This project optimizes carbon fiber-reinforced nylon drone frames using FDM, combining RSM, AI, and generative design. We used Central Composite Design to vary infill density (20–80%), layer thickness (0.1–0.3 mm), and temperature (240–260°C) across 28 samples with gyroid and honeycomb infills. Generative design algorithms created topology-optimized models with high strength-to-weight ratios. AI models trained on test data predict mechanical performance, reducing trial-and-error. This approach delivers lightweight, durable, and cost-effective frames while supporting SDGs on innovation, sustainable production, and industry growth.

Objectives

• To optimize FDM process parameters (infill density, layer thickness, and print temperature) for PA6-CF material using Response Surface Methodology (RSM) and evaluate the mechanical performance across different infill patterns (gyroid and honeycomb).

• To develop and compare predictive models using RSM and machine learning techniques (RF, KNN, GPR, ANN) for accurately forecasting tensile strength and hardness of 3D-printed components.

• To integrate generative design for creating lightweight, structurally efficient drone frames, and validate material behavior through advanced experimental techniques such as Scanning Electron Microscope (SEM).

Socio-Economic Benefit

• By optimizing FDM 3D printing for drone frames using locally available composite materials, the project supports in-house production, reducing dependency on costly imported metal parts.

• Lighter and stronger drone frames with reduced material usage directly lead to more affordable and energy-efficient drones, making advanced aerial technologies more accessible for small businesses, startups, and research institutions.

• The integration of AI and generative design promotes the use of Industry 4.0 tools, encouraging innovation in Pakistan's manufacturing and engineering sectors, particularly in UAV (Unmanned Aerial Vehicle) technology.

• The findings and methodologies from this project can serve as a foundation for future academic research, encouraging multidisciplinary collaboration among students in engineering, materials science, and computer science.

Methodologies

Material:

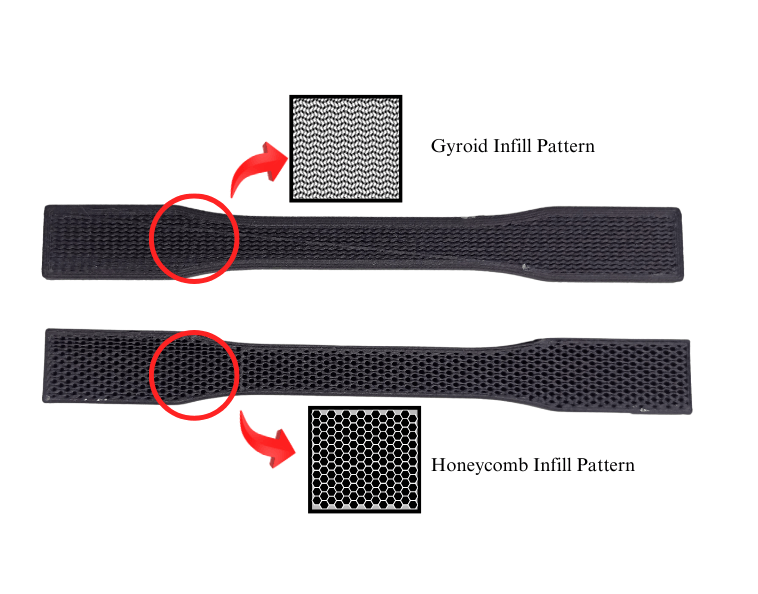

PA6-CF or Polyamide modified material with 15% carbon fiber and filament diameter of 1.75 mm was selected for this research due to its excellent tensile and impact strength, high-temperature resistance, low shrinkage and ease of printing.

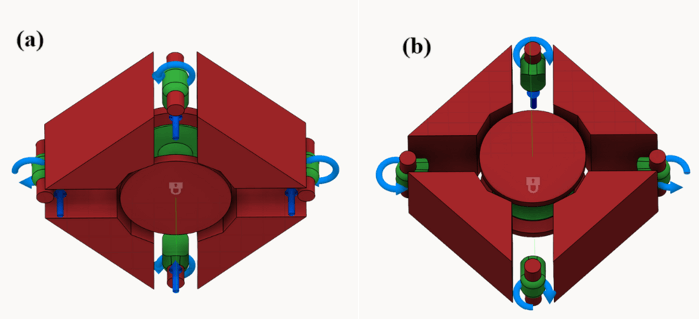

Design of Experiment (DoE):

