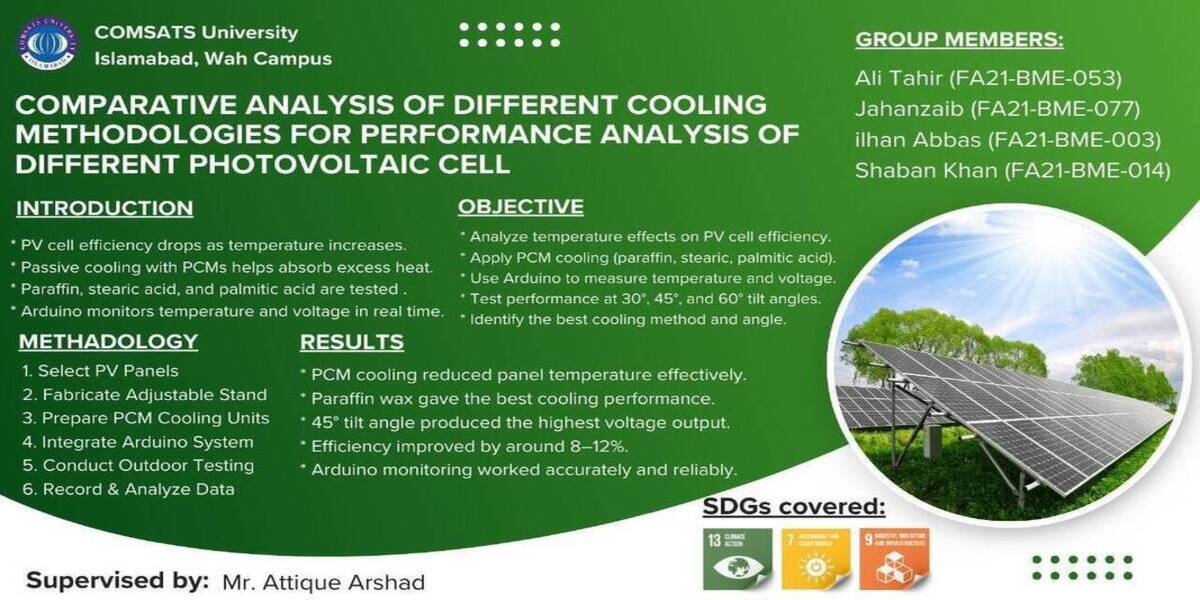

This project explores how different cooling methods can enhance the performance of photovoltaic (PV) cells, which tend to lose efficiency at high temperatures. It focuses on monocrystalline, polycrystalline, and thin-film PV technologies, comparing both passive (e.g., heat sinks, PCMs, natural convection) and active (e.g., forced air, water cooling, thermoelectric coolers) cooling techniques. Through experimental setups and simulations, the study will assess key performance indicators such as temperature, power output, efficiency, and energy yield. The goal is to identify the most effective and cost-efficient cooling strategies based on cell type, environmental conditions, and economic factors.

Objectives

• To analyze the impact of temperature on the performance of different types of photovoltaic (PV) cells (monocrystalline, polycrystalline, etc.).

