This project enhances a 1m wingspan BWB UAV's flight endurance using AI-driven surface optimization and composite reinforcement. Aiming for maximum lift-to-drag with minimal power, the design employs spline-based Bezier chord distributions optimized by machine learning. AI refines carbon fiber composite layups for improved strength-to-weight. Applications include low-power logistics, emergency gliding, and long-range relief. A cubic Bezier curve defines chord variation (300mm root to 150mm tip, ?˜0.5, AR˜7). CFD (ANSYS Fluent) analyzes aerodynamics. Fabrication uses 2x2 twill 3K carbon fiber/epoxy (vacuum bagging, multi-stage cure). Wind tunnel testing and strain measurements validate improved lift-drag and structural stability.

Objectives

The project's primary objective is to maximize the flight time and endurance of a 1 m wingspan BWB UAV powered by an undersized propulsion system by applying AI algorithms to generate optimized surface geometries and reinforce composite structures. This is achieved by improving the lift-to-drag ratio through AI-enhanced profiles, enabling the UAV to sustain longer flights on minimal propulsion, with applications in passenger aircraft emergency gliding, long-range medical and supply logistics, and other low-power aerial missions.

Socio-Economic Benefit

The project's description indicates that the combined AI-driven aerodynamic and structural enhancements support applications in low-power logistics, emergency gliding for passenger aircraft, and long-range medical and disaster relief missions.

Methodologies

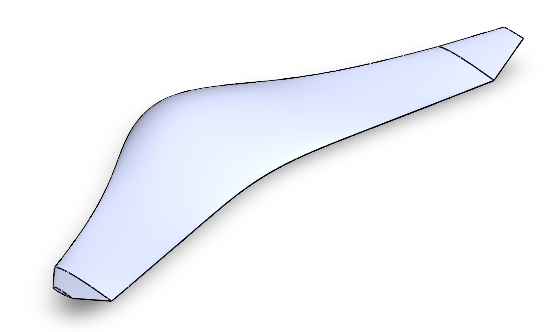

A 1m BWB UAV project maximizes endurance with four integrated components. Parametric geometry defines the design with a fixed 1m wingspan, planform (root/tip chord, taper, sweep, twist), and winglet (cant, sweep, root/tip chord) parameters. Airfoils (S1223 root, NACA 1408 mid, NACA 0012 tip) and a Bezier curve control chord distribution.