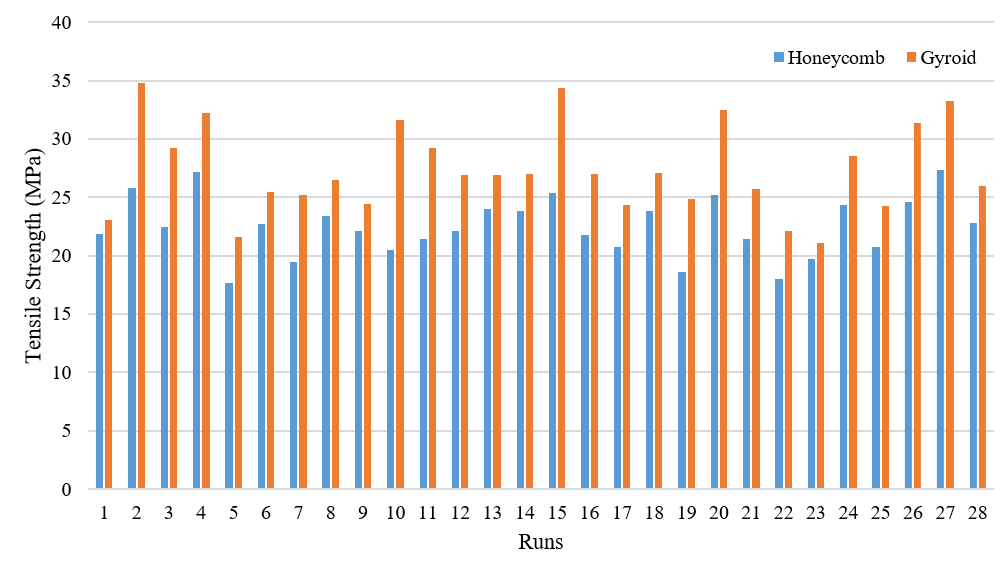

A Central Composite Design (CCD) with face-centered axial points (a = ±1) was used in RSM to investigate the effect of three input parameters namely, infill density, layer thickness and print temperature while using two infill patterns; honeycomb and gyroid. The design consisted of 28 experimental runs with 8 factorial points with 2 replicates (8 x 2=16), 6 axial (star) points and 6 center points to quantify curvature and experimental error.

Machine Learning Framework:

To validate the RSM results and compare the accuracy of RSM and AI, a set of traditional machine learning models namely Random Forest (RF), K-Nearest Neighbors (KNN), Gaussian Process Regression (GPR) and Artificial Neural Network (ANN) was used to predict the tensile strength of 3D-printed components. The prediction of each model was compared based on key evaluation metrics such as Mean Absolute Error (MAE), Root Mean Squared Errors (RMSE), and R² score.

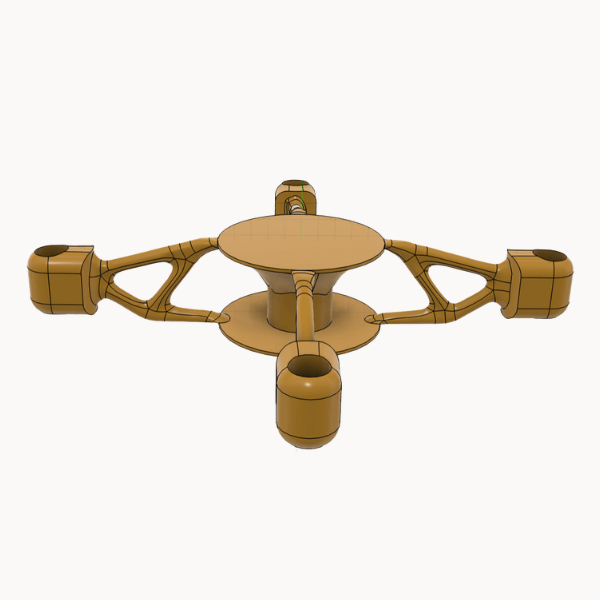

Generative Design:

In Fusion 360, we defined the design space, applied constraints, and set load conditions to simulate real-world forces. Material properties for carbon fiber-reinforced nylon were assigned to guide structural optimization. Multiple design iterations were generated and evaluated for strength-to-weight efficiency and FDM manufacturability.

