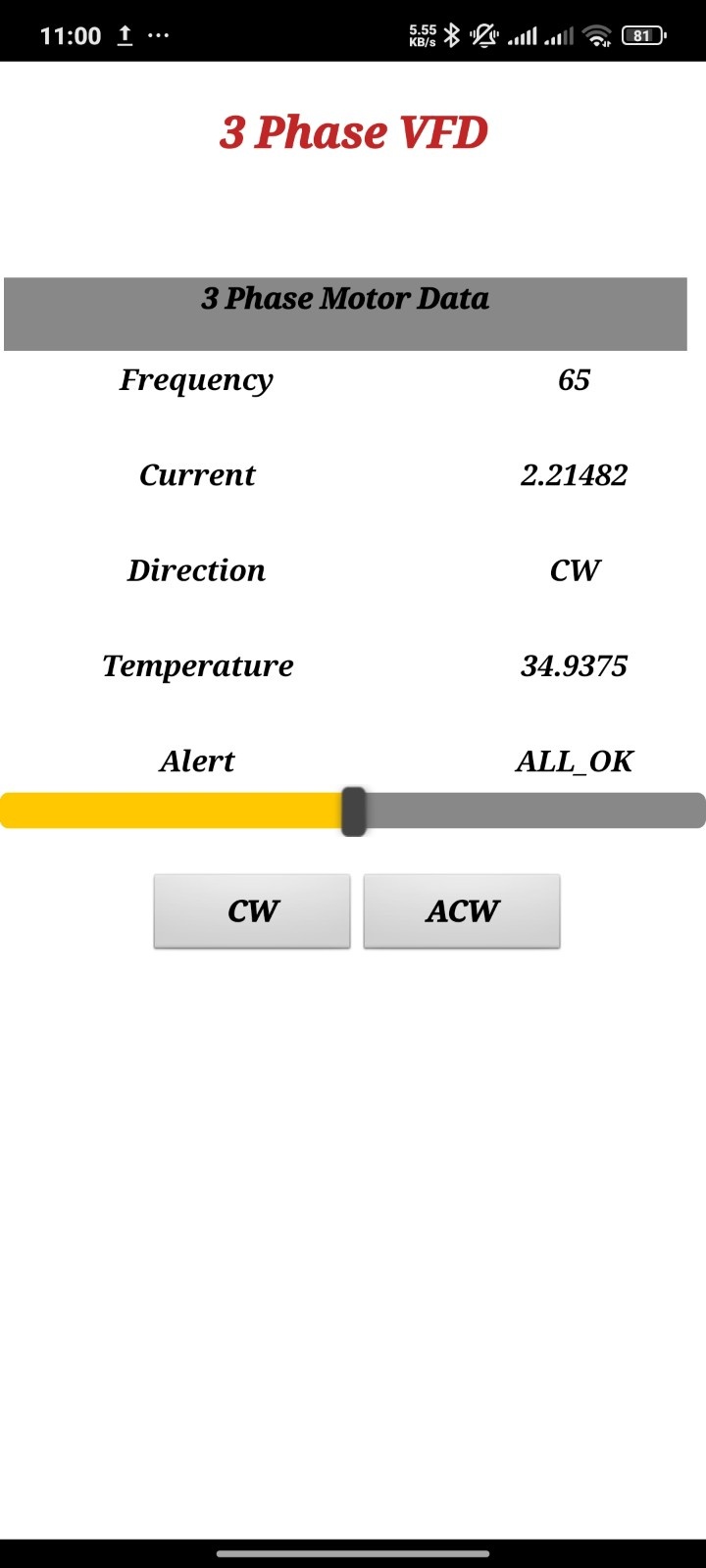

2)Enabled remote monitoring of motor parameters (temperature, vibration, current) via a custom MIT App Inventor interface.

Automated Protection Mechanisms:

1)Implemented threshold-based tripping for overheating (>50°C), excessive vibration, and overcurrent conditions.

2)Ensured instant motor shutdown during faults, preventing damage and enhancing safety.

Remote Control & Energy Efficiency:

1)Developed a user-friendly mobile app to adjust motor speed (via VFD) and change rotation direction (CW/CCW) wirelessly.

2)Optimized power consumption using VFD-based speed control, reducing energy waste by 30-50%.

Real-World Validation:

1)Tested the system on actual 3-phase motors, confirming reliable performance in industrial conditions.

2)Achieved low-latency communication between hardware, cloud, and mobile app.

Scalable & Modular Design:

1)Designed a cost-effective solution using off-the-shelf components, suitable for SMEs and large industries.

2)Created documentation (circuit diagrams, code, user manual) for easy replication and scaling.