Our project focuses on the design and development of a plastic pyrolysis plant that aims to convert waste plastic into valuable products such as fuel oil, gas, and char. A key feature of our project is the use of catalysts—specifically magnesium oxide (MgO), zinc oxide (ZnO), and aluminum oxide (Al2O3)—to enhance the efficiency and selectivity of the pyrolysis process. These catalysts help reduce the reaction temperature, improve fuel yield, and increase the overall economic viability of the process.The plant design includes essential components such as a feedstock chamber, reactor, condenser, gas collection unit, and residue collection system. This project not only contributes to sustainable waste management but also promotes the concept of a circular economy by converting non-recyclable plastic into usable energy sources. It integrates principles from thermodynamics, chemical engineering, and mechanical design, providing a multidisciplinary learning experience.

Objectives

To design and fabricate a small-scale pyrolysis plant for

converting plastic waste into fuel.

To utilize and compare the performance of catalysts (MgO, ZnO,

and Al2O3) in the pyrolysis process.

To reduce the environmental impact of plastic waste through

thermal degradation.

To evaluate the fuel yield, quality, and efficiency of the process

with different catalysts.

To promote sustainable waste management and alternative

energy generation.

To apply principles of thermodynamics, chemical reactions, and

mechanical design in a practical engineering project.

To demonstrate the technical and economic feasibility of

catalytic pyrolysis at a small scale.

Socio-Economic Benefit

Reduction in Plastic Pollution: Helps clean the environment by

converting non-recyclable plastic waste into useful products.

Alternative Fuel Source: Produces low-cost fuel that can reduce

dependency on imported fossil fuels.

Job Creation: Promotes employment opportunities in waste

collection, plant operation, and fuel distribution.

Economic Uplift of Informal Sector: Supports local waste pickers

and recyclers by adding value to collected plastic.

Energy Access for Rural Areas: Provides a decentralized energy

solution for communities with limited energy access.

Cost-Effective Waste Management: Offers a sustainable and

affordable method for municipalities to manage plastic waste.

Encouragement of Green Entrepreneurship: Opens avenues for

small-scale businesses in renewable energy and recycling sectors.

Health Improvements: Reduces risks related to open burning

and dumping of plastic waste, leading to cleaner surroundings and

better public health.