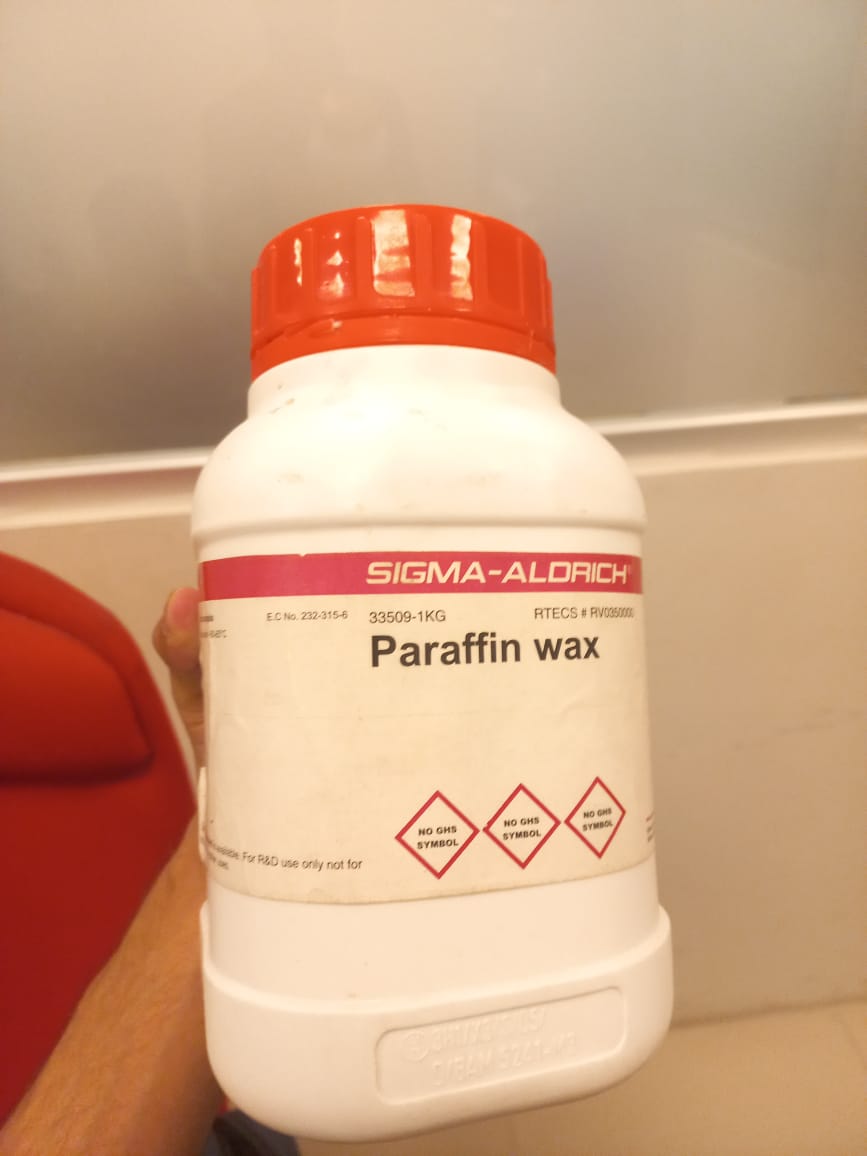

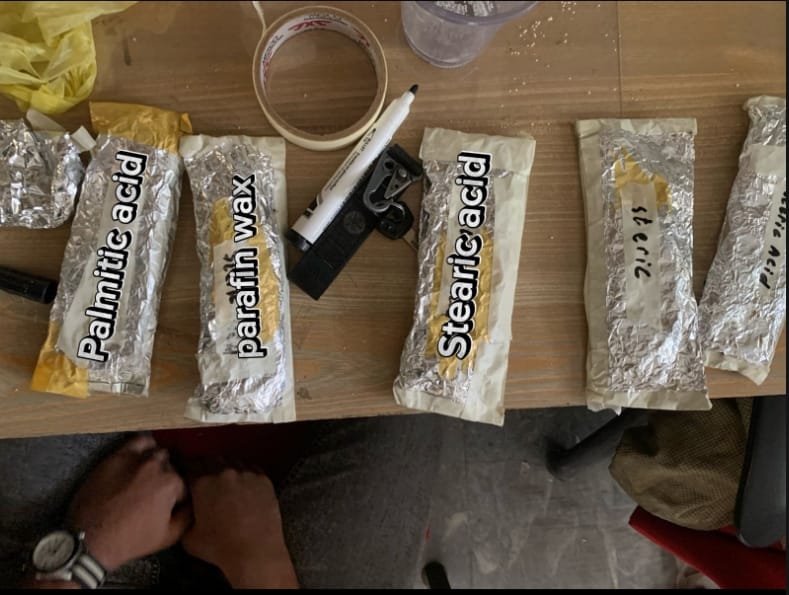

• To design and implement passive cooling systems using various Phase Change Materials (PCMs) such as paraffin wax, stearic acid, and palmitic acid.

