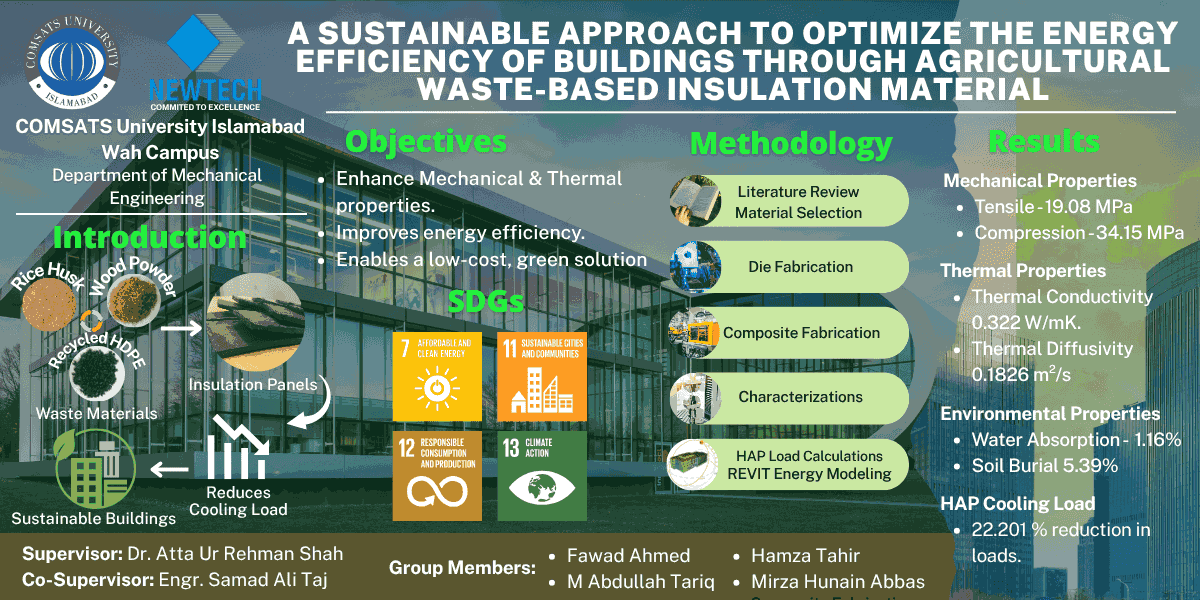

This project develops sustainable insulation material using waste materials to enhance building energy efficiency. The rising demand for eco-friendly insulation, the study uses locally sourced materials from Pakistan, including rice husk, wood powder, and recycled HDPE. Nine compositions were designed, with the optimized mix (60% R-HDPE, 20% Rice Husk, 20% Wood Powder) showing a tensile strength of 19.08, compression strength 34.15 MPa, thermal conductivity 0.321 W/mK, thermal diffusivity of 0.18 m2/s, water absorption 1.16%, and soil burial degradation of 5.39%. Fabrication involved manual mixing, extrusion, and injection molding, with a custom die manufactured at COMSATS University Islamabad, Wah Campus. Mechanical, thermal, and environmental tests confirmed the material’s durability and stability. HAP calculations show a 22.201% reduction in cooling loads of DME CUI Wah. It aligns with SDGs (7, 11, 12, 13). This cost-effective solution reduces waste and lowers energy costs.

Objectives

• To fabricate sustainable insulation material using agricultural waste (rice husk and wood powder) and recycled HDPE to enhance energy efficiency.

• To optimize the mechanical, thermal, and environmental properties of the insulation material to ensure durability and performance under environmental conditions.

• To reduce building cooling loads by implementing the developed insulation material, contributing to lower energy consumption.

• To manufacture a cost-effective and eco-friendly insulation solution that utilizes local waste materials to support environmental sustainability.

Socio-Economic Benefit

• The use of low-cost agricultural waste and recycled materials reduces insulation production costs, making energy-efficient buildings more affordable for communities.

• Local sourcing and production of insulation materials can generate employment opportunities in waste collection, processing, and manufacturing sectors.

