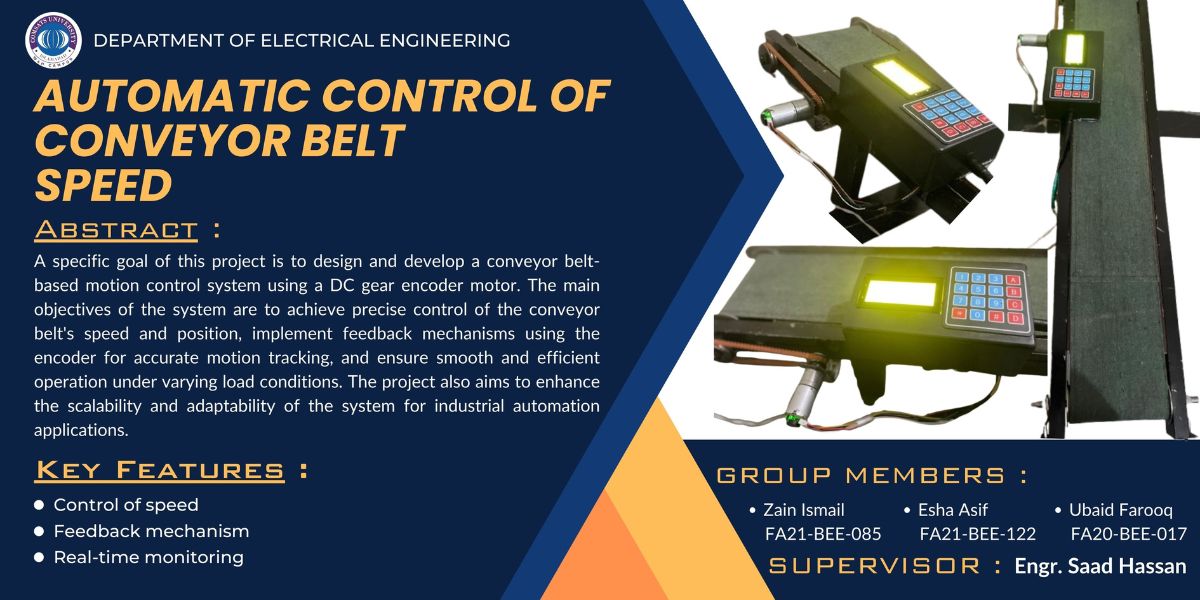

Automatic Control of Conveyor Belt Speed involves a control system (like a microcontroller etc) to monitor variables such as load, speed, or material flow. Based on these inputs, the system adjusts the motor speed automatically to optimize performance, reduce energy consumption, and prevent overloading or material spillage.

Objectives

Here are some key objectives for a project on Automatic Control of Conveyor Belt Speed:

To automate the speed control of a conveyor belt based on real-time load or material flow.

To improve energy efficiency by adjusting motor speed according to demand.

To prevent overloading and reduce spillage, ensuring smooth and safe operation.

To increase system reliability and reduce maintenance costs by minimizing wear and tear.

To enhance productivity through consistent and optimized material handling.

To integrate sensors and a control unit (like a PLC, Arduino, or microcontroller) for real-time feedback and control.

To develop a user-friendly interface for monitoring and manual override if necessary.

Socio-Economic Benefit

Here are some socio-economic benefits of the Automatic Control of Conveyor Belt Speed project:

Increased Operational Efficiency: Reduces downtime and energy use, lowering overall production costs and making industries more competitive.

Job Skill Enhancement: Promotes technical training and upskilling of workers in automation and control systems, leading to better employment opportunities.

Energy Conservation: Efficient motor control cuts electricity use, reducing industrial carbon footprint and supporting environmental sustainability goals.

Reduced Material Waste: Precise control prevents spillage and overloading, conserving raw materials and saving money.

Improved Workplace Safety: Automation reduces human intervention in hazardous areas, decreasing the risk of accidents and injuries.

Boosts Local Economy: Adoption of such technologies can stimulate related sectors like manufacturing, maintenance services, and automation training centers.

Methodologies

Here are the project methodologies for the Automatic Control of Conveyor Belt Speed project:

Problem Identification and Requirement Analysis

Study existing conveyor systems and identify inefficiencies.

Define system requirements (e.g., load range, speed range, sensor types).

System Design and Planning

Develop block diagrams and control logic.

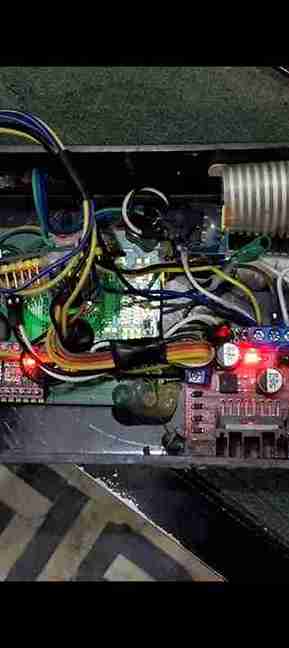

Select hardware components: sensors (load or IR), microcontroller/PLC, motor driver, and conveyor motor.

Hardware Implementation

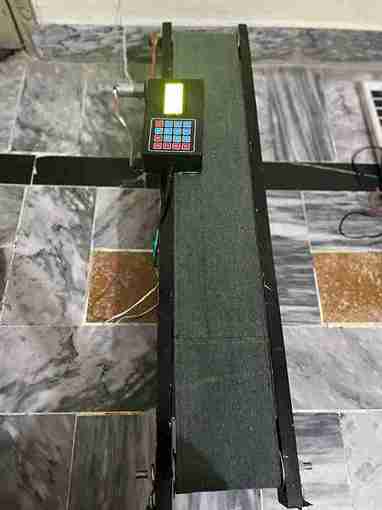

Assemble the conveyor belt setup with sensors and motor.

Interface the sensors and motor with the controller.

Software Development

Write control code (e.g., in Arduino IDE or ladder logic for PLC).

Implement algorithms to adjust speed based on sensor input.

Integration and Testing

Integrate hardware and software components.

Test under various load conditions to ensure stable speed control.

Optimization and Troubleshooting

Fine-tune control parameters for efficiency.

Resolve any functional or safety issues.

Documentation and Reporting

Prepare technical documentation, user manual, and final report.

Include diagrams, test results, and conclusions.

Outcome

Here is the Project Outcome for the Automatic Control of Conveyor Belt Speed:

Functional Prototype: A working conveyor system that automatically adjusts belt speed based on real-time input (e.g., load or material flow).

Improved Efficiency: Demonstrated reduction in energy usage and smoother material handling compared to a fixed-speed system.

Enhanced Safety: Reduced risk of overloading, spillage, and manual intervention, contributing to safer operations.

Scalable Design: A modular and adaptable system that can be applied to various industrial environments.

User Interface: Optional control panel or display for monitoring and manual override.

Skill Development: Practical experience in automation, sensor integration, programming, and system troubleshooting for the project team.