• To develop a real-time monitoring system using Arduino for measuring temperature and voltage of PV cells.

• To evaluate the effectiveness of PCMs in reducing PV cell temperature and enhancing energy efficiency.

• To compare performance at different panel tilt angles (30°, 45°, 60°) using a custom-fabricated stand.

• To provide a cost-effective and scalable cooling solution for solar PV systems, especially in hot climatic regions.

• To identify the most efficient PCM material and optimal tilt angle combination for maximum power output.

Socio-Economic Benefit

• Increased Solar Efficiency: Enhancing the energy output of PV systems leads to greater electricity generation without additional panel area or cost.

• Low-Cost Cooling Solutions: Passive cooling using PCMs is affordable and requires no external energy, making it ideal for rural and off-grid areas.

• Sustainable Energy Access: Improved PV performance supports reliable solar power in energy-deprived regions, aiding in energy equity.

• Job Creation: Local fabrication of stands and PCM integration systems can generate employment in manufacturing, installation, and maintenance.

• Environmental Benefits: Increased solar efficiency reduces dependence on fossil fuels, supporting climate change mitigation efforts.

• Educational Impact: Encourages local academic institutions and students to innovate in renewable energy technology through hands-on research.

•Reduced System Payback Time: Higher efficiency means faster return on investment for solar installations, encouraging broader adoption.

Methodologies

1- Selection and Procurement of Components

• Choose different types of PV cells: Monocrystalline, Polycrystalline, and optionally Thin-film.

• Acquire Phase Change Materials (PCMs): Paraffin wax, Stearic acid, and Palmitic acid.

• Procure necessary electronics: Arduino, DS18B20 temperature sensors, voltage measurement circuits, and supporting components.

• Fabricate an adjustable tilt stand with angles of 30°, 45°, and 60° using arc welding for structural testing.

2- System Design and Setup

• Integrate the PV panels with and without PCM-based cooling systems.

• Enclose PCMs in heat-resistant aluminum or copper containers and mount them behind the PV panels.

• Connect temperature sensors to various locations:

o PV surface

o Ambient air

o PCM body

• Implement voltage divider circuits to safely monitor PV output voltage using Arduino.

3. Arduino-Based Data Acquisition

• Program Arduino to read temperature and voltage values in real-time.

• Store or display the data using an SD card module or serial monitor.

• Optional: use a Bluetooth/Wi-Fi module (e.g., ESP32) for wireless data logging.

4. Experimental Procedure

• Set up PV panels outdoors under natural sunlight.

• Test each configuration:

o Without PCM (baseline)

o With each PCM (paraffin, stearic acid, palmitic acid)

• Repeat tests at each tilt angle (30°, 45°, 60°).

• Record ambient conditions: temperature, irradiance (if pyranometer available), and wind.

5. Data Analysis

• Analyze PV output voltage and corresponding temperature.

• Calculate efficiency and thermal behavior for each cooling method and panel type.

• Compare performance across tilt angles and PCM types.

• Identify the best PCM and angle for maximizing efficiency.

Outcome

Successfully demonstrated the effectiveness of passive cooling using PCMs in improving PV cell performance.

Identified paraffin wax as the most efficient PCM for heat reduction.

Verified that tilt angle affects output, with 45° giving optimal voltage generation.

Developed a low-cost Arduino-based system for real-time monitoring of temperature and voltage.

Achieved 8–12% improvement in PV efficiency under PCM cooling.

Provided a scalable and energy-free cooling method suitable for hot climates and rural applications.