• By converting agricultural and plastic waste, the project reduces waste and pollution, promoting a useful product that is safe for our environment.

• This project enhances the building energy efficiency, reduces electricity bills for households and businesses, enhancing economic savings and access to affordable energy.

Methodologies

This project involves the basic systematic approach for material selection, composite fabrication, and characterization. The following steps show the following details:

• Literature Review and Material Selection

We have conducted a comprehensive study of existing insulation materials to identify the merits and limitations of agricultural waste. Through our research, we found that rice husk and wood powder as fillers and recycled (HDPE) are the binder due to their availability, low cost, and eco-friendly properties.

• Design of Experiments

We use the Taguchi Design of Experiments (DOE) method via Minitab software to design material compositions, varying the proportions of rice husk, wood powder.

• Raw Materials

Raw materials were brought from the local Pakistani market, including rice husk, wood powder, and recycled HDPE from the local Pakistani Market, to ensure cost-effectiveness and accessibility.

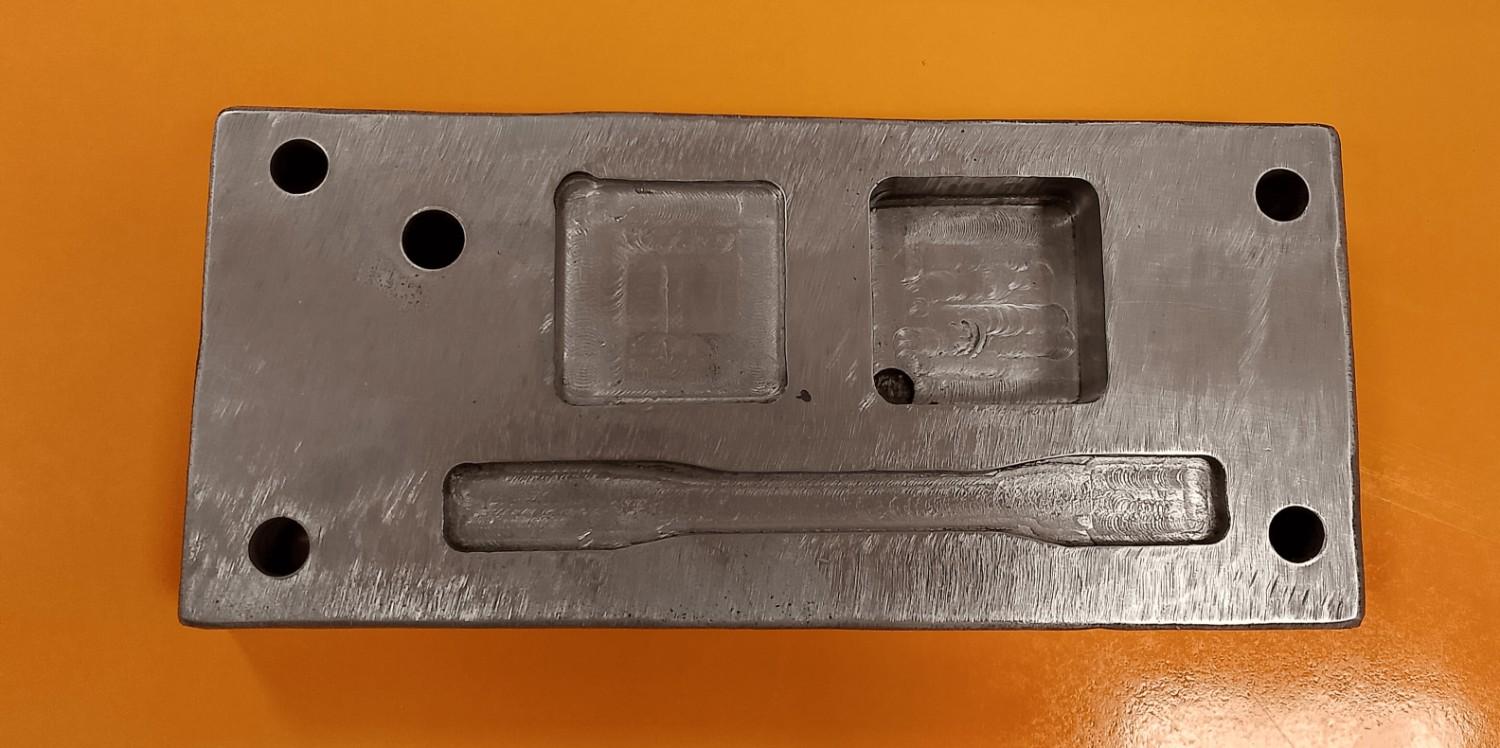

• Die Fabrication

A custom die for preparing tensile, water absorption, thermal, and compression testing samples was designed and manufactured using a Manual Vertical Milling Machine at COMSATS University Islamabad, Wah Campus. The die enabled the fabrication of samples composed of rice husk, wood powder, and recycled HDPE. This process ensured consistent sample dimensions for standardized testing per ASTM. The locally produced die supported cost-effective and efficient sample fabrication.

• Composite Fabrication

The composite fabrication includes the following process:

Manual Mixing: Mixed the rice husk, wood powder, and recycled HDPE in specified percentages by weight.

Manual Extrusion: The mixed compositions were manually extruded by using a meat mincer machine to produce the uniform composite pellets.

Hand Injection Molding: We used a custom-made die, manufactured on a Manual Vertical Milling Machine at COMSATS University Islamabad, Wah Campus, to mold the composite pellets into test samples.

• Material Characterization

We have conducted various mechanical, thermal, and environmental tests to evaluate the performance of the insulation material:

Tensile Strength: Tested using the ASTM D695 standard to assess material strength.

Compression Strength: Evaluated using ASTM D638 standard to determine load-bearing capacity.

Thermal Conductivity: Measured using ASTM C177 standard to confirm low heat transfer properties.