Outcome

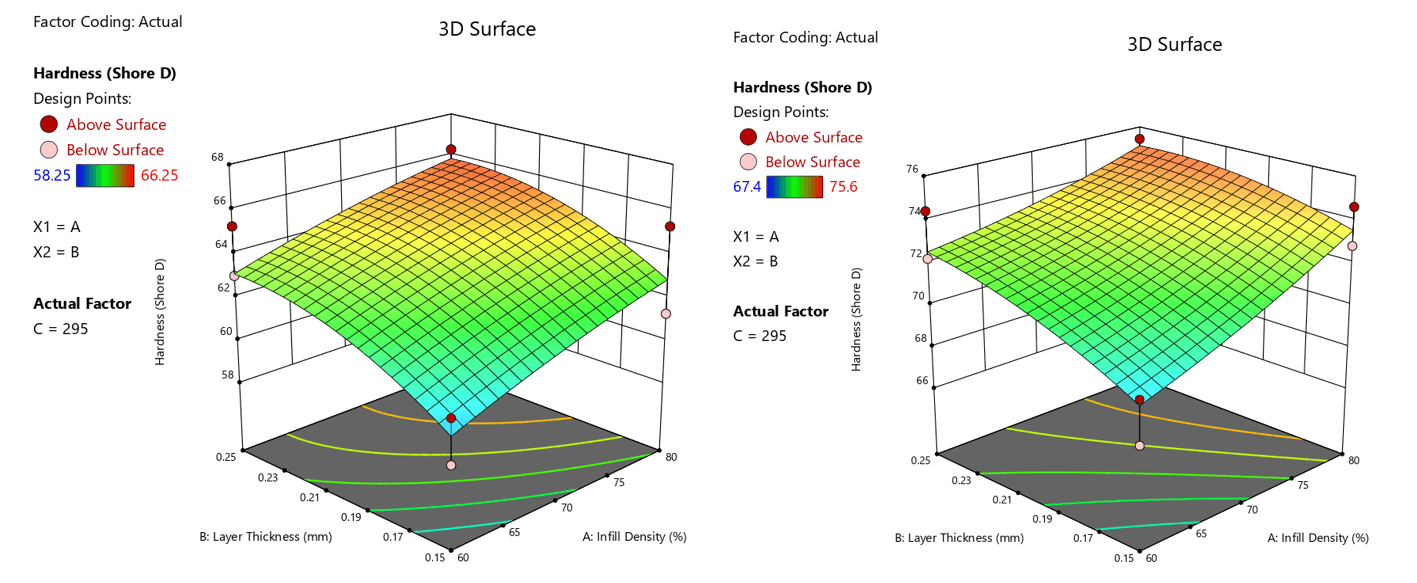

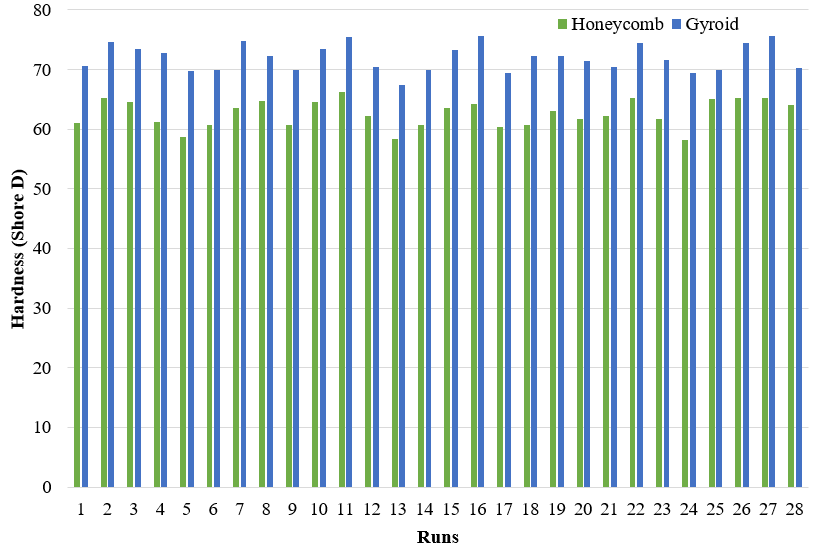

The experimental results demonstrated that tensile strength increased by 30.7% for samples with gyroid infill patterns, while hardness improved by 17.2% using the same pattern. Notably, we achieved equivalent tensile strength and hardness values with 60% infill density compared to 80% infill, leading to significant material savings and reduced weight, which is especially beneficial for drone frame applications.

By analyzing the effects of various input parameters, we identified which factors had the most significant influence on achieving optimal mechanical strength which can be visualized in 3D surface plots. Among the different machine learning models evaluated, the Random Forest model delivered the most accurate predictions, with the highest R² value and lowest MAE and RMSE, confirming its effectiveness in modeling the process-structure property relationship.

At this stage, additional material characterization test such as SEM (Scanning Electron Microscopy), was conducted to further analyze the microstructural and properties of the printed samples.