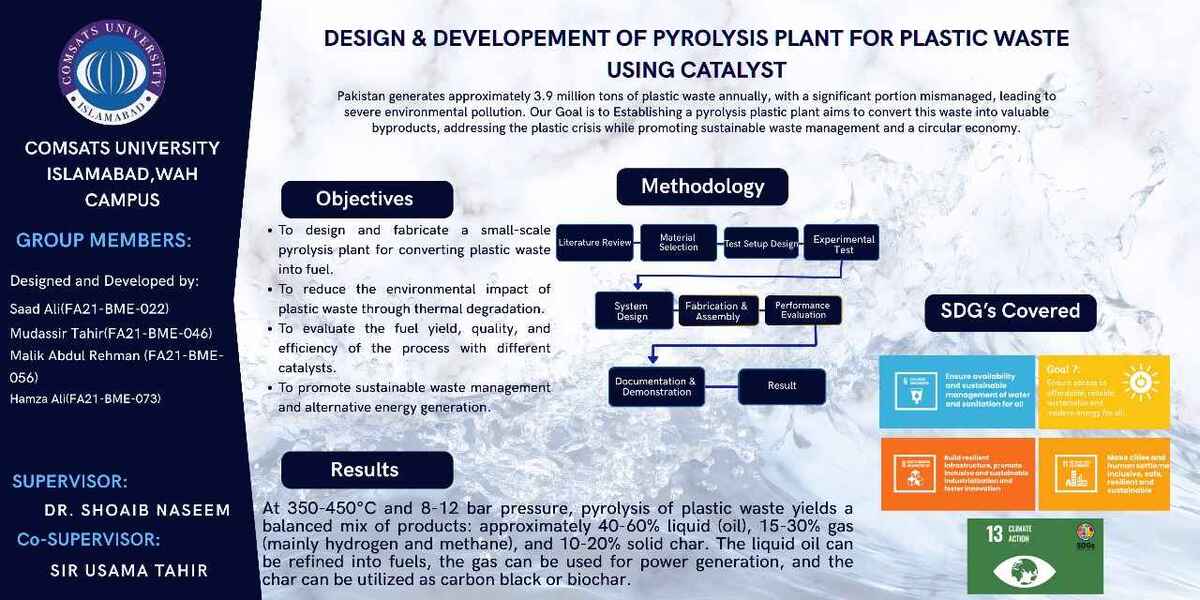

Methodologies

Methodology:

The methodology of this project involves a systematic approach

combining design, experimentation, and analysis to develop a

functional plastic pyrolysis plant. The process can be divided into

several key stages: material collection, plant design, catalyst

selection, experimental setup, pyrolysis reaction, and product

analysis.

1. Plastic Waste Collection and Preparation:

The first step involves collecting different types of plastic waste,

primarily polyethylene (PE), polypropylene (PP), and polystyrene

(PS), which are common in household and industrial waste

streams. These plastics are sorted, cleaned to remove

contaminants, and shredded into small uniform pieces (typically

1–2 cm) to ensure consistent thermal decomposition during

pyrolysis.

2. Design and Fabrication of Pyrolysis Plant:

A batch-type pyrolysis reactor was designed using basic principles

of heat transfer, material strength, and thermal insulation. The

main components include:

A reactor chamber made of stainless steel for

withstanding high temperatures.

A heating system (electric or gas burner) to supply

controlled heat to the reactor.

A condenser unit for cooling and collecting pyrolysis

vapors into liquid fuel.

A gas collection chamber to separate non-condensable

gases.

A char collection unit for solid residues.

The system is thermally insulated to minimize heat loss, and

temperature sensors are installed to monitor the reaction.

3. Catalyst Selection and Preparation:

Three catalysts—magnesium oxide (MgO), zinc oxide (ZnO), and

aluminum oxide (Al2O3)—are selected based on their known

catalytic activity, thermal stability, and cost-effectiveness. These

catalysts are ground to a fine powder and mixed with the plastic

feedstock at different ratios (e.g., 5–10% by weight) before being

fed into the reactor. Each catalyst is tested separately in different

batches for performance comparison.

4. Pyrolysis Process:

The reactor is sealed and heated in the absence of oxygen to

initiate the pyrolysis reaction. The temperature is gradually

increased to around 400–500°C, depending on the type of plastic

and catalyst used. As the plastic decomposes, vapors are produced

and passed through the condenser. The condensed vapors are

collected as pyrolysis oil, while non-condensable gases are

captured and, if sufficient, recycled as fuel for heating. The

remaining char is collected at the bottom of the reactor.

Each batch is run under controlled conditions to ensure safety and

repeatability. Multiple experiments are conducted with each

catalyst to determine the optimal operating temperature,

reaction time, and catalyst-to-plastic ratio.

5. Product Analysis:

The pyrolysis oil is analyzed for its physical and chemical

properties, including density, viscosity, calorific value, and

composition (via gas chromatography). The effectiveness of each

catalyst is evaluated based on: Oil yield (%), Reaction time Energy efficiency.

Outcome

This project involves the design and development of a small-scale

plastic pyrolysis plant to convert waste plastic into useful fuel

products. The pyrolysis process thermally decomposes plastic in

the absence of oxygen, producing fuel oil, gas, and char. To

enhance the efficiency and fuel yield, the project incorporates

catalysts such as magnesium oxide (MgO), zinc oxide (ZnO), and

aluminum oxide (Al2O3). The plant is designed for batch operation

and includes components like a reactor, condenser, and gas

collection unit. The project aims to offer an eco-friendly, cost

effective solution to plastic waste management while contributing

to alternative energy production. It also provides valuable insights

into sustainable engineering practices.