Water Absorption: Assessed using ASTM D570 standard to ensure minimal moisture uptake.

Soil Burial Test: Performed using ISO 17556 standard to verify environmental stability and biodegradability.

Outcome

A comprehensive characterization study was conducted to evaluate the mechanical, physical, and thermal properties of various composite formulations incorporating recycled high-density polyethylene (HDPE), wood powder, and rice husk. Among the tested compositions, the optimal blend was identified as containing 60% recycled HDPE, 20% wood powder, and 20% rice husk. This specific composition demonstrated the most balanced performance across all key parameters.

Mechanically, the composite achieved a tensile strength of 19.08 MPa, which indicates a robust structural integrity suitable for non-load-bearing construction applications. In terms of durability, the material exhibited a low water absorption rate of 1.16%, suggesting good resistance to moisture penetration—an essential property for building materials used in humid or outdoor environments. Soil burial degradation testing showed a weight loss of 5.39%, signifying a relatively stable material with moderate biodegradability, which is beneficial from an environmental sustainability standpoint.

Thermally, the composite recorded a thermal conductivity of 0.322 W/mK, highlighting its potential as a thermal insulator. Additionally, the thermal diffusivity was calculated at 0.1826 m²/s, indicating a relatively slow rate of heat propagation through the material. These thermal properties suggest that the composite can effectively minimize heat transfer, thereby contributing to improved energy efficiency in buildings.

To further validate the real-world impact of the material on energy consumption, the Hourly Analysis Program (HAP) was employed to assess its effect on building cooling loads. The simulation was carried out for the DME Cui Wah campus, considering climate conditions, building design, and typical usage patterns. The results were significant, revealing a 22.201% reduction in cooling loads when the composite was used in place of conventional materials. This considerable decrease highlights the composite’s potential to contribute to sustainable building practices by lowering reliance on mechanical cooling systems, thereby reducing energy demand and operational costs.

In conclusion, the composite made from 60% recycled HDPE, 20% wood powder, and 20% rice husk not only offers a sustainable approach to material reuse but also enhances building energy efficiency. Its favorable mechanical strength, low water absorption, moderate degradability, and excellent thermal performance, supported by HAP simulations, make it a promising material for eco-friendly construction and thermal insulation applications.