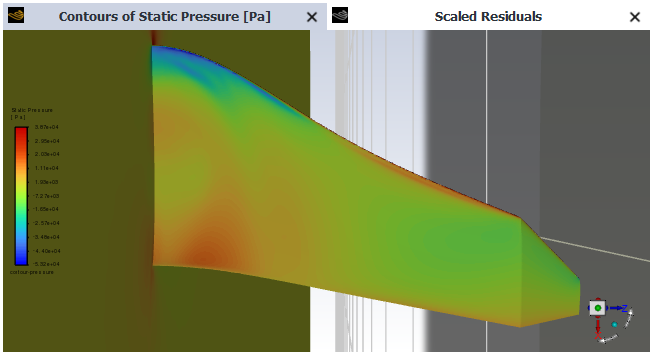

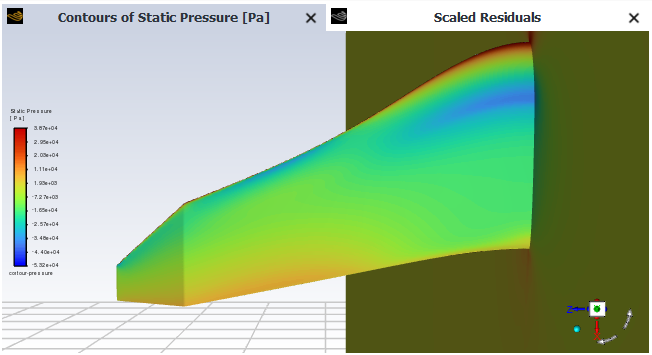

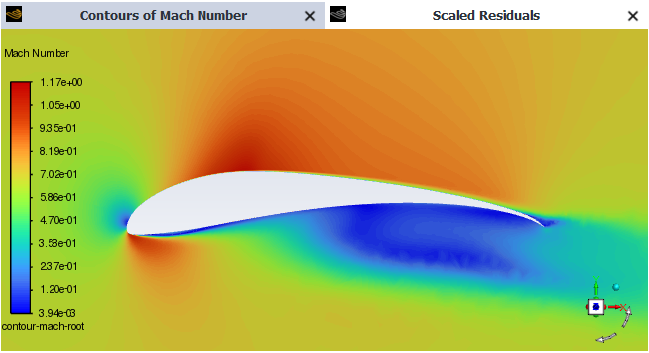

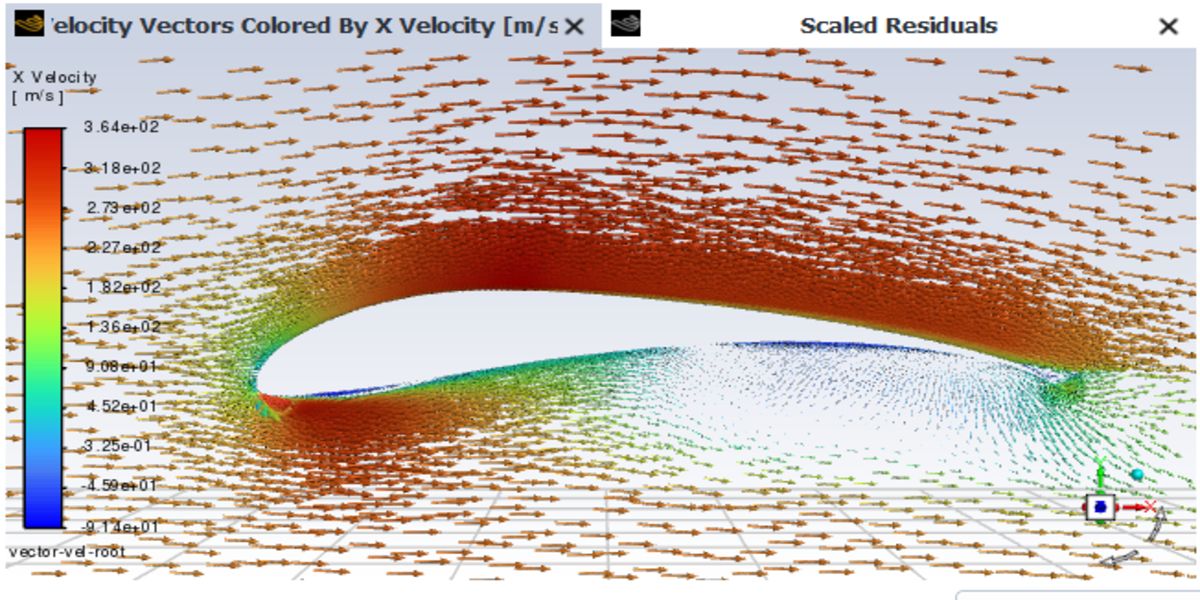

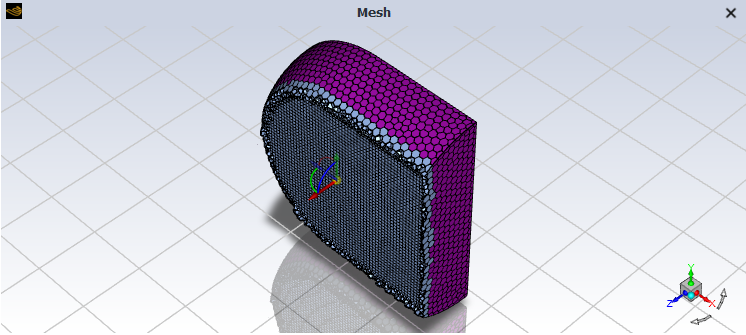

CFD evaluates aerodynamics at Mach 0.7 using RANS SST k-?, yielding non-dimensional CL, CD, and CP. A ~1.29M cell mesh ensures quality. Results feed the surrogate model for cruise speed (30 m/s) performance prediction.

AI-driven surrogate modeling employs GPR (R²˜0.96) trained on 60 LHS samples evaluated by CFD. Bayesian optimization with EI adds 20 designs, maximizing L/D while respecting CL,max and weight constraints. Sobol' indices identify key parameters.

Composite reinforcement uses carbon fiber (2x2 twill, unidirectional strips at critical areas) with vacuum bagging. FEA with shell and beam elements validates structural integrity under 2.5g loads (deflection < 1% span, Tsai-Wu < 1), ensuring optimized aerodynamics don't compromise the airframe and enhance endurance via weight reduction.

Outcome

This project tackles the challenge of extending the flight endurance of a Blended Wing Body (BWB) UAV powered by an undersized propulsion system. Traditional approaches focus on improving batteries or motors, but here we concentrate on AI-driven aerodynamic and structural optimization to maximize flight time on minimal power. Beginning with a parametric CAD model of the BWB geometry, including root/tip chords, sweep, taper, twist, and winglet design, we employed a cubic Bezier curve to ensure smooth chord distributions and blended airfoil transitions.

High-fidelity CFD simulations in provided baseline aerodynamic coefficients CL, CD . Using Latin Hypercube Sampling, we generated 60 initial designs and trained a Gaussian Process surrogate to predict L/D and drag-power coefficients. A Bayesian optimization loop with an Expected Improvement acquisition function then iteratively refined the design with only 20 additional CFD evaluations. Global Sobol’ sensitivity analysis revealed that sweep angle, taper ratio, and twist were the most influential parameters on performance.

The optimized geometry, maintaining a fixed 1 m span, achieved a increase in lift-to-drag ratio and a corresponding reduction in required drag power, directly translating to longer flight times under fixed motor output. A composite prototype, fabricated with 2×2 twill 3K carbon fiber and vacuum-bagged epoxy, was structurally validated via different tests, confirming its ability to withstand loads with minimal deflection.

By combining AI-assisted surrogate modeling with rigorous CFD and composite fabrication, this work delivers a scalable methodology for designing energy-efficient UAVs under tight propulsion constraints.